Changing Lanes

With the invention of the Kegel LaneMapper, came a study about bowling lane topography like no other in the history of the game. Truth be told, when lanes were made of wood, and resurfaced in a timely manner and taken care of by craftsmen, topography was not really an issue. But with the proliferation of synthetic lanes and overlays, along with lanes getting minimal attention today, topography is much different and more influential than in past times – and the Kegel LaneMapper has been able to show it.

We now know what lanes shapes favor different type ball rolls. We know exactly why the same oil pattern can play completely different from one center to another. We know that different lane shapes can affect the durability of an oil pattern, or lane conditioner. And we know that different types of lane constructions are not created equal, nor do they change equally. It’s within this last statement this edition of the Inside Line will focus on – how synthetic panels laid on top of wood lanes can change with seasonal changes.

“All lanes look flat, but they really aren’t.”

We’ve always known that wood lanes change from summer to winter. In the days of regularly resurfaced and maintained wood lanes, we saw depressions go from the minus .010” range to maybe the minus .020” to .030” range in the winter months – a depression increase of 10 to 20 thousands of an inch. In climates where seasonal changes and humidity differences were greater, so were the changes in the lanes.

But today, because of the aforementioned lack of attention lanes receive, we are seeing changes much greater from season to season - especially in climates that have greater seasonal differences.

A big part of Kegel's original Mission Statement was “we study the game of bowling”. It was a mandate from the late John Davis. This edition of the Inside Line will focus on some of that study from bowling centers around the world, and we will show how much, and how fast, bowling lanes with synthetic overlays can change in shape.

Real World

Our first example is from a bowling center located in the northern hemisphere. Being in the north, there can be significant differences in humidity from summer to winter - it is humidity that makes wood change in shape.

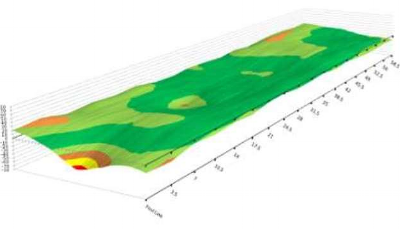

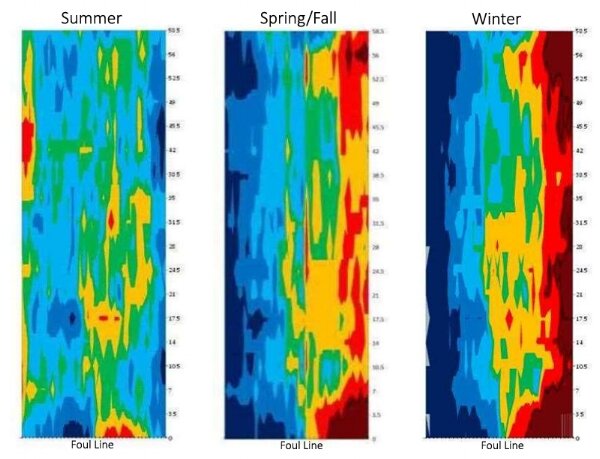

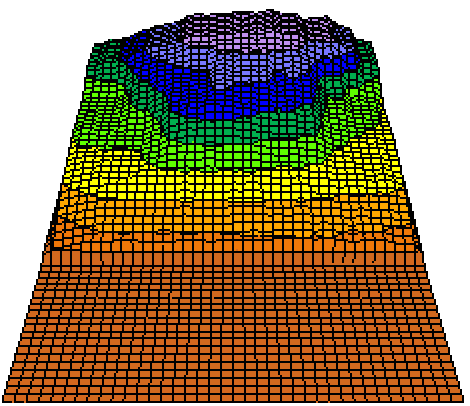

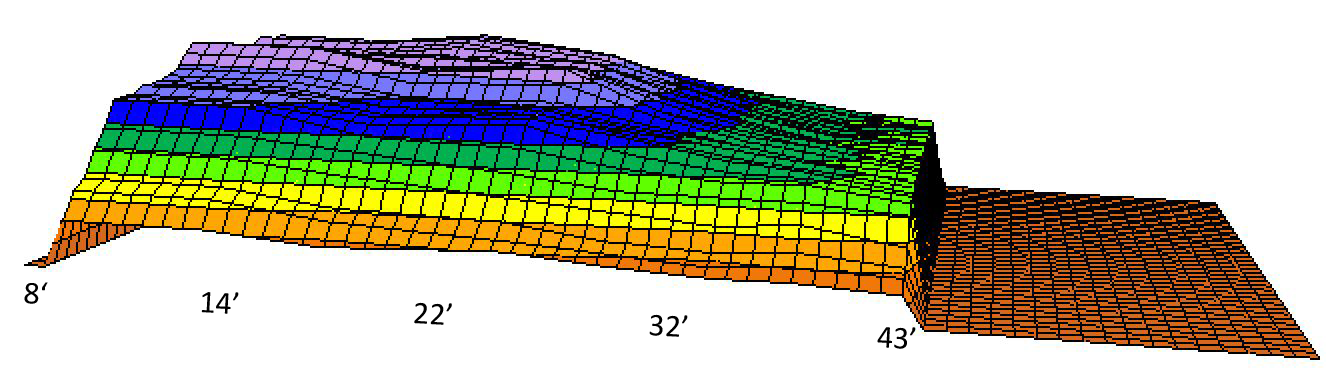

The graphic below is a lane with a synthetic panel on top of existing wood lane (overlay) in the summer time when the humidity is highest. Humidity always enters wood in the area of least resistance and with a wood lane humidity enters the wood from the bottom of the lane.

Synthetic overlay measured in August when humidity is high.

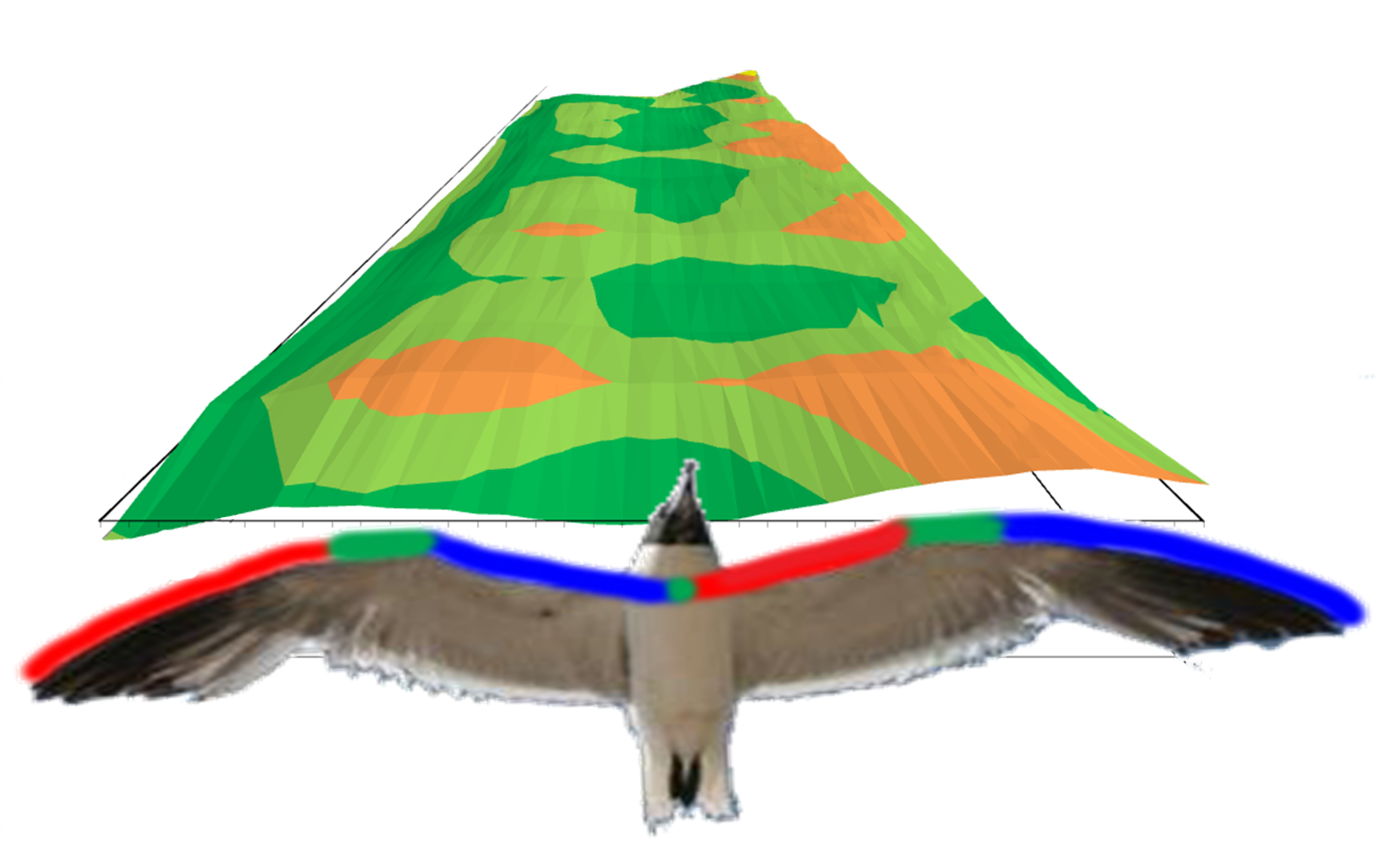

We call this a ‘bird wing’ shaped lane because the wood lane pushes the panel up between the screw rows (2L, 20C, and 2R boards) causing a hill around the 10 board. This lane shape will cause hang spots outside of second arrow, and “hook” inside of second arrow. Medium length patterns are most difficult on this lane shape.

