Sir Isaac Newton Knows Bowling

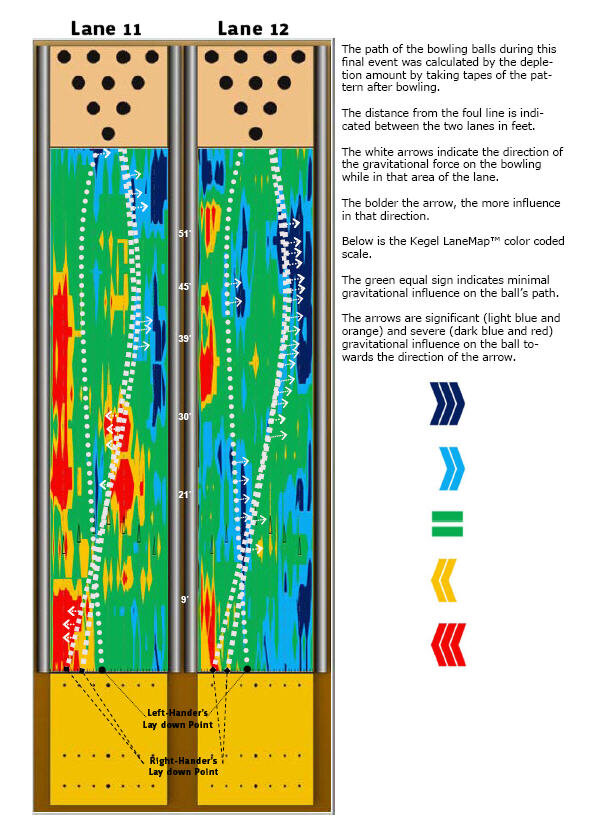

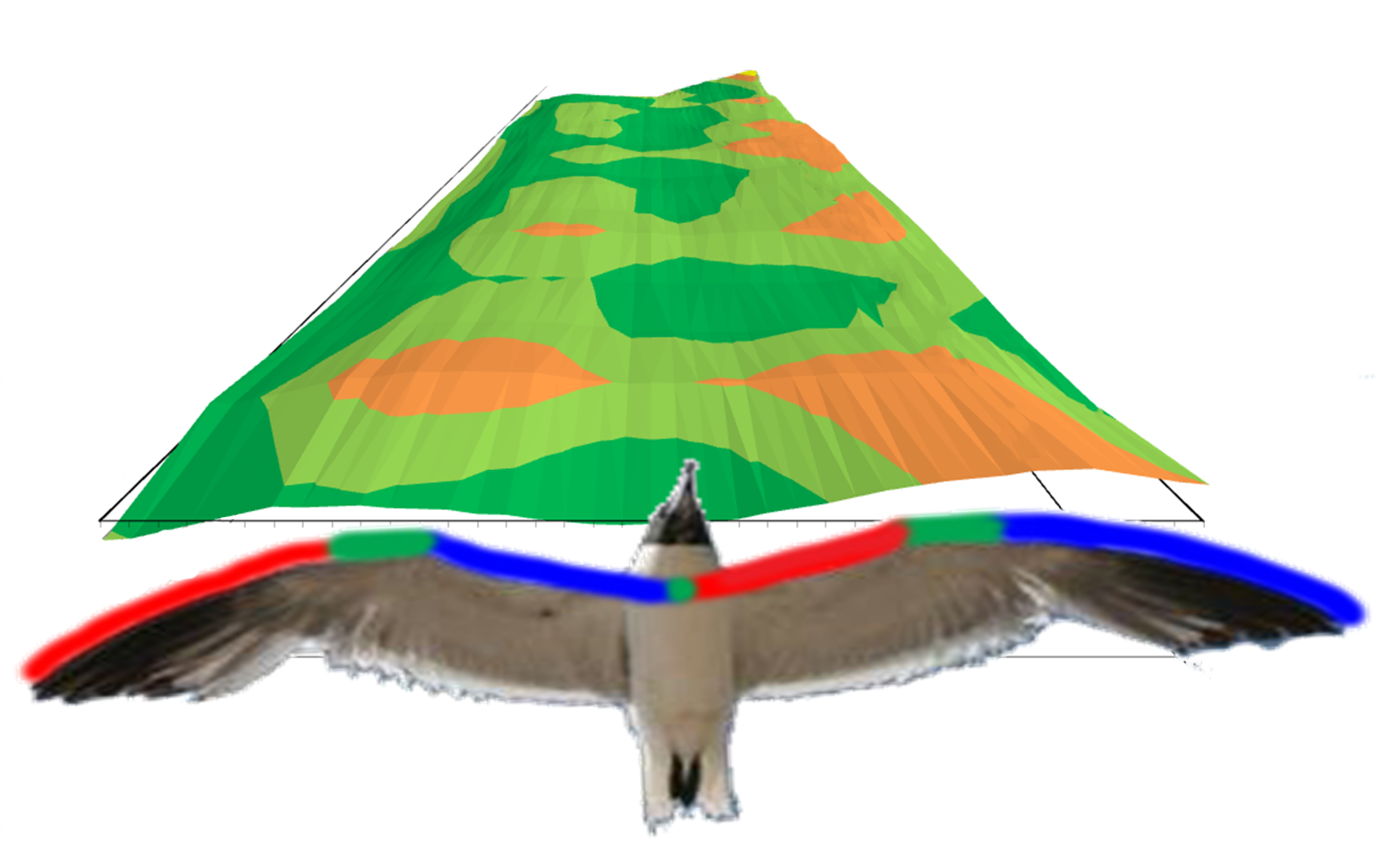

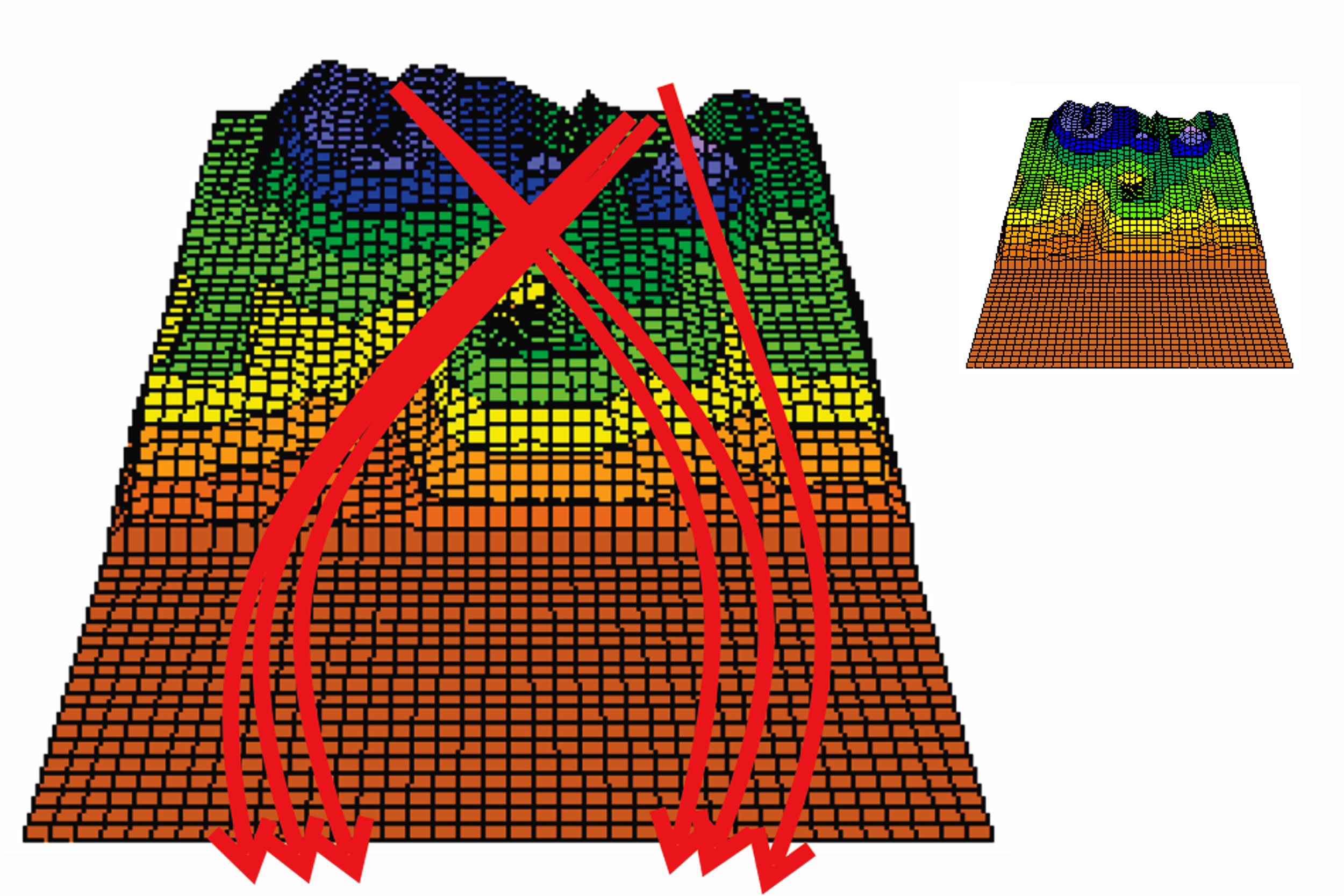

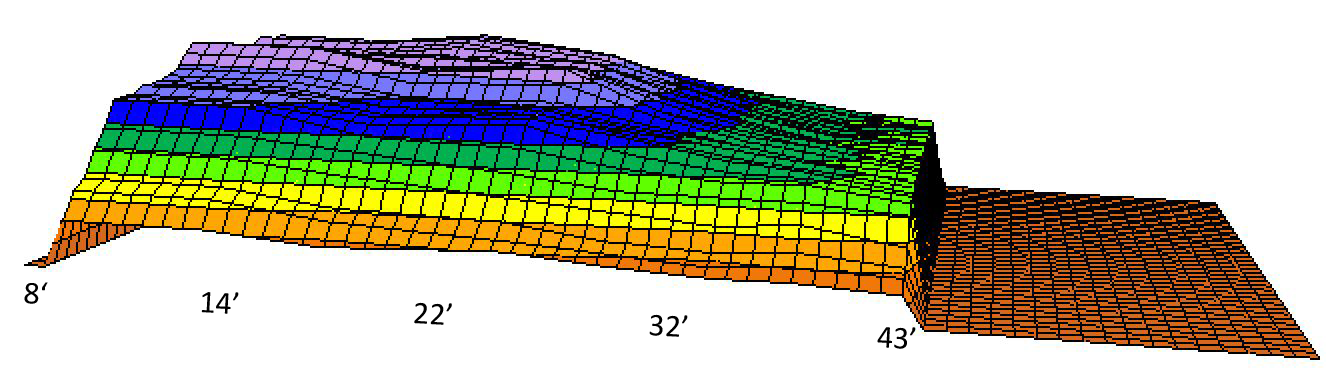

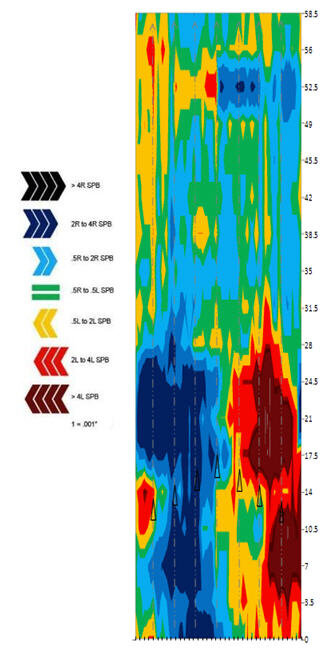

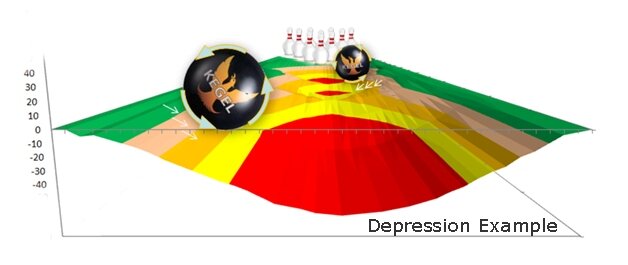

Sometimes pictures, or in this case a picture and a video, explains it best. The video below is the championship match of the Trio’s event at the recently concluded WTBA World Men’s Championship. The picture is the Kegel LaneMap™ of lanes 11-12 at Dream Bowl Palace.

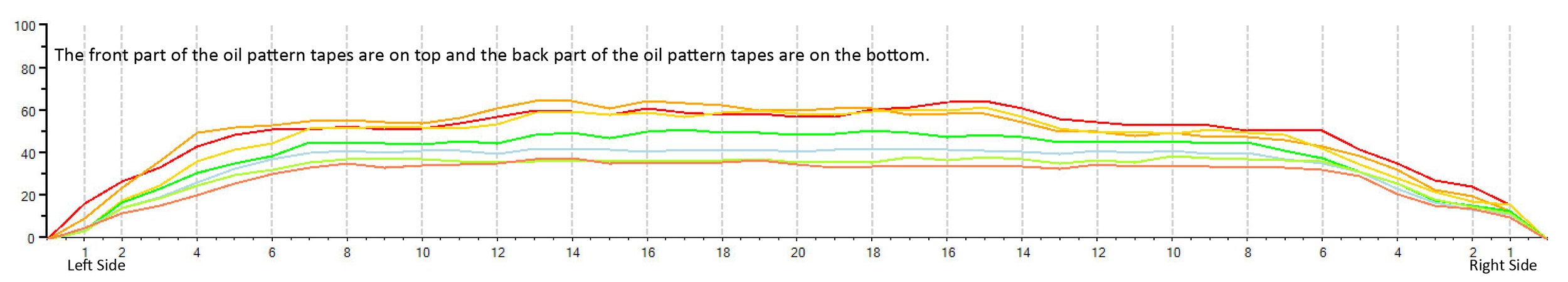

The final match was played on the WTBA Mexico City oil pattern which is fairly flat and 45' in length. Our after bowling tapes showed the optimum breakpoint was around the 10-11-12 boards on that oil pattern at this championship.

The ball tracks of the left-handers and right-handers during the trios championship match are on top of the LaneMap™ Slope Graphs.

Sir Isaac Newton, the father of gravity, was not surprised with the ball motion of the players during this match - Newton has known for a long time that gravity has the same influence on the bowling ball as friction, or lack thereof.

The green areas on the LaneMap™ have very little gravitational influences on the bowling ball. The light blue and orange areas are significant gravitational influences on the bowling towards the direction of the arrows. The red and dark blue areas are severe gravitational influences on the bowling ball towards the direction of the arrows.

Now watch the video below and see if you can see and understand what Sir Isaac Newton already knew. He has been whispering in our ear for many years that it's not always oil or lack of oil (friction), as the reason the bowling ball reacts differently from one lane to the next, or even in certain areas of the same lane.

Pay attention to the right lane and how many light hits the right-handed players have. Then look at the above Slope Graphs in the break point area. Those blue areas signify a significant slope to the right - which is why the ball has a hard time moving to the left. Slopes to the right beyond the oil pattern (for a right-hander) acts like "carrydown". But it's not carrydown causing those light hits - it's gravity,

Water Walker

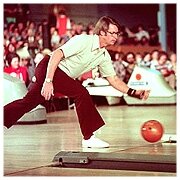

I think that in order to give this story as much credibility as possible, I am going to have to brag a little. I have been involved in doing the lanes with the PBA for over 800 tournaments, which included the National Tour, the Senior Tour and all seven Regions of the Regional Program. I am the only person who has done lanes for every bowler that is in the PBA Hall of Fame. In other words, I have seen them all. And, perhaps, I am really the only person who knows exactly what they bowled "on", as far as lane conditions go.

My personal All-Time Top-10, includes; Dick 'Water Walker' Ritger. You talk about TALENT. Dick was unbelievable. He was a world-class bowler, a world class guy, and later became a world-class coach. Without question he was one of the coolest, smartest, shot-makers in the history of our great sport. He could bowl on anything.

I have literally hundreds of stories of some of the tremendous feats that were performed by the greatest bowlers in the world; those that are in the PBA Hall of Fame.

This particular story took place in the early 70's. We (the Tour) were at Cranston Bowl in Cranston, Rhode Island. The weather was absolutely miserable as it had been snowing for about a week before we got there. It was 10-degrees outside when I got off the plane. Not only that, but my job as laneman was going to be a lot tougher this week because we knew in advance that the place was in bad condition because they hadn't resurfaced in a couple of years and all of the league bowlers had been complaining. And it was an old, drafty two-sided house and each side played drastically different from each other - as well as each pair playing differently from each other. I knew that I was going to hear about that.

After the first day of qualifying, Ritger was in the lead, which wasn't unusual for this 20-time champion (at the time). Almost every bowler was upset with the lanes and I had to hear about it.

That night at 2:00am I went in to do the lanes and it was now 19-below zero. There was so much snow in the motel parking lot, that and I couldn't find my car and had to walk about a mile to get to the bowl. About 15-minutes after getting there, part of the roof on the high-side (the real tough side) caved-in from the weight of the snow. It was a disaster. The janitor called the head mechanic who in turn called the Manager. He called everybody he knew to get in there to help clean up the mess. I called Harry Golden (the Tournament Director) to let him know what had happened. I cleaned and oiled the low-side then went over to take a look at what was going on over on the disaster side. There were about 20 people cleaning the water, snow, ceiling tiles and other debris off of the lanes and approaches. You could see the sky through the hole in the ceiling. I remember thinking: "I'm sure that the guys will blame me for this, too."

There were buckets on the lanes that were still catching water from the drippy roof. It was now 6:00am and the Pro's were scheduled to bowl at 9:00am. At that point I thought that there was no way. I started cleaning and oiling the part of that side that wasn't under water. When I got to the part of the house that had caved in, a "Miracle" happened. It had stopped raining and the dripping over the lanes had stopped. I cleaned and oiled the rest of the lanes. There were still some drips coming down over the lanes, but "Miracle number 2" was that the drips were only over the gutter gaps and the buckets that were placed there were catching all of the drops. It was about 8:45am now, and I took the lane machine to the back. The mechanic and all his helpers were back there huddled next to a little heater he had, and they were all trying to dry out.

When I came out of the backend, I saw about 20-bowlers standing in the settee on 31 and 32. I went over there to see what was going on. The only drips that were still coming down were over the approach on that pair and because of the full field, they had to use that pair in the tournament. Harry made the decision to leave the three buckets where they were on the approach. It was either that, or put 5 on a pair, and none of the bowlers wanted that. The buckets were to stay in place for BOTH squads.

I stayed around to watch the 1st squad bowl. After they bowled their 6-games that morning, the high game on the pair was 149. It was impossible for the players to walk around the buckets that were there to execute any type of normal shot.

Now the next squad came in to bowl. Ritger was scheduled to bowl his 2nd game on 31 and 32. It would be interesting to see what he could do there and not lose too much of the lead that he had enjoyed. When he got there for game 2 of this second day, there was a huge crowd in the bleachers, and standing behind the bleachers, as well.

I watched him (with no practice balls) alter his approach by snaking his footwork around the three buckets in a serpentine manner. I couldn't believe my eyes. He shot 279 like it was nothing. It was ridiculous.

One World - One Game

It has been almost ten years since John Davis (Founder of the Kegel Company), called together a group of experienced lane men in an attempt to further research the on-going lane conditioning problems with our Sport. It had become apparent that too many tournaments were deemed unfair by the participants and tournament organizers. Bowling ball technology had rapidly advanced and it was getting next to impossible for the lane man to do the job without some sort of social controversy. After that five day meeting in Sebring, Florida, Davis promised to undertake the huge task of taking care of lanes at every major tournament in the world and then posting those results on The Foundation website for the whole world to see. Davis and The Foundation came up with their initial slogan which was: “One World – One Game.”

The Foundation also coined two other phrases:

1. "You don't need to be a lane man to know that there are problems, you just need to be a lane man to know how bad the problems are."

2. "If not us, who? If not now, when?"

Early on, a series of scratch tournaments were developed, called: The Foundation Games. These events were held in this country (and abroad) with some promising results. They were unique by featuring ‘multiple conditions’ in an attempt to further challenge the participants by having more than one lane condition to compete on. Challenging oil patterns were used (both long and short) that required the athletes to compete on different lengths of oil during competition.

In 2000, Dr. P.S. Nathan, then President of the World Tenpin Bowling Association (WTBA), held a World Bowling Seminar in Malaysia and Davis was invited to attend along with many other bowling leaders from around the world. At that week-long educational meeting, it was unanimously decided that in order to find out who the best players were at any given event, the athletes needed to be challenged with these ‘multiple condition’ type tournaments.

The WTBA then formed a Technical Committee (TC) to continue researching the problems on a world wide basis. Since then, different tournament formats have been tested along with bowling ball restrictions (amount of balls used in the events) which were instituted. It is quite clear today, that some of the underdeveloped countries are at a disadvantage regarding bowling equipment.

For many years now, numerous thoughts, opinions and feelings about lane conditioning have been constantly expressed on most every bowling websites discussion groups. Depending on the average person’s position (agenda), most blame the problems with our game on various aspects of the game, including; pins, oil patterns, balls, kick-backs, flat gutters and an assortment of other things. Most have never done lanes and have no idea what that particular job entails.

Today, even with the use of different formats and multiple conditions, problems still exist in our great sport. The WTBA Technical Committee feels that it is time to try a different approach.

"One World - One Game - One Ball"

In 2003, Davis was named as Chairman of the WTBA TC, and Kegel was still taking care of all the tournaments for the WTBA and developing countless oil patterns. It became obvious that the lane man still could not do his job without some social unrest. Something else was needed.

The WTBA TC decided to research and test a type of bowling ball that would not mutate the oil patterns as much as today’s High Tech balls do. Davis was put in charge of doing the research for this project. Days, weeks and months went into this very technical testing, using CATS data.

A ‘prototype’ bowling ball was developed which showed encouraging results. During the week of April 17-22, a Bowling Writers meeting was scheduled in Orlando, Florida (which is only about 80 miles from Kegel’s Training Center), that was combined with the USBC Annual Meeting.

The WTBA TC also scheduled a meeting at this time and this was a chance to announce this new theory. A small scratch tournament would be held and the results would be shown to the world. Many top players from Florida would participate along with some other top amateurs and former PBA Tour champions. It was an eight game event that was bowled across eight lanes. The amount of oil that was used was 7.140 mL, which is an amount that was used in the early 1970’s.

Those results (total pin fall) were:

1. Bob Learn, Jr. (1880)

2. Vernon Peterson (1770)

3. Matt Gilman (1715)

4. Bob Handley (1675)

5. Mike Purdy (1671)

6. Larry Barwick (1670)

7. Rob Comito (1666)

8. Steve Johnson (1660)

9. Neil Stremmel (1655)

10. Storm DeVincent (1627)

10. (T) Sami Luoto (1627)

12. Chris Chartrand (1612)

13. Dennis Davis (1598)

14. Craig Auerbach (1596)

15. Saul Insignares (1573)

16. Tony Lavance (1572)

17. Ron Dixon (1523)

18. Jose Rodriquez (1514)

19. John Forst (1513)

20. Dennis Psaropoulos (1512)

21.Tony Crews (1477)

22. Bill Blackwell (1454)

23. Pekka Korpi (1383)

24. Josh Moore (1354)

Each player paid a $100.00 entry fee to enter the tournament, and that included a bowling ball. Each player had a choice of 15 or 16 pounds to use. Except for that weight difference, all of the balls were made as similarly as humanly possible. Davis donated an additional $2600.00 for a total Prize Fund of: $5000.00. Learn earned $2000.00 for the win along with a very nice banner that was signed by all of the participants and those on the WTBA TC. In all, 12 players cashed.

When asked if he wanted the banner, Learn said, “Certainly. It will go in my trophy room with all of my other cherished awards.” He added, “This was great. ALL tournaments should be like this one because I really think that it was the fairest tournament that I have ever bowled in.”

After the event, all the players were asked to fill out a detailed questionnaire that had a multitude of pertinent questions regarding the tournament. Those queries are currently being analyzed.

All in all, it was deemed a tremendous success by the Players and Officials. All results of the CATS data (from every shot, from every player) are also being analyzed. When completed, a detailed report will be sent to WTBA President Heikke Sarso for review.

STAY TUNED!

The Beginning

The year was: 1956.

The place was: Hillsdale High School in San Mateo California

My first recollection of Billy Hardwick was that of disbelief. What a sight it was. He was a sophomore, a year behind me in school. He was all of 5’3” and weighed-in at exactly 99-pounds.

He came out and (tried out) for the Varsity football team. The Head Coach, Frank Collins, looked at him and said that he was too small to play, but since we were a new school and needed players, he told Billy that he could hold the blocking-bags during practice. He also told him that because of his size (or lack of it) that he wouldn’t be able to issue him a team uniform.

But, Billy had guts and said that he still wanted to play and practice with the team. It was a cold and rainy day in September. There he was in his ragged, old sweat-shirt, sweat-pants and wearing his tennis shoes. The shoes were those old “high-top” canvas style and the laces were tied around the tops about 4-times. His skinny, little ankles were way too small to fill-up the tops of the shoes and it looked like he was walking around with two small “sacks-of-potatoes” hanging off of the bottoms of his legs.

The practice field was very wet and muddy that day, and the first chance I had to block him and the big blocking-bag that he was trying to hold-up, I put a little bit of an “extra” effort into it. The poor little kid had no chance. He went slipping and sprawling and sliding before eventually ending up on his back in the middle of a huge mud puddle. On his way down, all you could see were arms and legs going in every direction as he tried in vain to maintain his balance. It was an absolute riot. Even all of the Coaches were laughing.