The wood lane underneath the synthetic panel "pushes up" the panel between the screw rows causing the shape of the lane to resemble a bird wing.

What is also interesting is the lanes in this center pass the plus/minus .040” specification at every distance on the lane, in the summer time.

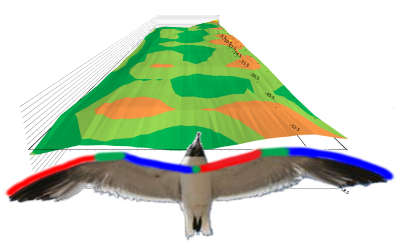

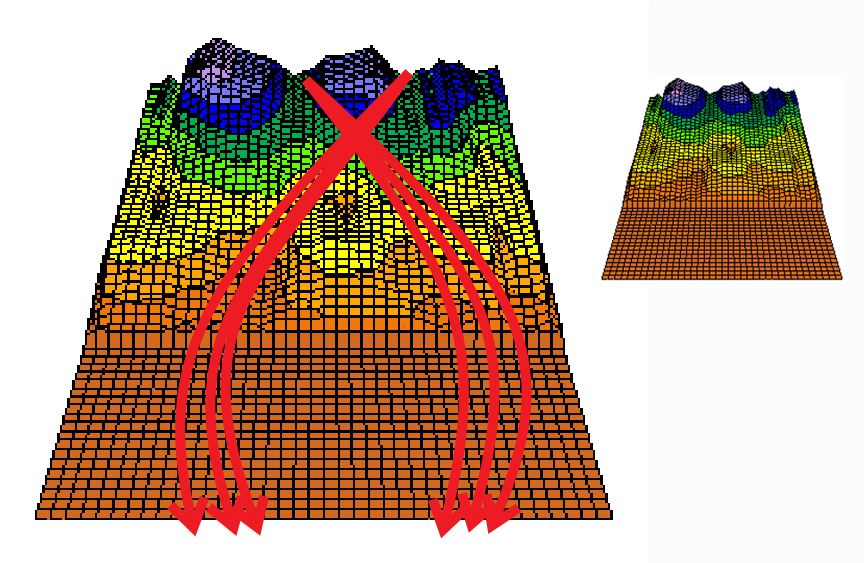

The below graphic shows what the lane looks like during the transition from summer to winter, or winter to summer. In the fall time, the humidity has decreased causing the moisture in the wood lane to also decrease - everything is contracting and the panel takes shape of what’s underneath it. In the spring time the process is reversed. Medium oil patterns begin to play easier - actually all oil patterns begin to play easier.

As the humidity begins to lower, the moisture in the wood lane begins to release, making the wood lane contract. Measurements taken in early November.

Where the lane gets the most abuse, the head area, the depressions begin to exceed the minus .040” specification. The toe screws holding the wood lane together, and the screws that hold the wood lane to the levelers below, are getting loose, or back out all together in many instances. The lane acts like an accordion.

It must be noted that when the heads are cut out and replaced with a substrate like MDF, we do not see these huge depressions. Synthetic panels on top of a substrate like MDF, HDF, or PSL, do not seem to be affected near as much during seasonal changes.

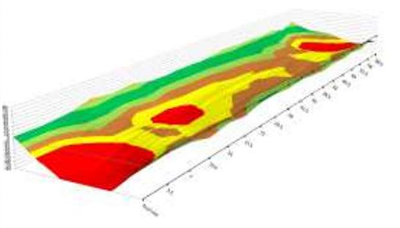

Below is what the above lane looks like in the winter time, when the humidity is lowest. In some instances, bowling centers may even turn the heat on, which lowers humidity even more. It's at this point in the year most of the moisture has come out of the wood lane and the depressions are the greatest. This is also when oil patterns tend to play the easiest; everything “ramps back” to the pocket.

When the humidity is the lowest, the depressions increase the most.

What may be thought provoking for some is, every distance on this lane has now exceeded the minus .040” specification. We have seen this in more than a few instances.

Oil patterns on a lane with depressions of this magnitude will also tend to break down quicker, when playing outside of center. This happens because there is more pressure (gravity) pushing up against the ball when outside of center so it's easier for the ball to "poke through" the oil film on the lane - the “shot” will tend to go inside quickly because of that. Think of a car rounding a curve on a banked road or race track - the banking is there to help a car navigate the turn.

This is when lofting the gutter often comes into play on competitive longer patterns - the ball will “see the lane quicker” as the pattern breaks down on the uphill slope. So players quickly move to and play the downhill side of the depression as long as they can. Physics dictates that the ball will retain energy longer on the downhill side of depression and then hook off of the uphill side easier. Once deep inside, bowlers with high rev rates, high axis rotations, and high tilts will benefit the most on this lane shape - that's physics at work also.

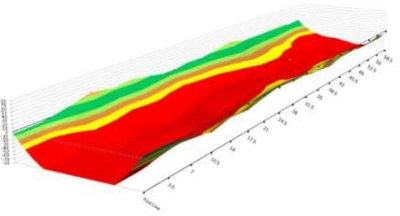

The Kegel Slope Graphs make the slope differences even more apparent:

Same lane over the coarse of seasonal changes.

The Slope Graphs are revolutionary in bowling because they are the first illustrations that show the severity of the ‘rise and falls’ on a bowling lane. Slopes to the right are in the blue color spectrum – the darker the color the more severe the slope to the right. Slopes to the left are in the orange/red spectrum - the darker the color the more severe the slope to the left. Read more about Kegel's Slope Graphs.

How fast can lanes change?