I intentionally humiliated him once again when I reached down to help him up and purposely stepped on his foot with my football cleats. He let out a scream and rolled over (face first) in the mud. Now, he was covered from head-to-toe in the sloppy quagmire. It was hilarious. Everybody there was howling. Everybody that is, except for Billy. Looking back though, I was probably a big “bully” for doing that to him. Even though he never said it, I am sure that he hated me for doing that to him.

Basically that was the end of his football career. He did go on to play on the basketball, baseball and cross-country teams. Despite his slight stature, he was a fierce competitor. As the years went by, he would eventually prove “that” to everybody. His burning desire that he possessed soon became evident when a new bowling center opened in our town and he was finally able to find (and master), his sport.

During that year we became the best of friends, and that friendship has been a close one for 6-decades. I owe him a lot from what he has taught me and the countless doors that he has helped me to open. We have (personally) endured a lot together and I have countless stories about him. I will be telling some of them here……at least the ones that are suitable for print!!!

History tells us that he did go on the Tour, twice becoming Bowler of the Year. He was voted in the top 20-players of all-time and inducted into both the ABC and PBA Halls of Fame.

Today, Billy is alive and well and owns a very successful bowling center in Memphis, Tennessee. I still see him now and then and occasionally talk with him on the phone. If you see him, tell him that I said hello.

By the way, he did pay me back. Yeah, he was the rotten egg that got me into bowling!

Bowling Bedlam - Oil

The playing environment of bowling today may be as complex, unpredictable and chaotic as any time in the history of the game. We're not talking about the weekly league or club game where the participants just want to have fun. We're talking about professionally maintained and controlled tournament environments where bowling sports people compete.

It is in this type of sporting environment, along with the basic premise of playing well both physically and mentally, that the decisions the modem player makes will ultimately determine whether they perform up to their expectations or have to wait until the next event comes around.

This is the second in a series of articles that will try to shed some light on many of the variables in the current game of bowling and why the players of today need to be very open minded and aware of the total environment at all times when competing. The supplied information is all in the quest of understanding and to increase performance, not to create excuses.

Oil (Conditioner)

There are low viscosity oils and high viscosity oils. There are oils with different amounts of additives such as friction modifiers and flow agents for different types of lane machines. There are oils with varying surface tensions which help the oil bond to the lane surface.

Mineral oil is used in most lane conditioners as the base oil but over the years lane conditioner has evolved. Today's conditioners are now mixed with a percentage of specialized additives to increase the performance and durability of the conditioner.

All these different types of conditioners will make your bowling ball react differently on the lane. At the same time, different types of conditioner can make the same pattern play different.

If using a wick machine, some conditioners will flow through the wicks more than others making the same pattern settings apply a different pattern. With wick machines, temperature will affect the flow rate since temperature not only affects viscosity or the thickness of the conditioner, it will affect the size of the capillaries of the wicks as well.

If using spray type machinery, different conditioners will either peel off or hold onto the buffer brush more or less which can change the shape of any specific pattern even though the machine settings remain constant. Different lane surfaces will do the same thing so add that into the equation also.

There is a very good online article by Kegel's Chris Chartrand on lane conditioner (oil), "10 Things That Everyone Should Know about Lane Conditioners" which you can view by clicking on the title. Therefore we won't go into specific details on all conditioner properties but one thing we will touch base on is viscosity since the USBC has just made a new specification on this lane conditioner property.

The new viscosity rule the USBC has implemented "requires that lane conditioners used during USBC competition read between 12 and 81 centipoises at 70 degrees Fahrenheit." Centipoise (cps) is the standard unit of measurement for fluids and many lane oil manufactures will have this designated on their product.

Viscosity is very misunderstood in common bowling discussions. Most bowlers believe the higher the viscosity of oil, the "slicker" the bowling ball reacts to it. Actually the exact opposite happens.

By definition, viscosity is the measurement of internal friction of a fluid. The greater the amount of friction, the more force is required to move the fluid against itself which is called shear. Therefore the higher the viscosity, the more force it takes which increases friction. The lower the viscosity of oil, the less force it takes to shear which decreases friction.

In terms of a bowling ball rolling through these different oils, the higher the viscosity, the more resistance there is which makes the ball slow down more. When we get to the bowling ball portion of the series, we will spend more time on this subject but in short, friction is what makes the ball slow down and therefore enables it to hook.

Temperature is one of the biggest environmental factors in changing viscosity of a conditioner. So as the weather changes, so can the bowling conditions.

So what is the purpose of viscosity in lane oils? In short to provide durability to an oil pattern however, because of the many different additives being used in today's oils, viscosity is not as important as it once was in regard to lane maintenance. But as a bowler, you should be aware of how it relates to ball motion.

Oil Patterns

This subject of oil patterns is a difficult one and probably the most blamed and misunderstood subject in bowling. Lane conditioning rules have changed many times over the years and even today with the USBC 'three unit rule' or the USBC Sport Bowling rule in place, there are an infinite number of pattern combinations and ways to apply an oil pattern to the lane.

Kegel's Founder and CEO John Davis had a saying when he was entrusted in doing lanes over the years which goes something like this;

"Its 4 o'clock in the morning and the tournament starts at 8:00. You know if you do this; this might happen. But if you do something else, that might happen. So what are you going to do? Who do you call? Who can you call? You have to do something but there is no book. It is all up to you."

In these simple questions lies the major dilemma for every laneman at every bowling tournament in the world. Only after the tournament do they ever know if the job was socially acceptable or unacceptable. In simpler words, did the laneman do a good job or a bad job?

Of course the laneman might ask the same question to the bowlers; when trying to figure out the conditions, did the bowlers do a good job or a bad job?

2008 EYC - When Everything Comes Together

The 2008 ETBF European Youth Championships at famed Tali Bowl in Helsinki Finland showed what can happen in the modern bowling environment when all parts of the scoring environment are predictable and at a high level. During the Championships, 12 of 15 girls scoring records were broken and 11 of 15 boys scoring records were broken. There were also five 300 games during the Championships. However, the closer you look and dissect the possible reasons why those records were broken and scores were achieved, the less anyone should be surprised.

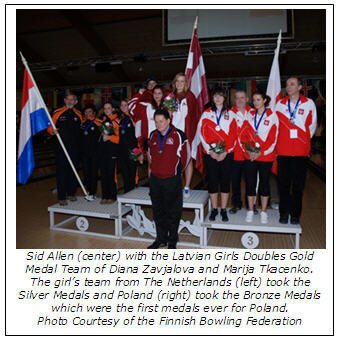

The Players

The youth players of Europe are more knowledgeable than ever and the overall level of coaching is at an all time high. Add to the fact that eastern European countries are increasing in participation numbers and they are treating bowling as a sport. Even world renowned coach Sid Allen has been attracted to Europe being hired as head coach of Latvia. This proved to be a great move on the Latvian Federations part as it helped them achieve the country’s first Gold Medals in Major Championship events. In fact Latvia won a total of five medals during the Championships, 1-Gold, 3-Silver and 1-Bronze. A fine testament to what a solid coaching program can bring to a Federation.

The Scandinavian countries have long been setting the standard in Europe by developing great player after great player. The Finns, Swedes, Norwegians and Danes all took medals in the boys divisions and from watching the youth competition at the 2008 EYC, the Scandinavian’s still are generating many great players.

But there are also some very good up and coming youth players from other parts of Europe because of solid coaching programs and Federation support. We should look forward to watching them in future European Championships and tournaments like the European Bowling Tour for many years to come.

Another item coming into place within Europe is increased equipment knowledge which is a huge part of being successful in the modern game. Until now and mostly because of language barriers, Europe as a whole has been behind the learning curve of countries where English is spoken or understood in high numbers. That however is changing and they are catching up fast as was evident by observing ball choices at this event.

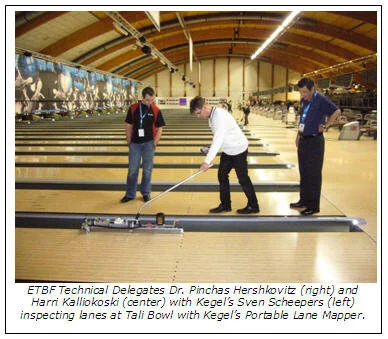

The Lanes

But back to the environment, the scoring or playing environment that is. Tali Bowl is somewhat of an anomaly in the world of bowling. Built in 1972, the Finns might have known something very few knew, or at least practiced, about the installation of bowling lanes. Even after the replacement of the wood lanes to Pro Anvilane synthetic panels, all lanes at Tali Bowl consistently have a certain topographical characteristic and the key word here is “consistently.”

Many of the synthetic lanes we have checked over the years have showed very little regularity with regard to topography throughout any specific lane but not Tali Bowl, all lanes follow the same topographical features throughout the entire lane surface. When lanes are installed in as a consistent manner as they are at Tali Bowl, players have to adjust very little as they move across the center during any one block of bowling.

As Team Norway Coach Trond Syvertsen said, “Only thing we did, was not to move too much and keep the ball rolling forward.”

Just imagine not having to take one, two or even three frames to figure out how the next pair of lanes is playing in relation to the last pair and only having to concentrate on releasing the ball the same way. This adds a minimum of 10 pins to the scoring pace right off the bat.

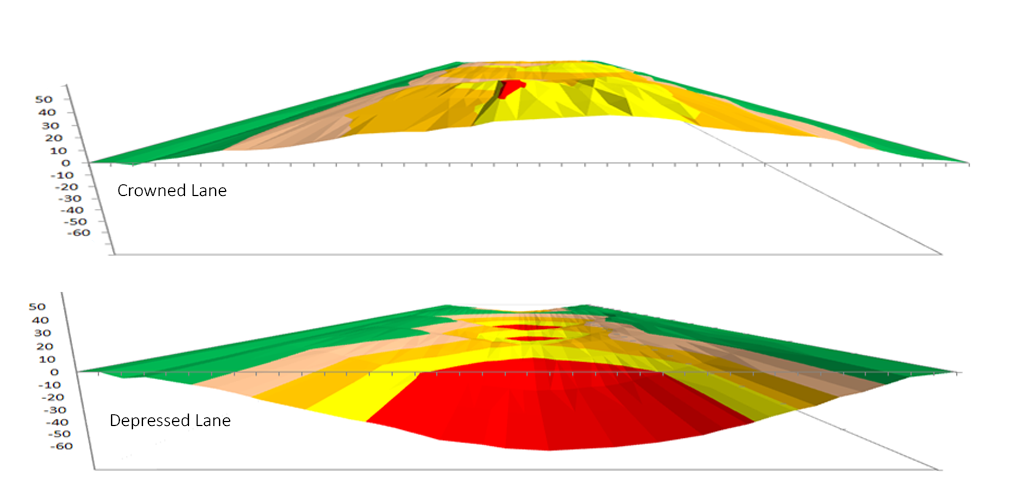

As far as the specific topographical character of the lanes at Tali Bowl, lanes can be crowned, flat or depressed. But because it has been requested by Tali Bowl representatives to not make certain aspects of the installation public, here is how different types of topography act to a bowling ball.

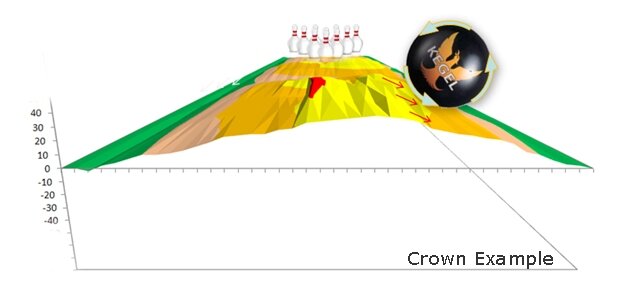

Crowned lanes act like a banked curve that is falling away from the apex of the turn. You won’t see race tracks built this way but we do see many lane surfaces that are installed this way.

As the bowling ball travels towards the channel, crowned lanes decrease the pressure between the ball and the lane which also decreases friction. This decreased friction of the bowling ball keeps the ball from slowing down at the normal rate and therefore also decreases the hook potential of the bowling ball.

Basically, on a lane that is crowned the bowling bowl is rolling down a hill as it travels towards the channel and then has to climb a hill as it makes it moves towards the pocket. This topographical property also decreases pin carry because it lowers the entry angle of the bowling ball into the pocket.

Crowned lanes are also more sensitive to release variations or ‘mis-hits’ which can cause inconsistent ball motions for the less repetitious player. For right handed players, the 2-10 spare combination is a common leave on lanes that are crowned.

Flat lanes, or lanes that are in the plus or minus 10/1000 of an inch range, are very rare in synthetic lanes of today but there are actually a couple documented examples. One is the Kegel Training Center in Florida. The other is the bowling center that held the USBC 5 person team scoring record of 3905, Chacko’s Bowl in Wilkes-Barre, Pennsylvania. That record was broken in 2004 but Chacko’s is still the host to the USBC Men’s three player team series record of 2443. Flat lanes provide the most predictable ball motion for the greatest variety of styles.