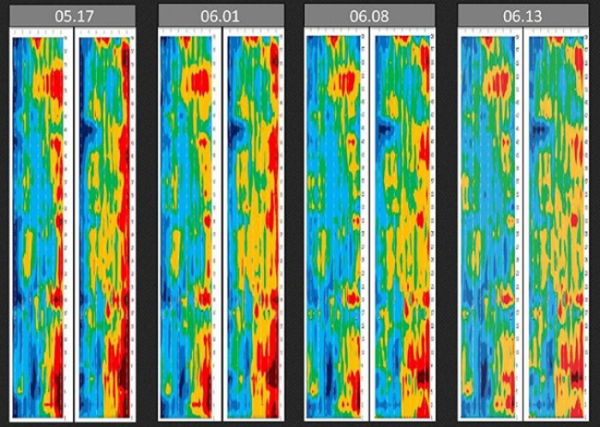

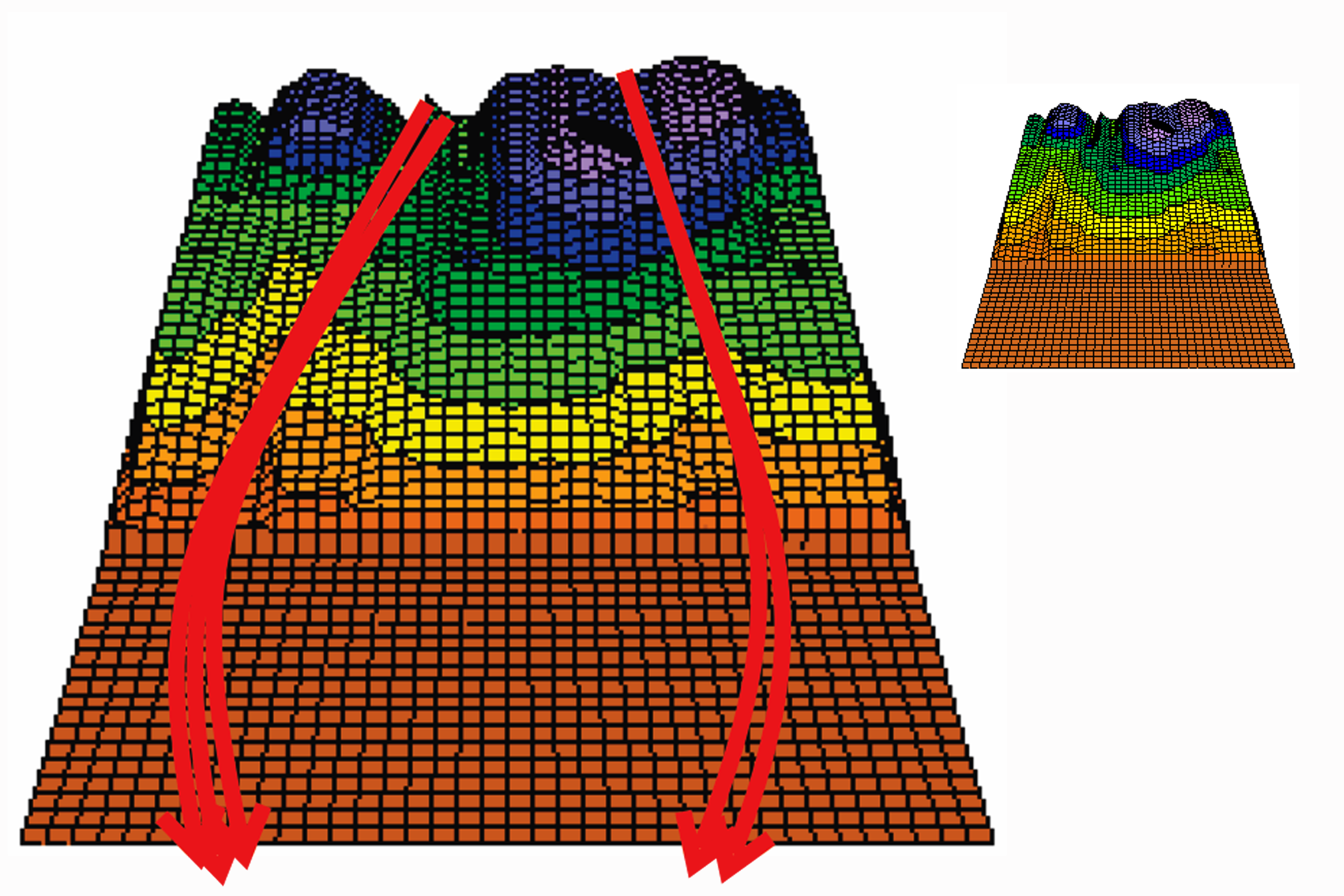

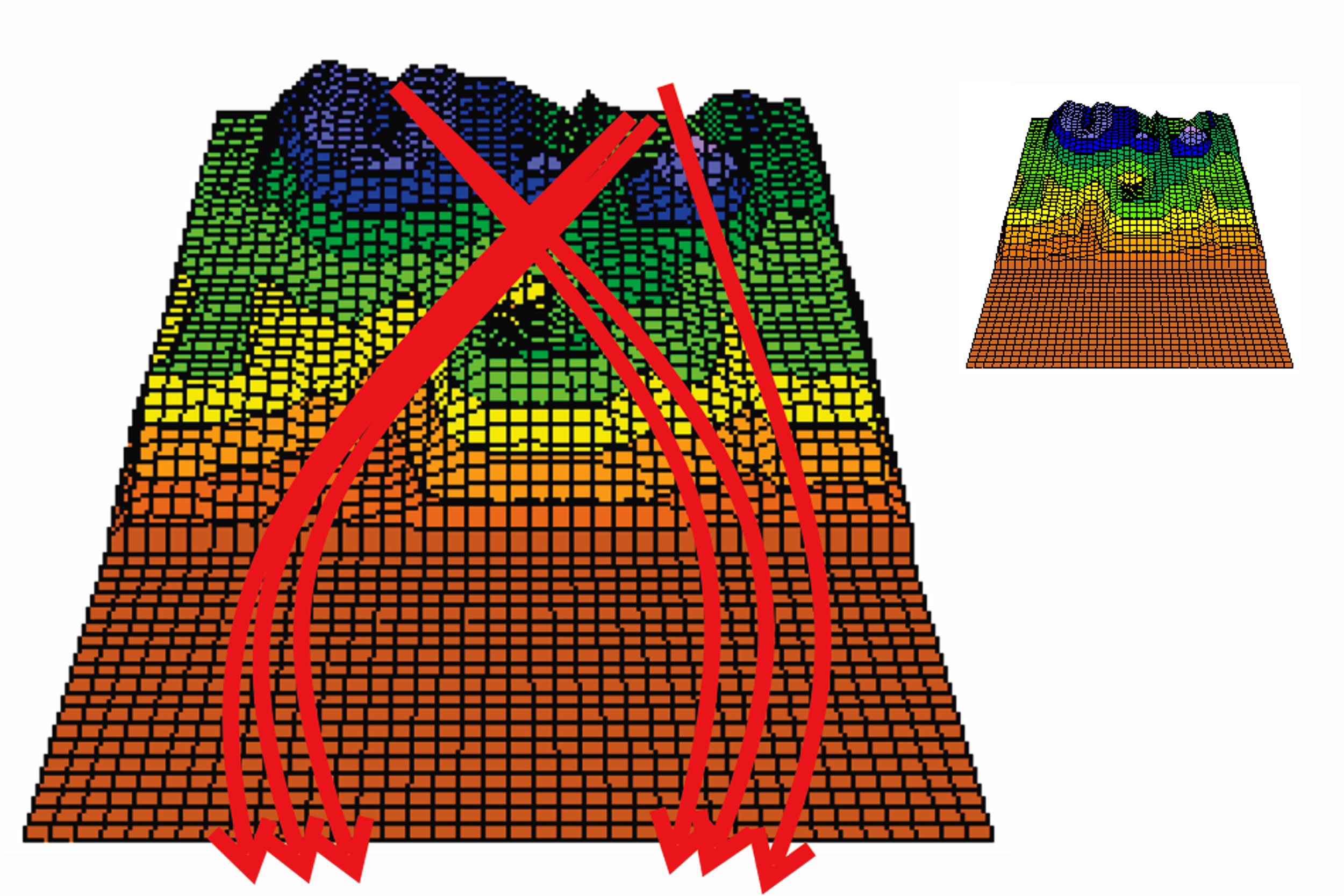

The following graphic shows how a synthetic overlay pair of lanes can change over the course of 28 days – from May 17th to June 13th. This center is also in the northern part of a country and one floor below ground level – so if anything changes are less than a center on the ground floor or above. The foul line is at the bottom of the graphic.

A pair of synthetic lanes with overlays changing during a 28 day period - from May to June. The foul line is at the bottom,

What to notice here are the slopes on the outside part of the lanes – reds on the right are slopes towards center and blues on the left are slope towards center - so the lanes here are predominantly depressed at the beginning of this time frame.

Over the course of 28 days it is clear that the depressions are decreasing. The reds become lighter in color so the movement towards center is less influential, and some areas of the lane are even turning to blue in color, which indicate slopes to the right. Hang spots are caused by these "outward slopes". What we noticed during these 28 days was "the oil pattern" became tougher as the lanes flattened out - gravity always wins on planet earth.

If we talk about the raw data, the lanes were changing (swelling up) about 6-7 thousands of an inch per week as it takes in moisture. In 28 days the depressions went from the mid-minus 30 thousands of an inch to less than 10 thousands of an inch. And the process will reverse itself come fall time as the wood releases all that moisture.

“Gravity always wins on planet earth.”

How this can help you – the proprietor, the bowler, the coach, the federation, or the tournament organizer.

With synthetic lanes it’s even more crucial to see these slopes because it’s the only way we can really understand what’s happening with ball motion – is it friction or a significant slope causing the ball to hook too much, or not enough?

Knowing the shape of the lane at different times of the year will tell you the answer, and it will also tell you how an oil pattern will play, develop, and breakdown.

For instance; when the wood underneath the synthetic swells up in the summer your pattern will play longer or it seems like carrydown comes out of nowhere – the ball has a hard time moving towards center, when the lane is sloped towards the gutter.

This lane swelling can also "make the shot" go more inside as bowlers stay away from the hang area towards the outsides.

This is especially important to any one bowling center when trying to provide lane conditions for their weekly league customer base. If your center has lanes that change as much as these examples, you may need different house patterns for different times of the year so the house playing characteristics stay more similar.

It’s also important to know if a bowling center wants to “experiment” with a different oil pattern or try a new chemical product. If you don't which way your lanes are changing, or how much, it will be difficult to know why things are playing the way they are.

It’s important for tournament organizers or federations to know so when they ask for a pattern months in advance they have a better idea of what to expect come tournament time. Testing an oil pattern in one part of the year and expecting things to play the same at another time of year will often make the question "what happened" arise.

It’s important for coaches and bowlers so they can properly prepare for an upcoming tournament, or make the proper adjustments when the bowling ball is not reacting like they think it should.

Technology can definitely make life easier when used in the proper manner – the Kegel LaneMapper is one of those advances.

When used it can definitely help a bowling center get know their lanes better and use oil patterns that compliment the predominant shape of those lanes to provide more consistent playing conditions for their customers.

Or better yet, the LaneMapper can tell you where and how to correct your lanes if needed so they are "fair" for as many styles as possible.

In a game like bowling, providing equal opportunity for as many different playing styles as possible should be the goal. It worked before and although history may not always repeat itself, it sure does rhyme.

What to LOOK for when choosing a "Coach"

Once you have bowled several games and have a feel for the "game", I think that it is very important (and necessary) to start looking for a "Coach". Why? Improving your scores is essential in getting more enjoyment out of this great game.

Based on your experience (basically how many games you have bowled), will help you to determine just how serious you want to be. The "rule of thumb" and "what to look for" in choosing a Coach is stated below. (NOTE: These are not listed in any particular order, as the reasons are all equally important).

REMEMBER: "You" are the student and you need a good teacher. Interview your prospective Coach to see if they have the following qualifications. You may you need more than one.

• Motivators: All great Coaches in all sports have the innate ability to motivate their athletes. Be sure that your Coach has this ability.

• Fundamentalist: Be sure that your Coach knows the proper fundamentals of the game, from: "push-away" to "timing" to "follow-through", etc.

• Knowledge of Equipment: It is so important in today's game to have a Coach that has a thorough knowledge of bowling balls. Be sure that they do.

• Knowledge of Lane Conditions: With the game getting more and more technical, a Coach that knows about lane conditions is essential.

• Positive Mental Attitude: Does your Coach have a "positive" Mental Attitude? If not, it's time to find one that does.

• Disciplinarian: A tough Coach is the best Coach. If you think that you hate him/her because they make you work hard, you will love them later on.

• Realistic Goal Setter: Are you honest with your Coach? Is your Coach honest with you? Be realistic when you both set YOUR goals. Frankly, being a World Champion is NOT for everybody. "THAT" takes many things and is clearly reserved for a very few of the extremely talented individuals. HOWEVER, there are many other goals that can be reached. Set your goals realistically (best on your team, best in your bowling center, best in your city, best in your state, ABC Hall of Fame, etc.).

I hope that info helps when it is time for you to decide on getting a Coach. You are never too young or too old to start learning and improving in this great Sport.

REMEMBER, NOT everybody is a Coach. Only a few are qualified based on the criteria listed above. I'm sure you have heard a team-mate tell you that you are "dropping your shoulder" or: "not following through". Certainly, they all mean well. BUT - are they telling you ‘why’ or ‘how’ you can fix this particular problem?

Decide today to seek some quality help from a qualified Coach in your area.

The One Thing That Really Makes Oil Patterns Play Different

Normal force, N, is the force that pushes up against an object, perpendicular to the surface the object is on. In other words, the normal force is the force pushing the two surfaces together. The stronger the normal force, the stronger the force due to friction.

How often have you experienced an oil pattern that didn’t play anything like the pattern graph suggested it would? The pattern was ‘x’ length, the high point of the oil on ‘y’ board, yet when you played on it your ball didn’t react anything like you expected, and the optimum pattern exit point wasn’t near where it was “supposed to be”.

From there we look for explanations, and we might get answers like; “the temperature was different today”, “it was raining outside”, “the lane machine put out the wrong pattern”, or who knows what else. In past years technology might not have been available to check things, so theories flourished.

Today, however, we can use technology to confirm the correct pattern is in the lane machine. We can use the Lane Monitor to make sure it was applied correctly to the lane. And with the Kegel LaneMapper, we can even measure the topography of the lanes to see if and how that influenced things.

Knowing and understanding these critical components about our invisible playing environment can help us answer the infamous question every person entrusted with lane conditions has heard at least once in their life; “what happened?”

What lane topographies are most common?

The Kegel Training Center has 12 fully adjustable lanes that can be shaped to mimic almost any lane topography known to exist. After measuring thousands of lanes over the years we have shaped three pairs of lanes in the KTC with some common topographical shapes, and one pair of lanes we consider as “fairly neutral”.

Neutral lanes are not perfectly flat, no lane in the world is, but a neutral lane has topographical slopes on them which do not “overly disturb” the ball as it travels from the foul line to pin deck.

We see neutral lanes often when they are made of wood and resurfaced regularly – these lane types are the “flattest” lanes with regard to topographical shape.

We also see neutral synthetic lanes, but not very often. In fact, of all the synthetic lane bowling centers we have mapped over the years we can count the number of centers having totally neutral synthetic lanes on one hand – it's definitely the exception, not the rule.

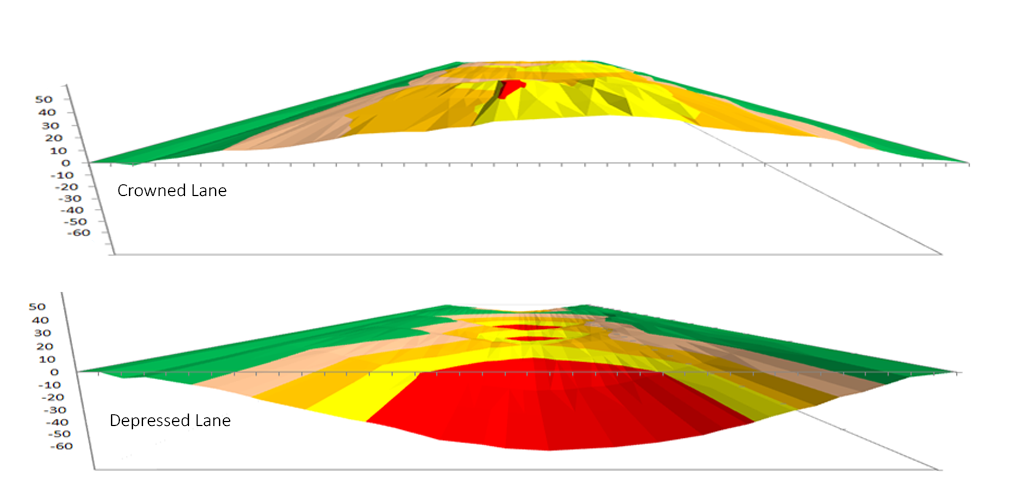

The three most common topographical shaped lanes today are what we call a seagull-wing or bird-wing shape, depressed (dish-shaped), and crowned (mound-shaped). These lane shapes are where things get interesting with regard to oil patterns, how they play, and maybe most important, how they develop as the oil pattern breaks down.

Seagull-wing shaped lanes have slopes towards the center from around the second arrow, and slopes towards the gutter outside of that. This happens because a synthetic panel is mostly screwed down on the outside 1st or 2nd boards on either side and then in the middle on the 20th board. In-between there are no securing screws “holding the panel down” other than where the panels meet, which is only every 10’ or 12’ depending on the manufacturer.

Seagull or Bird Wing Lane Shape

In the summertime when the humidity is high, or in climates with high humidity, we see this lane shape very often - especially when wood lanes are underneath the panels.

Moisture penetration on a wood lane comes from the bottom of the lane where the boards are put together essentially making the lane swell up, which then pushes up the panels in-between these rows of securing screws. This causes the lane to “mound up” around the 8-9-10 board creating slopes towards center inside of that area, and slopes towards the gutter outside of that. The resulting shape resembles a seagull's wing.

Furthermore, in both new lanes with a continuous LSL underlayment (Laminated Strand Lumber - an engineered wood product) and for certain manufacturers who use MDF or LSL to replace the old wood head section, there is a similar securing-screw pattern.

Just like the lane panels themselves, the underlayment is top-screwed in three spots across the lane, near the two outer edges and near the middle, at each of the 30 or so securing locations along the 60' length of the lane. This can also create a bird-wing shaped lane; albeit not as severe as what we see with a wood lane underlayment in high humid environments.

Crowned lanes also happen in year-round climates with high humidity; like Island countries, cities by the sea, or in Southeast Asia. This often happens with overlays where the wood lane underlayment was not screwed down in the middle prior to the lane panel installation.

Depressed lanes often happen in lower humidity climates, or in the winter time, with a wood lane underlayment. In fact, all wood lanes are cut with a slight depression in them, but the longer the panels have been on top of the old wood lane, the more they tend to depress - especially in the area of the lane that takes the constant pounding of the bowling ball, the first third of the lane.

Have you ever notice that scores often go up after Christmas time? This is when a wood lane, or synthetic panels on top of wood lanes, become most depressed because the moisture has finally been released from the wood causing it to contract (shrink). Think of a high banked race track - it's much easier to navigate the curve.

New synthetic lanes can also be installed with a depression, but rarely do we see a nice smooth depression like a resurfaced wood lane has.