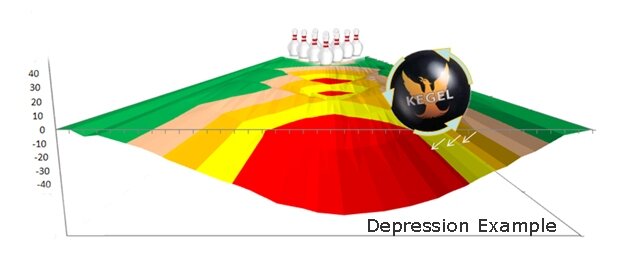

Depressed lanes act like a high banked curve at a race track. Just like a banked curve helps a race car turn easier, depressed lanes help the bowling ball curve back to the pocket easier.

As the ball travels towards the channel, depressed lanes increase the pressure between the ball and the lane which also increases friction. This increased friction of the bowling ball helps the ball slow down and therefore hook into the pocket with more regularity. This not only helps with consistent ball motion, it also helps with pin carry because it increases the entry angle of the bowling ball into the pocket.

And last but certainly not least is the lengthwise levelness of bowling lanes. Lanes that predominantly go downhill from foul line to pin deck make the bowling ball slow down less and therefore decrease hook potential. Lanes that predominantly go uphill from foul line to pin deck make the bowling ball slow down more and therefore increase hook potential. As in crowns and depressions, flat lanes are the most predictable for most styles.

An example of how lengthwise level affects ball motion is a bowling center Kegel checked during their lane maintenance years on the PBA Tour. In this particular bowling center, the high end always played significantly tighter than the low end which had lanes that were added on after the initial installation.

After mapping the entire center, the difference was found to be in the lengthwise levelness of the lanes. All lanes in the high end went downhill almost two inches from foul line to pin deck. The lanes on the low end were relatively flat.

As stated in the opening paragraph of this section, the most important thing about a bowling center installation is “consistency” in lane levelness from the first lane to the last lane. For the bowling player, this gives the most predictable ball motion from lane to lane and that equals the highest scoring potential. If there is one thing we can say about the bowling lanes at Tali Bowl, they have very consistent topographical features from lane to lane.

The Pin Carry

Tali Bowl has long been known for good pin carry. The pins used during the 2008 EYC were Brunswick Max’s but it was not the pins that made the difference, it was the lane installation plus the entire pit area at Tali Bowl. The side boards (kickbacks) are tight, the pin decks are solid and the pin spotting was good.

The last 300 game bowled in European Youth Championship history in the boys division was, you guessed it, at Tali Bowl in 1994. The first and only 300 game by a European girl was last year in Thessaloniki Greece at another consistent lane installation but that bowling center has since closed down.

The Oil Pattern

Ah yes, the oil pattern. The one thing everyone likes to focus on because it is invisible and therefore open to discussion, controversy, interpretation or whatever analytical word one can come up with.

Being a mixed youth event that employed a single condition, the main goal for the 2008 EYC lane maintenance team was to provide a playing environment where many different bowling styles had a chance to succeed. In order for that to happen, it was important to provide an oil condition that complimented the lane surface.

The pattern used for the 2008 EYC was 39 feet in length as announced in Bulletin II. Standard procedure in ETBF Championship events is to announce only the distance based upon the pre-tournament inspection which is normally six to nine months in advance.

At the 2008 EYC, oil pattern information was transparently provided to the teams like never before. As usual the teams were provided the lane machine settings, the forward volume, reverse volume and the total volume of conditioner. However this time they were also provided with the front-to-back taper ratios and side-to-side ratios.

For all ratio readings, USBC Sport Bowling calculations were used which averages the unit amount of conditioner from boards 18L to 18R divided by the average unit amount from boards 3 to 7. Currently, USBC Sport Bowling has the only official guideline for competitive oil patterns in bowling and states side-to-side ratios must be 3:1 or less. The WTBA and ETBF do not have definite oil pattern specifications so the goal for the 2008 EYC was to hit the high side of the USBC Sport Bowling ratio parameters.

The front-to-back taper ratios at the 2008 EYC were 2.2:1 on the inside and 2.7:1 on the outside portion of the lane. This means in the front part of the pattern there is 2.2 and 2.7 times the amount of conditioner in those zones compared to the amount at the end of the pattern. A 3D visual of the oil pattern was also provided.

Also shown to the coaches and players were the side-to-side ratios from six different tape readings. The pattern ratios at the 2008 EYC were 2.5:1 at 6 feet, 2.9:1 at 14 feet, 3.0:1 at 22, 27 and 32 feet and 3.2:1 at 37 feet using USBC Sport Bowling calculations.

In comparison, the side-to-side ratios of the 2008 EYC pattern were the same as the 2007 PBA Greater Detroit Open and PBA Spartanburg Open. In those PBA events, the ratio at the end of the pattern was also 3.2:1 but all PBA tournaments must pass USBC Sport Bowling standards. Therefore, the 2008 EYC pattern also passes USBC Sport Bowling and was on the same difficulty level as those PBA patterns.

Conclusion

Too many people think scoring pace is all about the oil pattern. Of course the oil pattern can make the scores higher or lower but so do many other abovementioned areas of the playing field.

However, should we not just have some specific oil pattern parameters and let the scores be what they are? Bowling should not penalize a good installation and reward a bad installation because of a perceived perfect scoring pace and until now, that is what bowling has been doing.

The play and competition during the 2008 European Youth Championships was fantastic. There are many very talented youth players in Europe right now and all the record breakers and medalists should be very proud of their accomplishments because they earned it.

I also hope the players realize how lucky they were to be able to compete in an arena like Helsinki Finland’s Tali Bowl. It is arguably one of, if not the best, bowling arena in Europe. And the ETBF European Youth record book proves it.

Bowling Bedlam - The Lane

The playing environment of bowling today may be as complex, unpredictable, and chaotic as any time in the history of the game. We’re not talking about the recreational league or club game where the participants just want to have fun, and the conditions are designed as such. We’re talking about professionally maintained and controlled tournament environments where bowling sports people compete.

It is in this type of sporting environment, along with the basic premise of playing well physically and mentally, that the decisions the modem player makes will ultimately determine whether they perform up to their expectations or have to wait until the next event comes around.

The players of today have to choose how to execute their delivery using which type of bowling ball, with which layout, with what surface preparation, on what lane surface, with what lane characteristic, on which oil pattern, and following what group of players. The player must also change this strategy rapidly and often during any specific round of play or throughout the course of an event.

This series of articles will try to shed some light on many of the variables in the current game of bowling and why the players of today need to be very open minded and aware of the total environment at all times when competing. The supplied information is all in the quest of understanding and to increase performance, not to create excuses.

The Lane

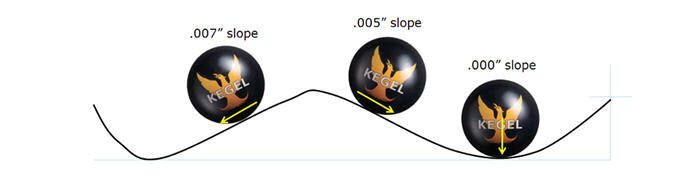

There is no question bowling balls of today are more frictional, hook more, and cover more area across the lane as it travels from the foul line to the pins. The modern core designs and coverstock compositions create more friction, which also makes the bowling ball more responsive to all the different variables that make up the playing environment.

There are different types of plastic film coated wood lanes which are the softest lane surfaces. There are wood lane surfaces coated different types of urethane which are the next hardest lane surfaces. The hardest and most common lane surfaces around the world now are synthetic lanes, with many different installation and friction characteristics.

We won’t get to deep into the specific manufactured hardness, friction, or wear properties of synthetic lanes, but keep in mind that all manufactured synthetic lane surfaces are different and how those surfaces wear from use is also not equal.

The USBC has performed studies that show some modern synthetic lane surfaces score best when brand new, some score better after a few years, peak, and then begin to score worse, while other surfaces score higher as wear and friction increases.

In regard to topography, the sanding techniques on wood lanes make those lanes much flatter than that of the installation of multiple synthetic panels. When a particular bowling center employed a strict resurfacing program, with skilled resurfacers, all the lanes in the bowling center was of high-quality and fairly consistent.

It is therefore a fair statement to say that wood lanes that are consistently resurfaced, screened, and re-coated on a consistent basis are more level than the synthetic bowling lanes of today.

One might think the contrary when only thinking about the synthetic panel itself. But when multiple panels are attached in sections on top of structures made up of other wood components, and more often than not on top of older wood foundations, it is easy to see the challenge for consistent levelness across a center using synthetic overlays. But it’s not impossible to achieve.

The current lane specification rules were written in 1937 by the American Bowling Congress, for wood lanes. The basics of the rule are the entire lane must be less level within plus or minus 40/1000 of an inch to be certified and approved for sanctioned play. The idea was that any groove deeper than the specification would allow too much guidance, or path correction, of the bowling ball after it was released by the bowler.

These level number limits also apply to crowns (hills), depressions (valleys), crosswise tilts, and lengthwise levelness. Surprisingly, only recently has the lengthwise level specification been added into the rules. The 40/1000 inch specification now reads “over 42 inches in any direction”, but only for new installations or centers that are changing from wood lane surfaces to synthetic overlays.

However, the overwhelmingly majority of the lanes are still inspected and passed by inspecting the lanes at only three predetermined points. These three inspection points are at a distance from the foul line between 10’-15’, 30’-40’ and 50’-55’. It is of course at these predetermined inspection areas installers of synthetic lanes pay most attention to.

Of course there are some very good installations and installers of synthetic lanes today but the reality is, installations are only as good as the time and care that is taken on a particular installation. Since the advent of synthetic lanes, achieving consistent levelness throughout a bowling center is a very difficult painstaking task and the tools and technology to level lanes in a more efficient manner have not been available. (Note: The recent invention of the Kegel Portable LaneMapper has made this process more efficient and attainable.)

Long time laneman and former PBA Lane Maintenance Director Len Nicholson states, “I’ve seen synthetics installed in 4-6-hours and they were legal according to the Sanctioning Body. This was in bowling centers that were changing over to synthetic overlays after their wood surfaces have reached their life limit. However, when the arena settings started on the PBA Tour and companies like AMF and Brunswick wanted to showcase their synthetic lanes, it would take them up to two days to get them as perfect as they could. And they were using their best installers performing the job on only four lanes!”

As the bowling ball travels down the synthetic lanes of today, it has to go slightly uphill sometimes, and then downhill at other times. The ball encounters random patterns of hills, valleys, and it encounters microscopic frictional differences, all without any uniformity.

By performing tests at the Kegel Training Center’s adjustable lanes in 1999 with top PBA professionals such as Parker Bohn III, Brian Voss and Jason Couch, it was proving that as little as 20/1000 of an inch, or 25 percent of the allowable tolerances, will affect the path and reaction of today’s highly responsive bowling balls.

These seemingly minute irregularities can cause a ball to increase its footprint which increases the friction between the ball and the lane. This will make the ball slow down more therefore increasing the hook potential. These topographical irregularities may also decrease the footprint between the ball and the lane which causes less friction. This makes the ball slow down less therefore decreasing the hook potential.

These random irregularities can make your intended shot possibly either hit the pocket heavy, light or in extreme cases even miss the pocket entirely.

When oil patterns that are designed to play more towards the outside portion of the lane are applied to bowling lanes which are predominantly crowned on the outside boards, it is difficult for the bowling ball to hook back into the pocket. Most short oil patterns are designed this way, and crowned lanes can make those patterns more difficult. However on longer oil patterns, or patterns designed to play more towards the inside portion of the lane, crowned lanes can sometime act like hold area which can increase mistake area.

On the other hand, bowling lanes that are depressed from the edge board can act like a race track with high banked turns on short oil patterns. The highest scoring lanes for short oil patterns are when lane topography is either slightly depressed or flat.

On long patterns however, depressions can take away hold area and make a long pattern more difficult since the ball will have a tendency to hook more. That is unless the player is on the other side of the depression. Then a depressed lane acts like that same banked race track a depression gives a player on a short pattern.

Unfortunately, rarely do synthetic lanes have a consistent character with regard to topography which makes it a challenge for both the players and the laneman.

For tournament players, depending on what lane a player begins their round on, these lane differences may determine a player’s equipment choice for the day or even where to play with no likeness of another. These choices can and often will cause the oil pattern to change in a different manner from day to day, squad to squad, pair to pair and even lane to lane.

A scenario often seen in leagues and tournaments throughout the world is when there are perceived differences in ball reaction, total blame is put on the oil condition when in fact most times it is the difference in the topography, surface friction of the lanes, or even the bowler themselves.

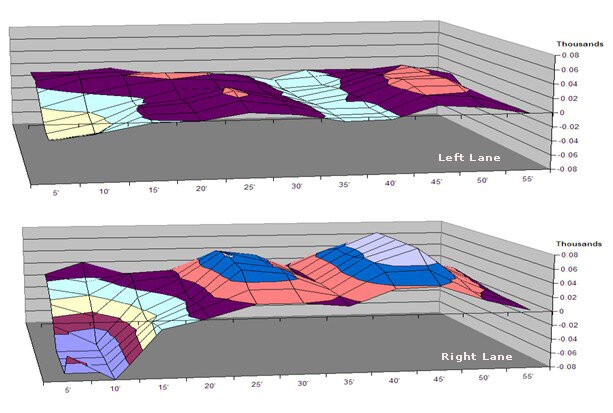

The below picture show a real world example of two lanes that make up a pair in a sanctioned bowling center.