Although we see these type lane shapes often down the entire lane, we also see at times a combination of shapes on any one lane. For certain type overlays, we often see very depressed heads and slightly beyond (mostly related to ball impacts), and then bird-wing shapes after that.

In the case of a new synthetic installation, we often see topography slopes that are totally random throughout any one lane, or even within one panel.

Lane shape is more the reason than anything else why certain styles (ball rolls) “match up” to certain bowling centers.

Because of the invention of the Kegel LaneMapper and resulting Slope Graphs, we now know why, and we can show it.

Where the rubber meets the road

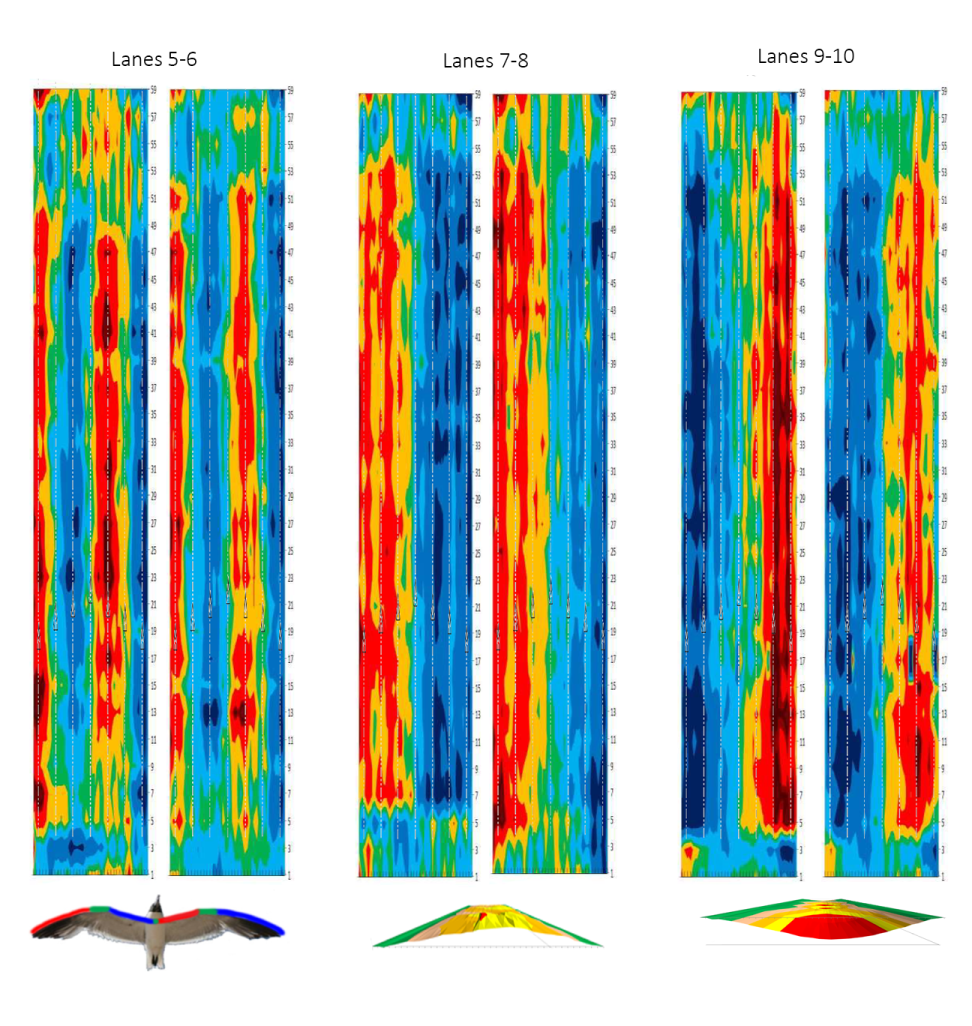

A few months ago the Men’s National Team from Sweden came to the Kegel Training Center with a special request; to learn more about topography and train on lanes with topography differences. So to prepare for their visit we adjusted lanes 5-6 with a seagull-wing shape, lanes 7-8 with a crown, and lanes 9-10 with a depression. We also made sure the lanes remained within USBC specifications.

Below are the Slope Graphs of each pair of lanes:

Remember, the specification for lanes is plus/minus .040”, and it does not specify which way a lane must be shaped in order to satisfy those requirements. The specification also does not state over how many boards those min/max numbers can hit their limit, and that’s where things can get interesting.

For instance, if there is a .024” rise on the lane from the gutter to the eighth board, that’s an average Slope per Board of .003” – that equates to a smooth cross-tilt of .120”. The ball has a very hard time “hooking back to the pocket” on a slope this severe and we see this more often than you might think.

For more about Slope per Board, read this article: Kegel’s Revolutionary Slope Graphs.

So how does lane topography affect an oil pattern and the resulting breakdown?

This is where we have learned the same thing Sir Isaac Newton learned – you can’t fight gravity, you can only work with it.

For a little test and learning experience for all involved, we decided that the 12 players from Team Sweden would bowl six games across the three pair of lanes moving every game – this would make all players hit each pair twice.

There were three left-handed players and nine right-handed players. We chose a medium length oil pattern from the 2017 World Bowling patterns, Beijing.

Here is what the fresh oil pattern looked like, with the foul line being at the top of the graphic:

2017 World Bowling Beijing oil pattern

After 12 games of bowling, we took after tapes on each of the pairs to see how the players broke down the oil pattern on these different lane shapes.

On lanes 5-6, the bird-wing shaped lane, players tried to play outside in practice but the slopes towards the gutter made it play very difficult - they immediately “moved inside” and away from the “hang spot”.

Beijing oil pattern breakdown on the bird-wing shaped lanes

The after tapes show the paths of all balls by way of oil pattern depletion. From these tapes, we can clearly see both left-handers and right-handers played deep inside on this pair of lanes. Our tape data also shows the farthest outside anyone got was on board 9, because there was hardly any pattern depletion of the pattern outside of that. Specto data confirmed this depletion observation.

On lanes 7-8, the crowned pair of lanes, everyone stayed much more outside and never migrated that deep - in fact, they never got inside the third arrow. A few factors involved here; gravity simply helps “push” the ball towards the outside, and the ball doesn’t see pattern breakdown near as much because it's rotating "with the slope" - Normal Force is lessened.

Beijing oil pattern breakdown on the crown shaped lanes

On lanes 9-10, the depressed shaped pair of lanes, the depletion data shows how quickly everyone moved inside and how far they banked it to the towards the outside part of the lane – there wasn't a "hang spot" on that lane.

From our experience we know the ball “sees breakdown" much quicker on the uphill side of a depressed lane because the lane is essentially pushing up against the ball (greater Normal Force) making it “poke through” the thin oil film easier, which causes more friction and makes the players move inside quicker.

Once deep inside and players can play the “downhill side” of the depression the oil pattern might even feel like it has “stabilized” when in fact, it’s just gravity helping the ball “push” towards the outside. In this case, we literally mean push.

This lane shape is the main reason lofting of the gutter comes into play. Along with the pattern "feeling" like it's breaking down quickly, by lofting the gutter cap the ball is able to remain on the downhill side of the depression longer. This allows the ball to retain more energy while also creating a bigger margin for error, along with improved pin carry.

If players tried to stay to the right towards or on the uphill side of the depression, the ball would simply use up energy too quick, minimizing both pin carry and mistake area.

Beijing oil pattern breakdown on the depressed shaped lanes

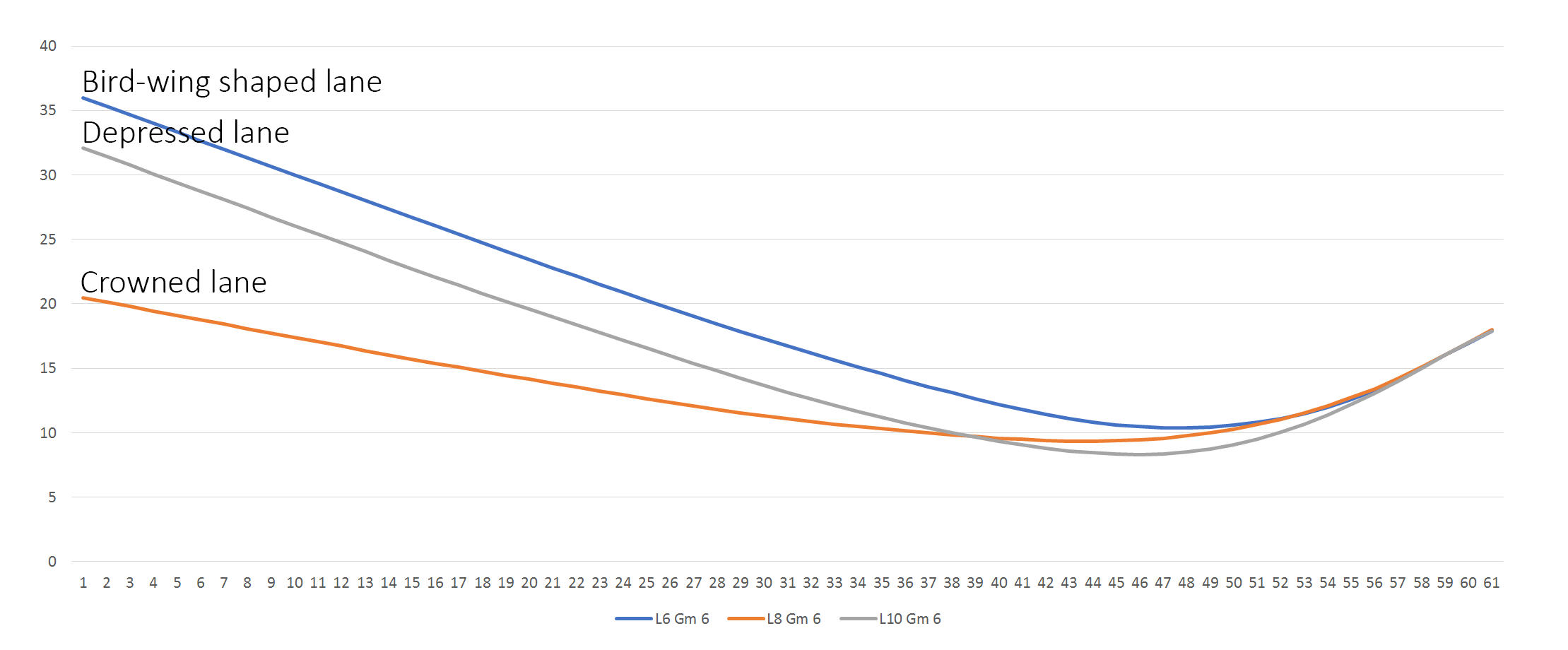

Along with depletion data, we used Specto to track the ball paths on each lane. The below graph shows the average lines of each right-handed player during the last game; the blue line is the bird-wing shaped lane, the orange line on the crowned lane, and the grey line on the depressed lane.

Specto showing the average right-handed ball paths during game six of all three lane shapes

Just like the depletion data showed, the players were most inside on the bird-wing shaped lanes in order to stay away from the hang area and to control the pocket. On the depressed lanes they had more “free hook” so they could swing the ball out farther. And on the crowned lanes, they didn't have to move deep inside so they stayed to the right much farther and played a tighter line.

So there we have it – the same oil pattern, applied at the same time with the same lane machine, using the same oil and cleaner, on the same lane surface, with the same bowlers, but three different lane shapes causing that oil pattern to play different, and break down significantly different.

Topography has been a buzz word for a few years now and we’re really seeing how influential it is, and how it affects lane play. For instance, want to know which part of the lane your ball is influenced by topography the most? Or how different ball rolls are affected by these slopes on the lane surface?

We’ve watched enough over the years to make some conclusions which are not only backed up by results but by physics. Stay tuned, the answers will be enlightening…

5 Must Know Things about Oil Pattern Taper

Oil pattern taper, the amount of lane conditioner in the front part of an oil pattern versus how much is at the end of the oil pattern, has had to change significantly as bowling ball technology has changed. Lane conditioner (lane oil) has two main functions; to protect the lane surface, and to provide smooth predictable ball motion for as many styles as possible.

1 - History

When bowling balls were balanced, the rotation of the bowling ball was very stable and there was essentially one oil ring on the surface of the ball. Front-to-back oil taper with balanced balls is very different than what is needed with modern high flaring balls, which have multiple oil rings on them.

Remember, with high flaring balls, the oil pattern breaks down from back to front and with low flaring balls it’s the opposite, oil patterns break down from front to back. As a refresher, here is an article on that explains how oil patterns breakdown differently between the two types of bowling balls: Breakdown and Carrydown – Then and Now.

At the same time that bowling balls were going through changes, lane surfaces were also changing – “it’s very hard to hit a moving target” was something John Davis used to say often when referring to the art of lane conditioning.

As we have shown often in seminars and online articles, regularly maintained wood bowling lanes are the most consistent type of lane surfaces from lane-to-lane, and bowling center to bowling center. There may be some lengthwise level differences from center to center, but the overwhelming majority of wood lanes were cut with a slight depression, which allowed statements like “the oil pattern taper should be 3:1” to be more valid.

With synthetic lanes however, lane shapes are all over the map, and blanket statements about front-to-back taper, or any oil pattern statement for that matter, can often do more harm than good for people trying to find the best solution for their bowling center.

In measuring hundreds of bowling centers around the world with the Kegel LaneMapper we have found the lanes in any one center follow the same trend as it relates to lengthwise levelness. The only exception to that rule is when bowling centers have added sections of lanes over time.

So if we simply talk about oil pattern taper as it relates to the lengthwise level of a bowling lane, if a lane went downhill we could easily increase the front-to-back taper ratio to help the ball slow down to achieve “good ball motion”. Conversely, if the lanes in a bowling center predominantly go uphill, we might decrease the taper of the oil pattern so the ball would slow down less in order to provide good ball motion for the majority of bowlers.

When lanes were made of wood and resurfaced often, and bowling balls were essentially balanced, it was that simple – but not today.

Today’s synthetic lanes can be crowned, they can be depressed, they can be depressed up front and crowned down lane or the opposite, they can be high right, high left, and anything in between. We very often have seen synthetic lanes that are shaped like a seagull wing; crowned outside and depressed in the middle.

Add the fact that your customers have bowling balls that are still balanced (low flaring) to the very unbalanced kind (high flaring), providing that perfect front-to-back taper can be a challenge.

Of course your daily house pattern is most important for your center, and getting that one pattern “right” can be accomplished, but applying a tournament pattern, or one of the many named patterns out there, and having players expecting it to play similar from center to center is like expecting to win the lottery.

2 - House Shot Patterns (Recreational Type)

Most daily patterns used in bowling centers around the world are of the easy variety – a lot of conditioner in the middle and not much outside. For these type oil patterns, it is most important to control the amount in the mid lane and at the very end of the pattern to 1, minimize carrydown and 2, to open up the outside portion of the lane.

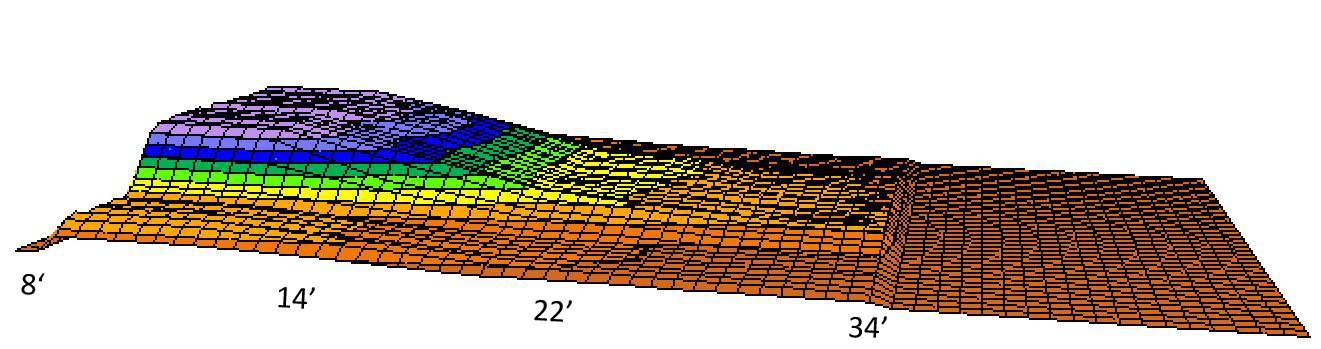

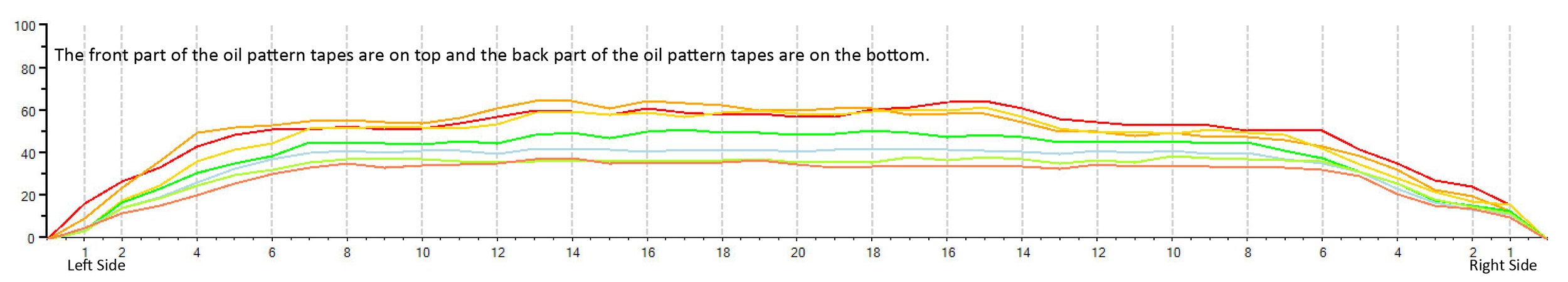

The graphic below is of a typical oil pattern taper when only non-flaring balls were in use. The goal then was to protect and apply conditioner only in the head area and let the conditioner “bleed off” the oil transfer system the rest of the way down the lane to the end of the oil pattern. From 8’ to the end of the pattern was typically a front-to-back taper ratio of 3-4 to 1 and that was with a maximum of 20 units in the head area!