The left lane of the pair is within specification, plus or minus 40/1000 inch, at most points throughout the lane. The right lane however has historically played notably different than its companion.

In this case, because of the extreme depression in the head area, and the excessive crowns in the mid lane and break point area of the lane, the right lane has always played considerably tighter. Basically the bowling ball is falling off the mountain in the midlane and then trying to climb the mountain as it begins it move towards the pocket. The depression in the head area also causes the ball to 'burn up' earlier which causes less back end movement. The players in this center say they are always lined up 4-5 boards different between these two lanes with the ball hooking much less on the right lane.

Take notice the points on the right lane that are within specification, which in this example are not many but only in the three aforementioned inspection areas. The left lane is also most level in those same three inspection areas.

Kegel has measured 1000’s of lanes and studied the scores of many different tournaments they have been associated with. They have found these topographical and frictional differences are the reason those “mystery pairs” tend to show up at bowling centers. It’s not always that those lanes or pairs are bad or out of specification and sometimes that one lane or those mystery pairs are actually flatter than all the other lanes. What makes them challenging is they are different than the others and players are trying to adjust to that one different lane off of all the others.

With all other things being equal, low scoring centers or tournaments are more about the lane surfaces throughout center being very irregular from lane to lane, while higher scoring can be more about the lane surface being very consistent from lane to lane.

In short, when centers have consistent topographical features from lane to lane, fewer adjustments from the players are needed.

Nicholson tells of an example from the PBA Tour at The Showboat in Las Vegas; “The TV Pair always played weird. The great PBA players always had problems. Scores on that pair were never up to par and eventually they changed the TV pair.”

If there is one thing you can take from this article, is to look at bowling lanes individually with each having their own unique characteristics. Don’t look upon a pair of lanes as both being the same or adjust to one lane in a pair off of the other lane unless you notice a specific trend in the center.

The balance between caring for the playing environment and it participants from the monetary pressures is one of bowling's sanctioning bodies’ greatest challenges. Our recreational fads will come and go with having to be continually reinvented to keep interest amongst those non-sporting customers. A healthy sport of bowling however will produce lifelong customers which every business person should want to create and sustain.

Topography: What does it all mean?

Topography - The Science of Representing the Features of a Given Surface.

Lane topography in today’s bowling environment is one of the most influential factors in ball reaction. In the past, when bowling balls did not grip the lane surface as much and therefore hook as much as today’s balls, lane topography was not as much of a factor. In short, the less the amount of overall hook, the less lane topography comes into play and the more the ball hooks, the more influence topography has on ball reaction.

The topography of a lane surface consists of three different types of measurements: Crosswise Tilt, Crowns & Depressions, and Lengthwise Level. Topography affects the ball reaction characteristics on each lane and is mostly responsible for those ever present "mystery lanes" you may encounter in a bowling center.

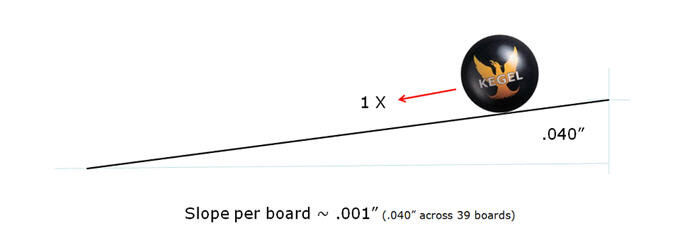

Crosswise Tilt

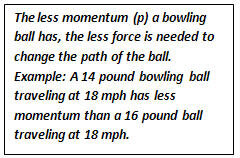

The United States Bowling Congress makes the rules covering lane specifications. All other Federations around the world follow the USBC in this regard. One such specification is the crosswise tilt, or the measurement from gutter to gutter which shows if one side of the lane is higher than the other side. The specification is plus or minus 40 thousandths (0.040) of an inch (1.106 mm). This is just over 1/32 of an inch.

The USBC provides special lane levels used in measuring and certifying bowling lanes. For crosswise tilt the level is laid across the lane, and the bubble of the level will move to the side that is high. Feeler gauges, ranging from 0.005 to 0.040 of an inch thick, are then placed under the low end of the lane level until the bubble is once again centered. The thickness of the gauges needed equals the amount of tilt on the lane.

The majority of lanes have some amount of tilt. While there may not be consistent tilt readings across all lanes in a particular center, there is often a degree of consistency on each lane, but not always. The amount the crosswise tilts affects the entire lane can be averaged between each arrow. Example: 0.040 thousandths tilt has an average value of 0.005 thousandths for every five board area.

The crosswise tilt becomes the greatest factor when the lane is tilted to one side for a certain length of the lane. The ball is more affected by the crosswise tilt from thirty feet to the pin deck as this is where the break point is or where the ball changes direction the most. It can have some impact in the front of the lane, but the tilt needs to be pretty large. (12-15-2009 edit: Recent testing and findings have changed this notion. Testing has found that the front part of the lane has as much, if not more, influence on ball motion and direction as any point throughtout the lane. In an area of less friction, less force is required to move an object off line. Newton's Laws of Motion)

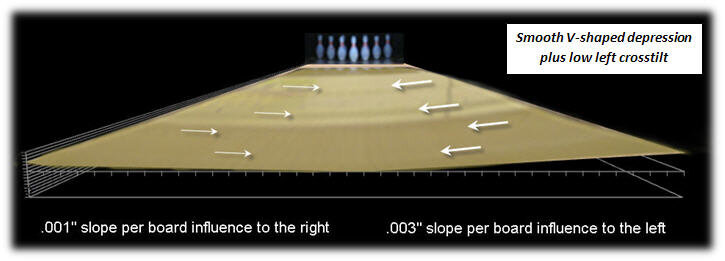

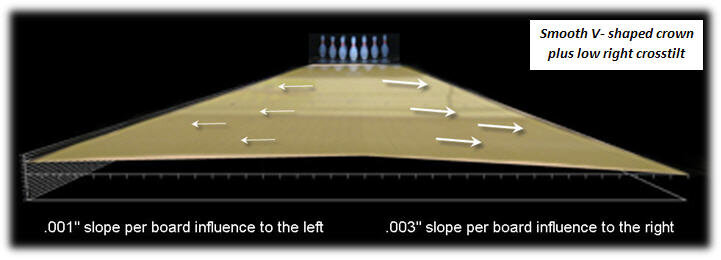

In simpler terms, if a round object is placed on a flat level surface and then one side is raised, the object roll towards the low side. Remember, this is only one of the pieces of lane surface characteristics. Below are examples of crosswise tilts:

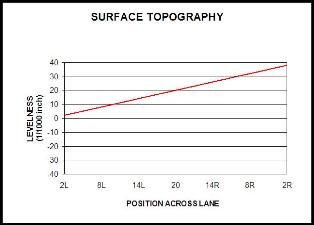

Crosswise Tilt - High Right

Crosswise Tilt - High Left

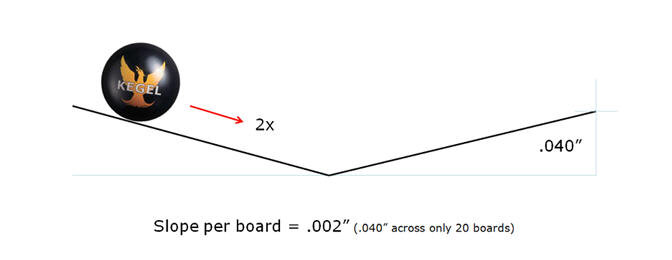

Crowns and Depressions

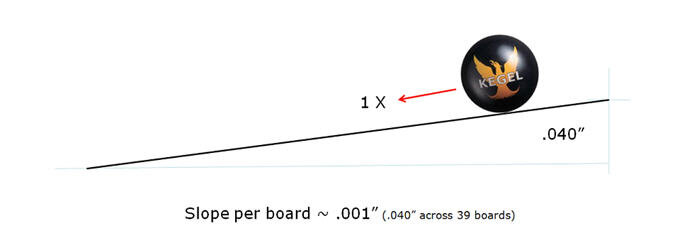

The crowns and depressions show the actual shape of the surface from gutter to gutter.

A crown is an increase in height from a given zero point. The peak of the crown, of course, is the highest point. The peak, however, is not necessarily the center of the lane. It can peak at any point across the lane. A crown, unlike crosswise tilt, is measured by the amount of change across each five-board area. This is also measured using the lane level with an attachment called the Dial Indicator. The indicator glides across the level reading the amount of rise or drop of the surface in thousandths of an inch. (12-15-2009 edit; with the invention fo the Kegel Lane Mapper, topography is now measured on each board instead across a five-board area.)

A crown can give the bowler a sense of hold but also takes away swing area. Like crosswise tilt, crowns have more influence when they remain consistent across a certain length of the lane. Crowns have a tendency to benefit players that do not cross a lot of boards. Two units of oil can feel like five units when the lane is crowned. The amount of pressure that the ball has against the lane is less when going away from the pocket but greater when more direct. It is like riding over a hill.

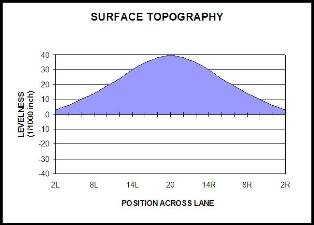

Example of a 0.040 inch Crown

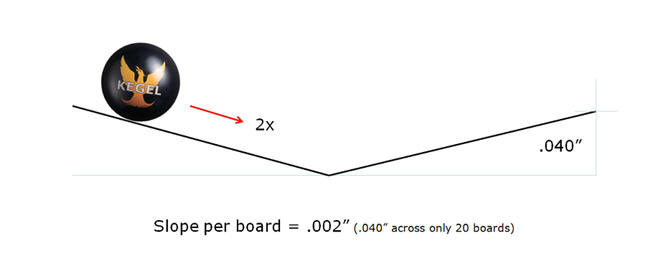

A depression is the opposite of a crown. The shape is measured by the amount of decrease from the zero point. This concave shape allows bowlers to feel that there is more swing area but less hold. It can make a line near the gutter have more swing area. Basically, five units of oil can react more like two units of oil.

A depression can also force players to cross an increase number of boards. The pressure the ball feels on a depression is greater when crossing boards which increases friction between the ball and the lane. But a ball thrown on a more direct trajectory will have trouble reaching its break point because of this increased friction.

A depressed lane is very much like a banked turn on a race track. When an automobile or motorcycle hits the banked curve, it becomes easier to turn and also slows easier. The momentum of the vehicle is now compressed into the embankment.

Example of a 0.040 inch Depression

The USBC specifications for crowns and depressions are the same as crosswise tilt, plus or minus 0.040 of an inch.

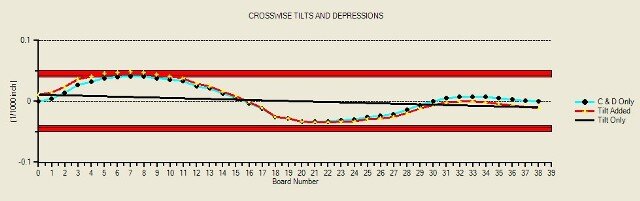

Crosswise Tilt + Crowns + Depressions readings at a distance of 42 feet from the foul line.

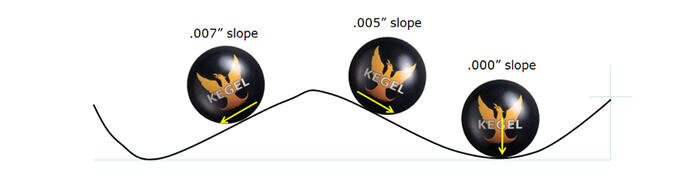

Lengthwise Level

The lengthwise level of the lane is the final piece in the topography puzzle. This can also have dramatic effects on ball reaction. This allows us to see how many hills and valleys the ball sees rolling down the lane. Like driving, the vehicle maintains or even increases speed when moving down a hill. It slows quite a bit when moving uphill. A lane that runs uphill or downhill from 30 feet to the pindeck will become more sensitive to speed changes. This is caused by the amount of surface pressure that the ball has against the lane. A lane going downhill can play tighter and an uphill lane can promote more hook.

Most lanes are installed using a carpenter’s string or a laser. One problem with a carpenters string is it will tend to show the lane is lower in the center than at the foul line and pin deck. In our data collection process we collect the lengthwise measurements every five feet, with a laser.

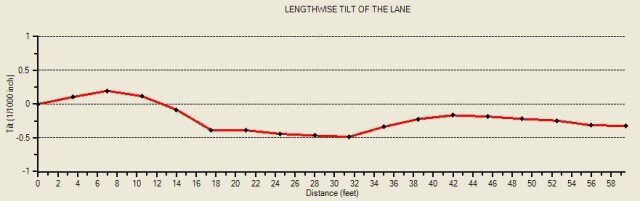

Example of a lane’s lengthwise level taken every 3.5 feet:

Three-in-One

When all three factors (crosswise tilt, crowns and depressions, and lengthwise level) are added together, many different things can happen. Each lane has some differences whether it is one or all of the three factors. Certain combinations of the three can have somewhat similar characteristics as a lane that has a different topography. Inequity can be seen in a surface and the level of a lane can give a certain style or side an advantage.

The patterns run for most high level competitive bowling events allow the topography to stand out. The patterns themselves normally do not provide much swing area or hold area, so we have an idea of what the reaction should look like. When we see something different, we could make the conclusion its the topography. It might also the way the players you are following are breaking down the oil pattern, but that is another discussion for another day.

Believe it or not, wood lanes tend to be the most consistent across a given center. The reason is the sanding equipment does not allow for significant changes from lane to lane. Most lane resurfacing machines have a fixed pattern for making cuts during the resurfacing process. But keep in mind, there can still be mystery lanes.

On the other hand, most would think synthetic lanes are the flattest surface currently on the market, but that is far from the truth. Lanes made up of multiple synthetic panels can, and are the majority of the time, be vastly different from lane to lane across a house. There are many reasons for these inconsistencies with synthetic lanes.

Reason #1: The Weather

Centers located in areas of the world that can experience large temperature and humidity changes from season to season, see the most changes in topography (both wood and synthetic). Even though the lanes are synthetic, they are still made of wood in one form or another. Substructures are made of a pressed board, and pressed fiberboard's (wood fibers). The actual surface is made up of sheets of pressed paper with a melamine layer that the ball touches. So the surface can absorb moisture from the air and it can dry out when the air is dry. All wood does this!

Reason #2: The Installation

How synthetic lanes are installed is very important. They may initially be consistent across the house. Eventually the lane takes abuse and gets exposed to environmental factors, explained above. Remember that a wood lane is one solid piece while the synthetics are separate pieces screwed together. An installer may tighten screws tight enough to dimple the surface and cause the areas not screwed down to "bubble" up.

All of these factors make up the topography of a particular lane surface which can and probably will influence the reaction of your bowling ball.

Changing Lanes

With the invention of the Kegel LaneMapper, came a study about bowling lane topography like no other in the history of the game. Truth be told, when lanes were made of wood, and resurfaced in a timely manner and taken care of by craftsmen, topography was not really an issue. But with the proliferation of synthetic lanes and overlays, along with lanes getting minimal attention today, topography is much different and more influential than in past times – and the Kegel LaneMapper has been able to show it.

We now know what lanes shapes favor different type ball rolls. We know exactly why the same oil pattern can play completely different from one center to another. We know that different lane shapes can affect the durability of an oil pattern, or lane conditioner. And we know that different types of lane constructions are not created equal, nor do they change equally. It’s within this last statement this edition of the Inside Line will focus on – how synthetic panels laid on top of wood lanes can change with seasonal changes.

“All lanes look flat, but they really aren’t.”

We’ve always known that wood lanes change from summer to winter. In the days of regularly resurfaced and maintained wood lanes, we saw depressions go from the minus .010” range to maybe the minus .020” to .030” range in the winter months – a depression increase of 10 to 20 thousands of an inch. In climates where seasonal changes and humidity differences were greater, so were the changes in the lanes.

But today, because of the aforementioned lack of attention lanes receive, we are seeing changes much greater from season to season - especially in climates that have greater seasonal differences.

A big part of Kegel's original Mission Statement was “we study the game of bowling”. It was a mandate from the late John Davis. This edition of the Inside Line will focus on some of that study from bowling centers around the world, and we will show how much, and how fast, bowling lanes with synthetic overlays can change in shape.

Real World

Our first example is from a bowling center located in the northern hemisphere. Being in the north, there can be significant differences in humidity from summer to winter - it is humidity that makes wood change in shape.

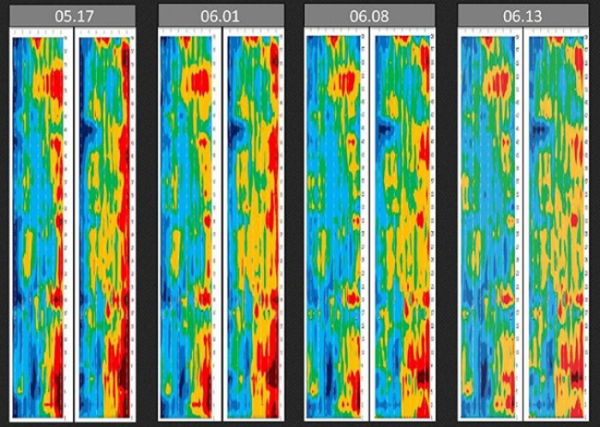

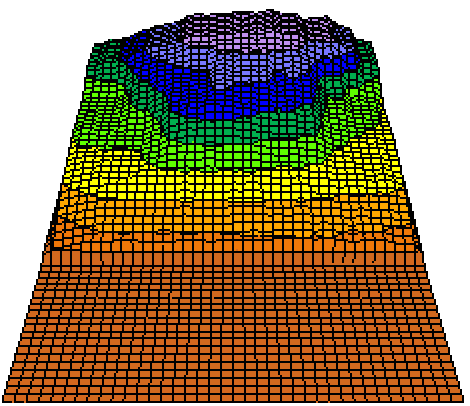

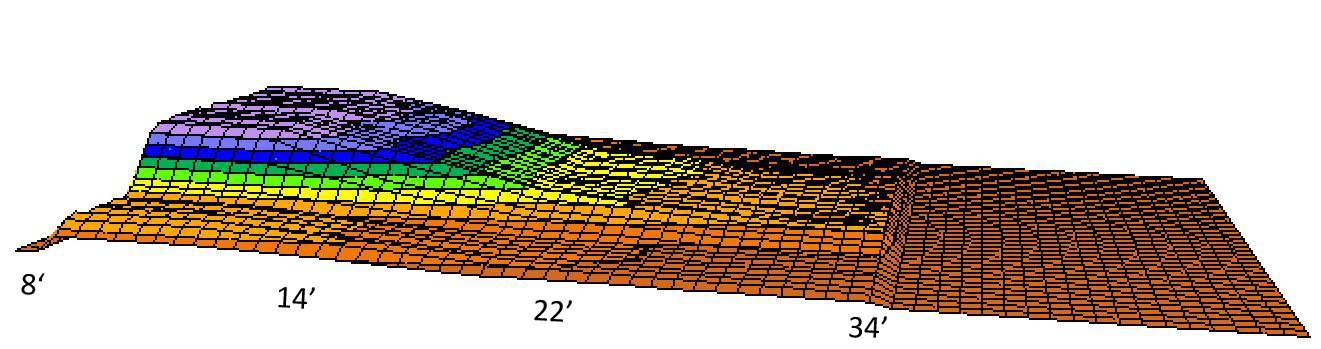

The graphic below is a lane with a synthetic panel on top of existing wood lane (overlay) in the summer time when the humidity is highest. Humidity always enters wood in the area of least resistance and with a wood lane humidity enters the wood from the bottom of the lane.

Synthetic overlay measured in August when humidity is high.

We call this a ‘bird wing’ shaped lane because the wood lane pushes the panel up between the screw rows (2L, 20C, and 2R boards) causing a hill around the 10 board. This lane shape will cause hang spots outside of second arrow, and “hook” inside of second arrow. Medium length patterns are most difficult on this lane shape.

The wood lane underneath the synthetic panel "pushes up" the panel between the screw rows causing the shape of the lane to resemble a bird wing.

What is also interesting is the lanes in this center pass the plus/minus .040” specification at every distance on the lane, in the summer time.

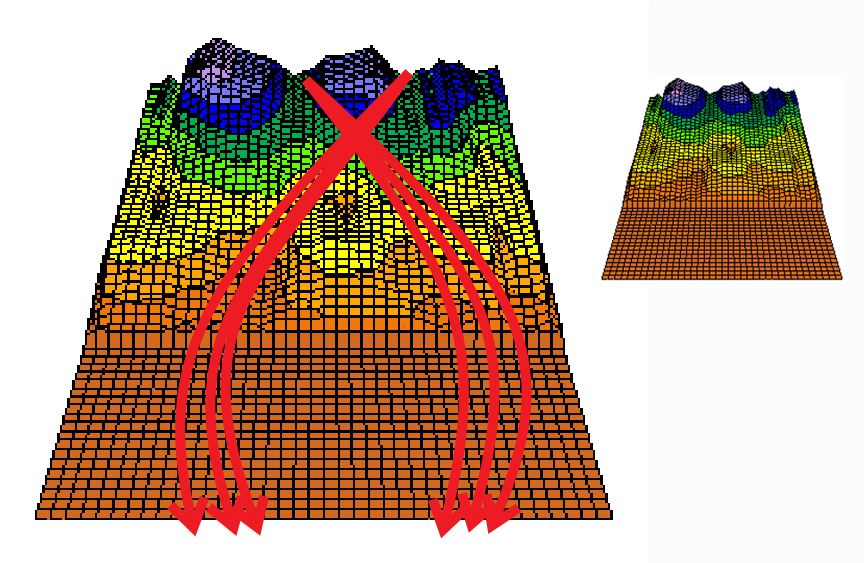

The below graphic shows what the lane looks like during the transition from summer to winter, or winter to summer. In the fall time, the humidity has decreased causing the moisture in the wood lane to also decrease - everything is contracting and the panel takes shape of what’s underneath it. In the spring time the process is reversed. Medium oil patterns begin to play easier - actually all oil patterns begin to play easier.

As the humidity begins to lower, the moisture in the wood lane begins to release, making the wood lane contract. Measurements taken in early November.

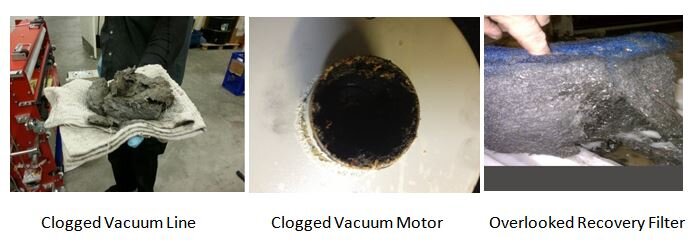

Where the lane gets the most abuse, the head area, the depressions begin to exceed the minus .040” specification. The toe screws holding the wood lane together, and the screws that hold the wood lane to the levelers below, are getting loose, or back out all together in many instances. The lane acts like an accordion.

It must be noted that when the heads are cut out and replaced with a substrate like MDF, we do not see these huge depressions. Synthetic panels on top of a substrate like MDF, HDF, or PSL, do not seem to be affected near as much during seasonal changes.