Today’s oil patterns with today’s high flaring balls require a different type of taper, and much more volume. If we start with 80 plus units in the heads, there might still be 50 plus units in the middle to the 30 foot range. We do this in order to provide the bowler with a lot of hold area and decent ball motion, along with providing durability to protect the lane as long as possible.

To get that amount of oil throughout the pattern, the buffer brush must be loaded much more throughout the oil pattern with possibly a much more drastic drop off of conditioner towards the end part of the pattern. The amount towards the end of the pattern should decrease at a rate according to the type of lane conditioner in use and/or lane topography.

Below is an example of a typical daily oil pattern taper using high flaring bowling balls. As you can see, much more conditioner is used throughout the entire pattern.

The outside portion of the pattern has very little conditioner because most centers want to provide the bowler with a lot of mistake area outside of target. So even though we may want some taper there to allow the straighter player to start more to the right, most are concerned about not having too much conditioner towards the outside area in order to provide the largest margin for error possible.

3 - Challenge and Sport Oil Patterns (Competitive)

When designing competitive oil patterns, the goals of a specific oil pattern can vary greatly. If the pattern must play good on the fresh, because of a match-play format for example, finding that perfect taper for game one might be in order. That type pattern will usually be a higher front-to-back taper ratio in order to get the ball to read the lane sooner within the oil pattern.

If the goal is for the pattern to keep players in a specific zone for a longer time, front-to-back taper might not be as important as making sure the end of the pattern holds up for more games. That type of pattern would most likely have much less taper and play more difficult on the fresh, and then become easier as depletion towards the mid and end part of the oil pattern occurs.

A perfect example of an oil pattern with very little front-to-back taper is the 2015 US Open pattern that was used in Garland Texas. The amount of oil in the middle at 8’ on this pattern proved to be in the high 50 unit range, at 22' in the mid 60 unit range, and at 2’ before the end of the oil pattern (41') was in the mid 30 unit range. The front-to-back taper in the middle of that oil pattern was about 1.75 to 1 from 8' to 41', and 2 to 1 from 22' to 41'.

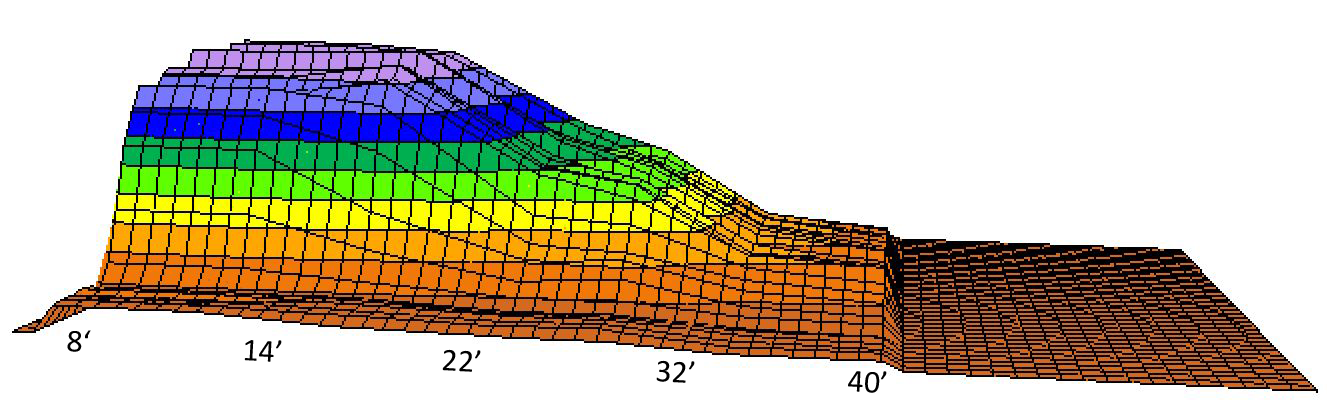

Below are two graphics of the 2015 US Open oil pattern – the 3D and 2D graphs. Lane tapes were taken at 8, 14’, 22’, 27’, 32’, 36’, and 41’.

The pattern goal of that event was to try and keep the players from lofting the gutter, which was accomplished, but we cannot discount what was done with topography at that venue as well. Our studies show topography is always a factor in how oil pattern plays, develops, and breaks down. In this case, the USBC made topography public so we know lane topography definitely was an additional reason the pattern held up so well. (The why will be a future article!)

4 - Lane Conditioners

The lane conditioner you choose also must be factored into your oil pattern’s design. Lane conditioners are developed with specific characteristics and your oil pattern should complement those characteristics in order to benefit from them.

For instance; FIRE and ICE were created for increased durability and both require less conditioner at the very end of the pattern than many of our previous conditioners. If there is too much conditioner at the end of the oil pattern the ball will read the carrydown much more than if, for example, the same amount of Prodigy was at the end of the pattern.

If using our newest lane conditioner, Curve, more conditioner can be applied at the end of the oil pattern simply because it’s a higher friction conditioner, and that will help the ball slow down. Also, the ball won’t “see” what is carried down beyond the oil pattern as much as it would with FIRE or ICE. The trade-off however is durability.

5 - Topography

Now that we have those other factors covered, we can touch base on topography some more and how lane shape affects oil patterns. As we touched base earlier, wood lanes have very similar topography; all are slightly depressed (lower in the middle than the outsides) with the main differences from center to center in lengthwise levelness.

Yes we have more wear issues with wood lanes, which can be corrected with a resurfacing or re-coating, but with synthetic lanes we have more diverse shapes on the lane than ever before in the modern history of the game. Those shapes can vary from lane to lane, and even within the same lane. This makes finding that perfect oil pattern on synthetic lanes across any one bowling center more challenging than ever.

For lanes that are predominantly crowned, lowering the amount of conditioner in the mid lane and at the end of the pattern will help the ball lose energy at the proper rate, which will help provide truer ball motion. Crown lanes tend to act like lanes that go downhill, so anything you can do to help the ball slow down will help your bowlers with good ball motion.

For lanes that are severely depressed, and if you wish your bowlers to play right of center, additional conditioner in the mid lane and at the end of the oil pattern helps reduce friction slightly, and therefore helps the ball not lose energy as quick. Think of depressed lane like a banked curve on a race track – the inside part of the lane is lower than the outside part of the lane so the ball is rotating up the hill causing it to use energy quicker, along with normal force helping the ball move more to center.

For seagull wing shaped lanes, and believe us when we say there are many overlays like this, shorter patterns will need increased front-to-back taper in order to get the ball to read the lane earlier. Yet longer patterns on this lane shape will need less taper simply because from 10-10 the lane is depressed - once the ball gets towards the middle and end part of the pattern it sees the lane more, and sooner, as the oil depletes.

Conclusion

In the article titled Breakdown and Carrydown - By The Numbers, we showed how today the front part of the lane never really depletes to the point of excessive friction unless there is a major wear issue – it’s the mid lane and backend that deplete to the point of the ball seeing a great amount of friction.

Sure the front part of the pattern depletes, but if we start with 70-100 units up front, or less like in the US Open example, at the end of play there is still 30 to 40 plus units of conditioner in the front part of the lane, which is plenty to provide a low amount of friction.

In addition, that part of the lane the bowling ball has the least amount revolutions and the most amount of speed - both of those attributes make the ball “see the lane less” than it does at it slows down and revolutions increase.

The point is, front-to-back taper ratios with today’s patterns is not as important as controlling the amount of conditioner in the mid lane and at very end of the pattern.

If you get that correct in your center, the majority of bowlers in your center will have predictable and controllable ball motion, and back end change (carry down) will be minimal. And for the most part, hopefully, you will have happy bowlers.