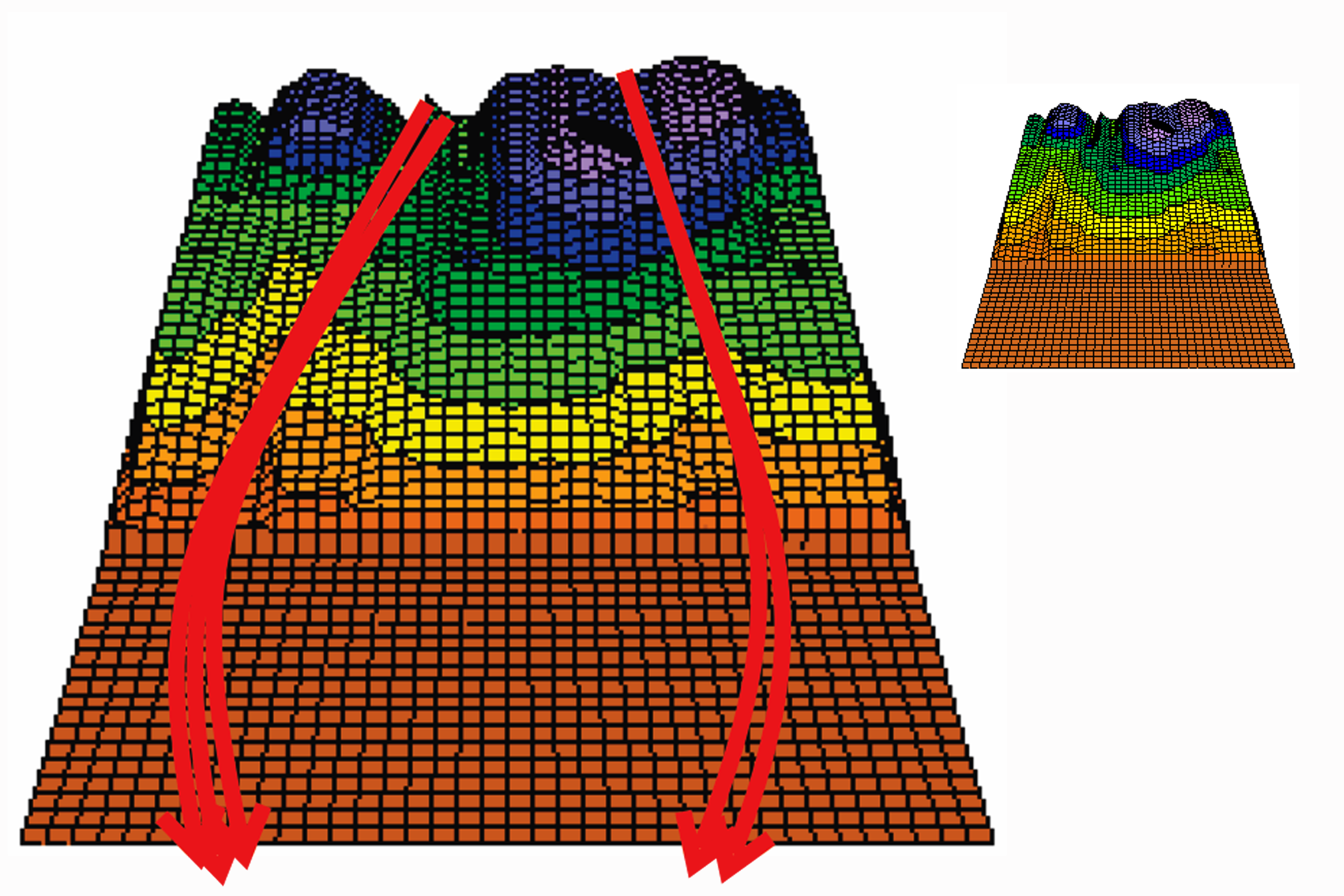

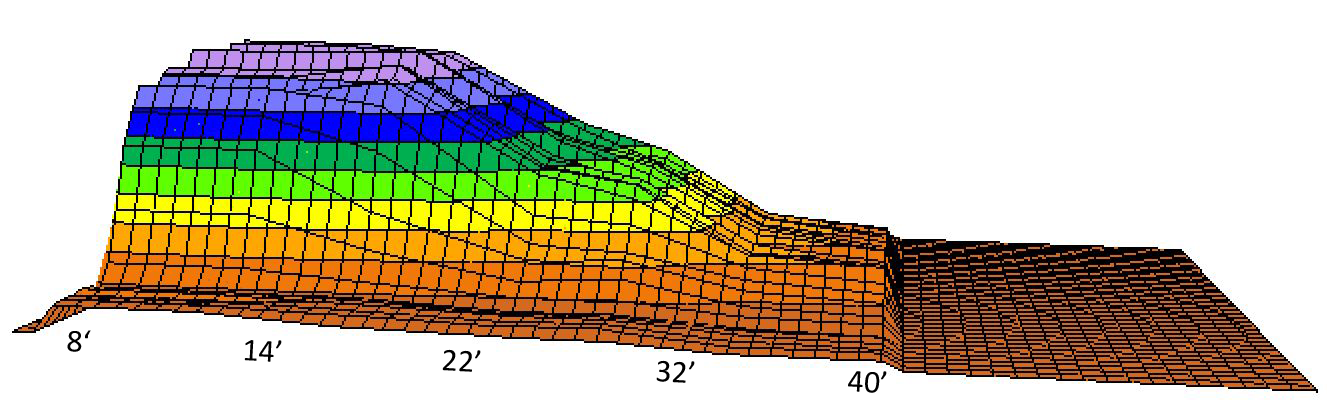

Below is what the above lane looks like in the winter time, when the humidity is lowest. In some instances, bowling centers may even turn the heat on, which lowers humidity even more. It's at this point in the year most of the moisture has come out of the wood lane and the depressions are the greatest. This is also when oil patterns tend to play the easiest; everything “ramps back” to the pocket.

When the humidity is the lowest, the depressions increase the most.

What may be thought provoking for some is, every distance on this lane has now exceeded the minus .040” specification. We have seen this in more than a few instances.

Oil patterns on a lane with depressions of this magnitude will also tend to break down quicker, when playing outside of center. This happens because there is more pressure (gravity) pushing up against the ball when outside of center so it's easier for the ball to "poke through" the oil film on the lane - the “shot” will tend to go inside quickly because of that. Think of a car rounding a curve on a banked road or race track - the banking is there to help a car navigate the turn.

This is when lofting the gutter often comes into play on competitive longer patterns - the ball will “see the lane quicker” as the pattern breaks down on the uphill slope. So players quickly move to and play the downhill side of the depression as long as they can. Physics dictates that the ball will retain energy longer on the downhill side of depression and then hook off of the uphill side easier. Once deep inside, bowlers with high rev rates, high axis rotations, and high tilts will benefit the most on this lane shape - that's physics at work also.

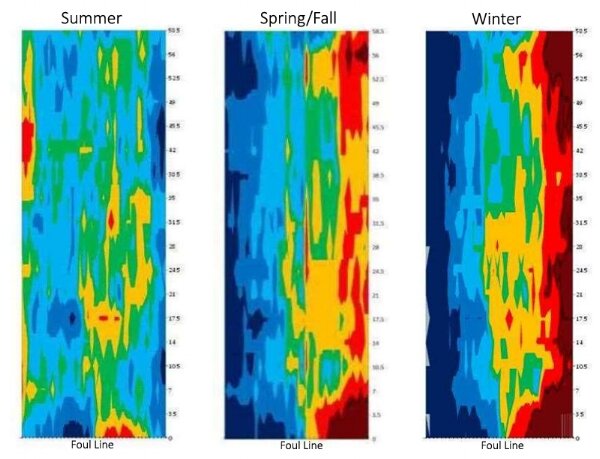

The Kegel Slope Graphs make the slope differences even more apparent:

Same lane over the coarse of seasonal changes.

The Slope Graphs are revolutionary in bowling because they are the first illustrations that show the severity of the ‘rise and falls’ on a bowling lane. Slopes to the right are in the blue color spectrum – the darker the color the more severe the slope to the right. Slopes to the left are in the orange/red spectrum - the darker the color the more severe the slope to the left. Read more about Kegel's Slope Graphs.

How fast can lanes change?

The following graphic shows how a synthetic overlay pair of lanes can change over the course of 28 days – from May 17th to June 13th. This center is also in the northern part of a country and one floor below ground level – so if anything changes are less than a center on the ground floor or above. The foul line is at the bottom of the graphic.

A pair of synthetic lanes with overlays changing during a 28 day period - from May to June. The foul line is at the bottom,

What to notice here are the slopes on the outside part of the lanes – reds on the right are slopes towards center and blues on the left are slope towards center - so the lanes here are predominantly depressed at the beginning of this time frame.

Over the course of 28 days it is clear that the depressions are decreasing. The reds become lighter in color so the movement towards center is less influential, and some areas of the lane are even turning to blue in color, which indicate slopes to the right. Hang spots are caused by these "outward slopes". What we noticed during these 28 days was "the oil pattern" became tougher as the lanes flattened out - gravity always wins on planet earth.

If we talk about the raw data, the lanes were changing (swelling up) about 6-7 thousands of an inch per week as it takes in moisture. In 28 days the depressions went from the mid-minus 30 thousands of an inch to less than 10 thousands of an inch. And the process will reverse itself come fall time as the wood releases all that moisture.

“Gravity always wins on planet earth.”

How this can help you – the proprietor, the bowler, the coach, the federation, or the tournament organizer.

With synthetic lanes it’s even more crucial to see these slopes because it’s the only way we can really understand what’s happening with ball motion – is it friction or a significant slope causing the ball to hook too much, or not enough?

Knowing the shape of the lane at different times of the year will tell you the answer, and it will also tell you how an oil pattern will play, develop, and breakdown.

For instance; when the wood underneath the synthetic swells up in the summer your pattern will play longer or it seems like carrydown comes out of nowhere – the ball has a hard time moving towards center, when the lane is sloped towards the gutter.

This lane swelling can also "make the shot" go more inside as bowlers stay away from the hang area towards the outsides.

This is especially important to any one bowling center when trying to provide lane conditions for their weekly league customer base. If your center has lanes that change as much as these examples, you may need different house patterns for different times of the year so the house playing characteristics stay more similar.

It’s also important to know if a bowling center wants to “experiment” with a different oil pattern or try a new chemical product. If you don't which way your lanes are changing, or how much, it will be difficult to know why things are playing the way they are.

It’s important for tournament organizers or federations to know so when they ask for a pattern months in advance they have a better idea of what to expect come tournament time. Testing an oil pattern in one part of the year and expecting things to play the same at another time of year will often make the question "what happened" arise.

It’s important for coaches and bowlers so they can properly prepare for an upcoming tournament, or make the proper adjustments when the bowling ball is not reacting like they think it should.

Technology can definitely make life easier when used in the proper manner – the Kegel LaneMapper is one of those advances.

When used it can definitely help a bowling center get know their lanes better and use oil patterns that compliment the predominant shape of those lanes to provide more consistent playing conditions for their customers.

Or better yet, the LaneMapper can tell you where and how to correct your lanes if needed so they are "fair" for as many styles as possible.

In a game like bowling, providing equal opportunity for as many different playing styles as possible should be the goal. It worked before and although history may not always repeat itself, it sure does rhyme.

The One Thing That Really Makes Oil Patterns Play Different

Normal force, N, is the force that pushes up against an object, perpendicular to the surface the object is on. In other words, the normal force is the force pushing the two surfaces together. The stronger the normal force, the stronger the force due to friction.

How often have you experienced an oil pattern that didn’t play anything like the pattern graph suggested it would? The pattern was ‘x’ length, the high point of the oil on ‘y’ board, yet when you played on it your ball didn’t react anything like you expected, and the optimum pattern exit point wasn’t near where it was “supposed to be”.

From there we look for explanations, and we might get answers like; “the temperature was different today”, “it was raining outside”, “the lane machine put out the wrong pattern”, or who knows what else. In past years technology might not have been available to check things, so theories flourished.

Today, however, we can use technology to confirm the correct pattern is in the lane machine. We can use the Lane Monitor to make sure it was applied correctly to the lane. And with the Kegel LaneMapper, we can even measure the topography of the lanes to see if and how that influenced things.

Knowing and understanding these critical components about our invisible playing environment can help us answer the infamous question every person entrusted with lane conditions has heard at least once in their life; “what happened?”

What lane topographies are most common?

The Kegel Training Center has 12 fully adjustable lanes that can be shaped to mimic almost any lane topography known to exist. After measuring thousands of lanes over the years we have shaped three pairs of lanes in the KTC with some common topographical shapes, and one pair of lanes we consider as “fairly neutral”.

Neutral lanes are not perfectly flat, no lane in the world is, but a neutral lane has topographical slopes on them which do not “overly disturb” the ball as it travels from the foul line to pin deck.

We see neutral lanes often when they are made of wood and resurfaced regularly – these lane types are the “flattest” lanes with regard to topographical shape.

We also see neutral synthetic lanes, but not very often. In fact, of all the synthetic lane bowling centers we have mapped over the years we can count the number of centers having totally neutral synthetic lanes on one hand – it's definitely the exception, not the rule.

The three most common topographical shaped lanes today are what we call a seagull-wing or bird-wing shape, depressed (dish-shaped), and crowned (mound-shaped). These lane shapes are where things get interesting with regard to oil patterns, how they play, and maybe most important, how they develop as the oil pattern breaks down.

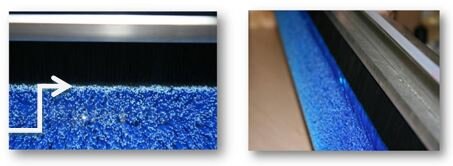

Seagull-wing shaped lanes have slopes towards the center from around the second arrow, and slopes towards the gutter outside of that. This happens because a synthetic panel is mostly screwed down on the outside 1st or 2nd boards on either side and then in the middle on the 20th board. In-between there are no securing screws “holding the panel down” other than where the panels meet, which is only every 10’ or 12’ depending on the manufacturer.

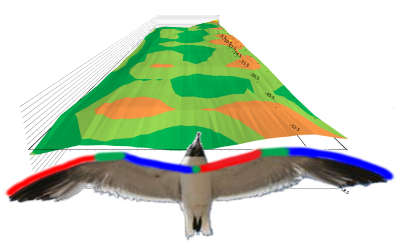

Seagull or Bird Wing Lane Shape

In the summertime when the humidity is high, or in climates with high humidity, we see this lane shape very often - especially when wood lanes are underneath the panels.

Moisture penetration on a wood lane comes from the bottom of the lane where the boards are put together essentially making the lane swell up, which then pushes up the panels in-between these rows of securing screws. This causes the lane to “mound up” around the 8-9-10 board creating slopes towards center inside of that area, and slopes towards the gutter outside of that. The resulting shape resembles a seagull's wing.

Furthermore, in both new lanes with a continuous LSL underlayment (Laminated Strand Lumber - an engineered wood product) and for certain manufacturers who use MDF or LSL to replace the old wood head section, there is a similar securing-screw pattern.

Just like the lane panels themselves, the underlayment is top-screwed in three spots across the lane, near the two outer edges and near the middle, at each of the 30 or so securing locations along the 60' length of the lane. This can also create a bird-wing shaped lane; albeit not as severe as what we see with a wood lane underlayment in high humid environments.