Balance Approach All-In-One: What, Why, and How

Giving your bowlers consistent approach conditions from day-to-day may often seem like rocket science. There are a plethora of approach cleaners and approach conditioners on the market. And, there are an abundance of tools to help you in your quest for consistent approaches. Which ones to use; that’s the real question.

Approach cleaners help remove dirt, spills, sticky materials, and other foreign residues from the approach while approach conditioners leave an invisible film that helps reduce the coefficient of friction giving more slide-ability to the approach. These products are often great; initially. But, after a game or two, the film in the slide area gets worn and causes inconsistency between the slide-area and the corners. When this happens, the slide-area is tackier and the sides are slicker (or vice versa) leaving the bowlers with, yet again, inconsistent approach conditions.

We developed Balance with this in mind. We wanted to create a product that was simple to use and that would create a consistent slide environment for bowlers. We also wanted to create a product that would clean and condition the approach in one step.

With Balance, you no longer need a separate approach cleaner and approach conditioner; it’s an all-in-one product that can solve many of your approach problems.

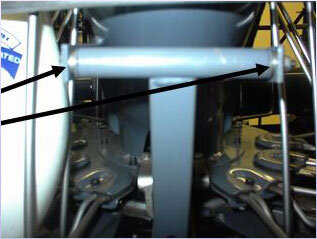

Balance is gel formula that must be applied with a rotary buffer and a buffing pad. A thin bead of Balance is applied parallel to the foul line and about six or so inches in front of the foul line. Using a rotary buffer and the white or green-striped buffing pad, Balance is buffed into the approach beginning at the foul line, working backwards towards the ball return and then back to the foul line. While buffing, there is a visible film that appears. Once the film is no longer visible, the approach is complete.

The buffing pad can be used for multiple lanes. However, once the pad gets saturated, you will need to either flip the pad or use a new one. You can easily tell when the pad is saturated as it will take a long time for the film to disappear, if at all.

Balance won’t leave your approaches slick or tacky. Rather, it evens the sliding environment to make the approach consistent from gutter to gutter. It is recommended to be used weekly or as needed. Because it cleans the approaches and conditions them simultaneously, Balance eliminates the need for multiple products and saves you time by eliminating multiple steps in the approach maintenance process.

Approach maintenance no longer needs to be a difficult task that leads to consistently inconsistent approaches. With Balance, one product cleans and conditions your approaches helping you achieve even sliding approaches across your house while simplifying approach maintenance.

Synthetic Approach Maintenance

Let’s face it; approach maintenance can be a sticky, or slippery, business. There is a fine line to walk when trying to keep the approaches as consistent as possible. Some products offer too much slide causing bowlers to slip while other products can leave behind films and tacky residues that could cause bowlers to stick. Both scenarios are a recipe for disaster that could lead a bowler to an unplanned “Machuga Flop”. And while a flop can be funny, we all know it can hurt and it’s uber embarrassing. But, what is a bowling center to do? How can you maintain the delicate balance of not too slick and not too sticky? We’ve got the answers to your approach maintenance questions.

Some history

Before there were synthetic approaches, all approaches were made of wood and coated with a finish that allowed for proper slide. The only real maintenance to be done to these approaches was the occasional spot cleaning for spills and sticky marks and daily dusting. Then, once every year or so, the approach needed to be sanded and recoated to “refresh” the finish. Wooden approaches have a fairly even slide as long as the finish isn’t worn down. Once the finish started to wear, the approach could be spotty. Generally though, this was just an indication that it was time to refinish the approaches.

Synthetic approaches were introduced when synthetic lanes were introduced. Synthetic approaches were virtually maintenance-free since they eliminated the need for refinishing - or so it was thought. Synthetic approaches came with their own set of problems.

Think of synthetic approaches like your kitchen countertops; not the granite, marble, Corian, and fancy varietals, but the Formica and laminate variety. Layers of materials are pressed or bonded together and an outer layer with the approach image is pressed or bonded to the top. The top layer on which a bowler will slide is often textured and porous. This means dirt and residues can get into those tiny pores and cause build-up. It also means that repeated sliding in the middle of the approach can wear down the texture and cause inconsistencies in the slide-ability of the approach from the middle to the sides.

Because of these issues, a variety of different products and procedures have been developed to help bowling centers maintain their approaches. And what was once billed as an approach that was basically maintenance-free has now become even higher maintenance.

So what’s the right way to maintain synthetic approaches?

If I were to ask 50 different people the proper way to maintain the approach, I’d likely get many different answers. There would be variations of cleaning techniques that used various cleaners and solutions and even just hot water. There would be dust mops, wet mops, buffers, and spot cleaners. The only consistent thing would be that bowlers still complain and the approaches are inconsistent. It’s a vicious and never-ending cycle.

Synthetic approaches require temperature and humidity control. I did some digging, well, Googling, and I found that humidity over 50% can cause approaches to be tacky. We all know tacky isn’t good when trying to slide. To combat this, having some temperature control in the bowling center is absolutely necessary. Additionally, having circulation that pulls or pushes moist air away from the lanes/approaches can help keep moisture from the air from settling onto the approach. The optimal humidity is around 40%.

Dusting the approaches is a necessary task. Dust can settle on the approach and get embedded in the pores. Aside from just causing the approach to look dirty, dust can cause inconsistent slide-ability as well. Dust can cause approaches to be slick and, well, too slick is just as bad as too tacky.

Spills happen

It’s important to clean the spills and wipe away residues. Lane conditioner, soda, beer, and an infinite number of other materials can be spilled on the approaches and every one of them can cause sliding issues. When something is spilled on the approach, wipe it up as soon as possible with a clean, dry cloth. Use a weak dilution of cleaner to remove any sticky liquids. Go back over the area with another clean towel and some IPA (isopropyl alcohol). IPA is very good for removing sticky residues and leaves no residue behind of its own. It isn’t a “cleaner” but it will help remove sticky residues.

Clean those carpets and floors!

The carpets and flooring areas around the bowler’s circles must be kept clean as well. Wax from tiles and residues from carpets and carpet treatments can stick to shoes and can easily be tracked onto the approach. It’s just as important to keep the non-bowling areas clean as it is to keep the bowling areas clean. And, be careful what products you choose for cleaning. Many cleaning products leave behind residues and, as I said before, the residues can easily be tracked onto the approach.

The quest for consistency...

When all of this is done, sometimes you still need some help getting consistent slide on your approaches. There are many products on the market designed to help you with this. Unfortunately, so many of the products available have their own sets of issues. When sprayed, they can get on the lane surface and cause issues with the lane conditioner and pattern.

Dust type products can leave dust residue on the lane and the residue can settle in nearby areas. Some products have to be used very sparingly or the approach can end up being too slick. Some products work great when you first use them, but then after a couple of games, the approach is inconsistent again because the product has “worn off” in the slide area leaving the outsides slick and the slide area tacky.

All of this can be a big frustration. And, it’s one of the common complaints that we hear when dealing with approach questions. People just want a process that is simple and they just want the approaches to be consistent. In fact, I’ve heard from many bowlers that they wouldn’t mind the approaches being a little on the slick side or even a little on the tacky side as long as the approaches could be consistent from the ten pin side to the seven pin side. Bowlers can adjust for a little more slide or a little more stick. But, it’s nearly impossible to adjust when there isn’t any consistency across the approach.

To sum it up, synthetic approach maintenance can be tricky. It can be time consuming and tedious. And, with all of the approach maintenance products available, it can be downright overwhelming. But, the good news is, it doesn’t have to be. Giving your bowlers consistent approaches doesn’t have to be such a mind-boggling task. You can give your bowlers the left-to-right consistency they want on a day-to-day basis with Balance, Kegel’s new synthetic approach maintenance product. To learn more about Balance, click here.

Tech Tip: Interlock Probe

Over a period of years, especially if the mounting bolt has been running loose, the probe can begin to bind if bolt is tightened completely. To correct this, add a #10 s. a. e. flat washer on each side of the spacer. This will give new meat for the spacer to tighten against and will decreases surface tension for the bronze bushing.

Note: This is also handy to convert the old style X-washer pin to the bolt and spacer. Just add a long link bushing to each side to bushing up and a washer on each side.

Tech Tip: Interlock Probe Measurement: Pin Release Lever Set-up

In order to ensure the pin release lever is bent/formed correctly and has not become deformed over time, you must first determine what style of lever you have. You can do this by measuring around the outside. The newer versions measure 9 1/8“. If you have an older version, you can simply cut it down to correct length. Put a nice bevel on the cut lever.

Second, you should confirm that the measurement from outside to outside edge is 5 1/8”.

If you need to spread the lever you can lay it against a closed vice (as pictured) and spread the lever using a rubber or plastic hammer/mallet, but be very careful. To make the adjustment smaller, you can compress in a vice using small increments and re-measuring after each compression.