Crowned lanes also happen in year-round climates with high humidity; like Island countries, cities by the sea, or in Southeast Asia. This often happens with overlays where the wood lane underlayment was not screwed down in the middle prior to the lane panel installation.

Depressed lanes often happen in lower humidity climates, or in the winter time, with a wood lane underlayment. In fact, all wood lanes are cut with a slight depression in them, but the longer the panels have been on top of the old wood lane, the more they tend to depress - especially in the area of the lane that takes the constant pounding of the bowling ball, the first third of the lane.

Have you ever notice that scores often go up after Christmas time? This is when a wood lane, or synthetic panels on top of wood lanes, become most depressed because the moisture has finally been released from the wood causing it to contract (shrink). Think of a high banked race track - it's much easier to navigate the curve.

New synthetic lanes can also be installed with a depression, but rarely do we see a nice smooth depression like a resurfaced wood lane has.

Although we see these type lane shapes often down the entire lane, we also see at times a combination of shapes on any one lane. For certain type overlays, we often see very depressed heads and slightly beyond (mostly related to ball impacts), and then bird-wing shapes after that.

In the case of a new synthetic installation, we often see topography slopes that are totally random throughout any one lane, or even within one panel.

Lane shape is more the reason than anything else why certain styles (ball rolls) “match up” to certain bowling centers.

Because of the invention of the Kegel LaneMapper and resulting Slope Graphs, we now know why, and we can show it.

Where the rubber meets the road

A few months ago the Men’s National Team from Sweden came to the Kegel Training Center with a special request; to learn more about topography and train on lanes with topography differences. So to prepare for their visit we adjusted lanes 5-6 with a seagull-wing shape, lanes 7-8 with a crown, and lanes 9-10 with a depression. We also made sure the lanes remained within USBC specifications.

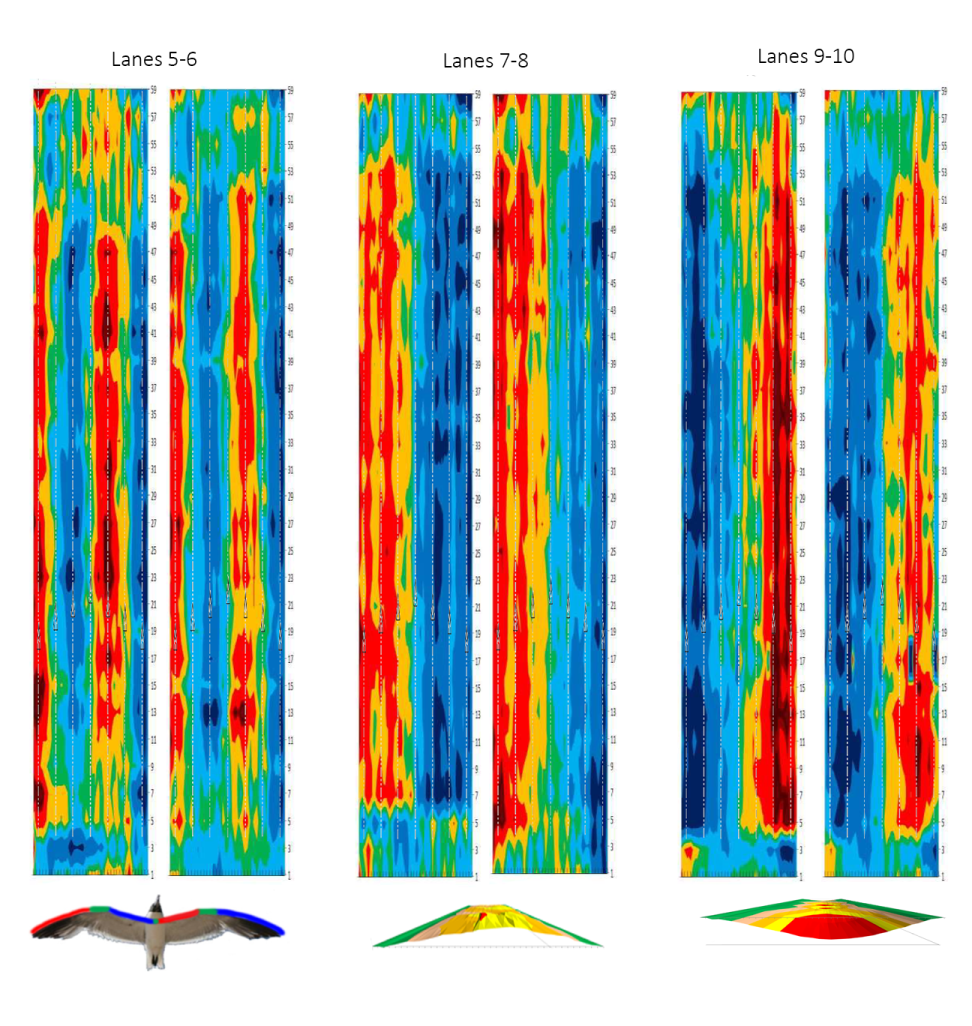

Below are the Slope Graphs of each pair of lanes:

Remember, the specification for lanes is plus/minus .040”, and it does not specify which way a lane must be shaped in order to satisfy those requirements. The specification also does not state over how many boards those min/max numbers can hit their limit, and that’s where things can get interesting.

For instance, if there is a .024” rise on the lane from the gutter to the eighth board, that’s an average Slope per Board of .003” – that equates to a smooth cross-tilt of .120”. The ball has a very hard time “hooking back to the pocket” on a slope this severe and we see this more often than you might think.

For more about Slope per Board, read this article: Kegel’s Revolutionary Slope Graphs.

So how does lane topography affect an oil pattern and the resulting breakdown?

This is where we have learned the same thing Sir Isaac Newton learned – you can’t fight gravity, you can only work with it.

For a little test and learning experience for all involved, we decided that the 12 players from Team Sweden would bowl six games across the three pair of lanes moving every game – this would make all players hit each pair twice.

There were three left-handed players and nine right-handed players. We chose a medium length oil pattern from the 2017 World Bowling patterns, Beijing.

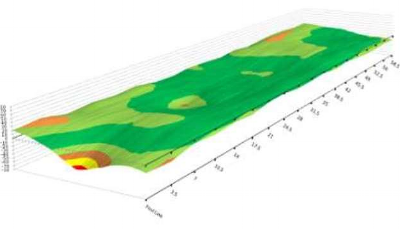

Here is what the fresh oil pattern looked like, with the foul line being at the top of the graphic:

2017 World Bowling Beijing oil pattern

After 12 games of bowling, we took after tapes on each of the pairs to see how the players broke down the oil pattern on these different lane shapes.

On lanes 5-6, the bird-wing shaped lane, players tried to play outside in practice but the slopes towards the gutter made it play very difficult - they immediately “moved inside” and away from the “hang spot”.

Beijing oil pattern breakdown on the bird-wing shaped lanes

The after tapes show the paths of all balls by way of oil pattern depletion. From these tapes, we can clearly see both left-handers and right-handers played deep inside on this pair of lanes. Our tape data also shows the farthest outside anyone got was on board 9, because there was hardly any pattern depletion of the pattern outside of that. Specto data confirmed this depletion observation.

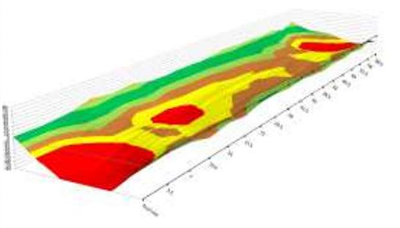

On lanes 7-8, the crowned pair of lanes, everyone stayed much more outside and never migrated that deep - in fact, they never got inside the third arrow. A few factors involved here; gravity simply helps “push” the ball towards the outside, and the ball doesn’t see pattern breakdown near as much because it's rotating "with the slope" - Normal Force is lessened.

Beijing oil pattern breakdown on the crown shaped lanes

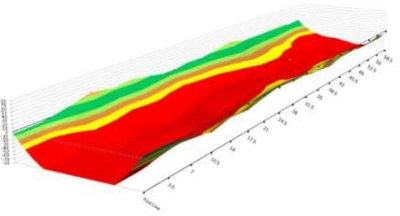

On lanes 9-10, the depressed shaped pair of lanes, the depletion data shows how quickly everyone moved inside and how far they banked it to the towards the outside part of the lane – there wasn't a "hang spot" on that lane.

From our experience we know the ball “sees breakdown" much quicker on the uphill side of a depressed lane because the lane is essentially pushing up against the ball (greater Normal Force) making it “poke through” the thin oil film easier, which causes more friction and makes the players move inside quicker.

Once deep inside and players can play the “downhill side” of the depression the oil pattern might even feel like it has “stabilized” when in fact, it’s just gravity helping the ball “push” towards the outside. In this case, we literally mean push.

This lane shape is the main reason lofting of the gutter comes into play. Along with the pattern "feeling" like it's breaking down quickly, by lofting the gutter cap the ball is able to remain on the downhill side of the depression longer. This allows the ball to retain more energy while also creating a bigger margin for error, along with improved pin carry.

If players tried to stay to the right towards or on the uphill side of the depression, the ball would simply use up energy too quick, minimizing both pin carry and mistake area.

Beijing oil pattern breakdown on the depressed shaped lanes

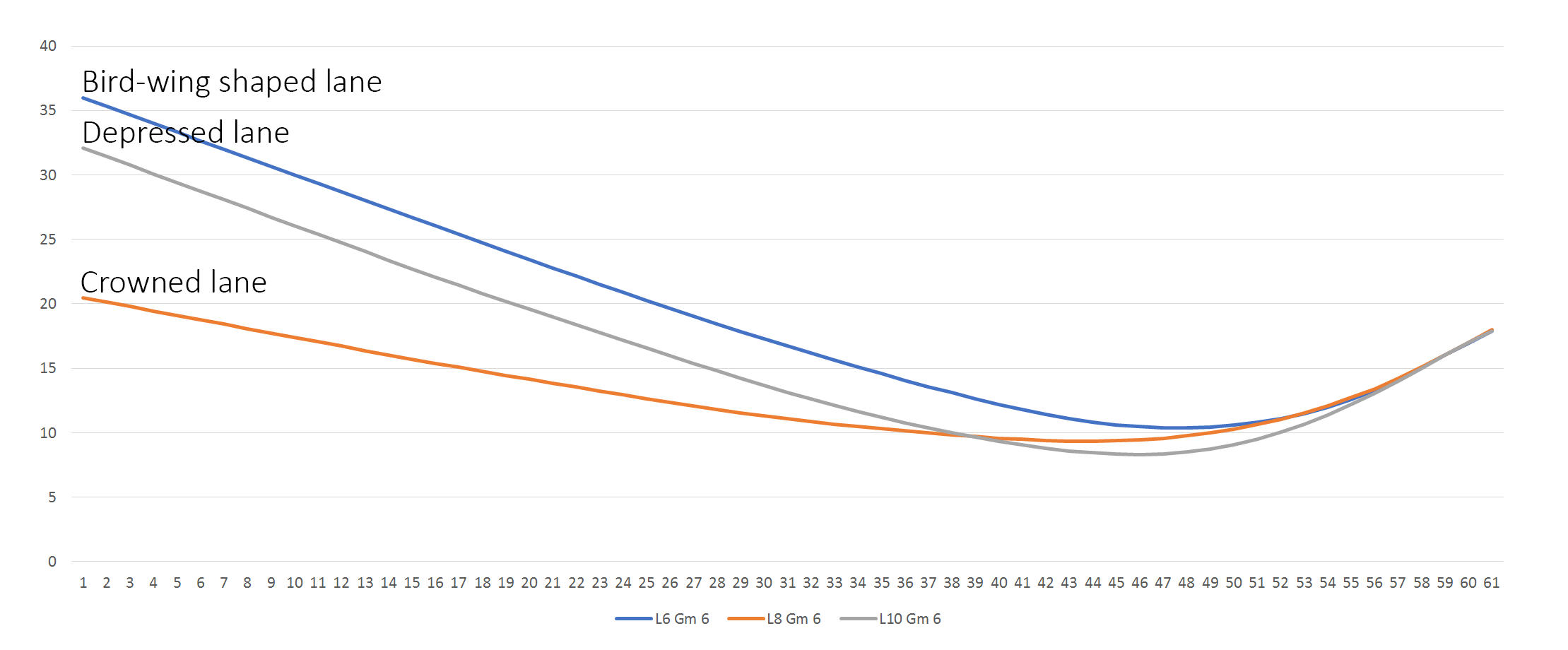

Along with depletion data, we used Specto to track the ball paths on each lane. The below graph shows the average lines of each right-handed player during the last game; the blue line is the bird-wing shaped lane, the orange line on the crowned lane, and the grey line on the depressed lane.

Specto showing the average right-handed ball paths during game six of all three lane shapes

Just like the depletion data showed, the players were most inside on the bird-wing shaped lanes in order to stay away from the hang area and to control the pocket. On the depressed lanes they had more “free hook” so they could swing the ball out farther. And on the crowned lanes, they didn't have to move deep inside so they stayed to the right much farther and played a tighter line.