The Truth About Tournament Oil Patterns and Conversions

At Kegel we get many requests for converting oil patterns to and from different lane machine technologies. Sometimes it can be for a specific tournament pattern or it may be a named oil pattern. Although we fully realize the intent, we also know that there are many factors other than the oil pattern that determine ball motion, and how easy or difficult lanes play.

One technical reason some oil patterns cannot be converted is simply because some lane machines do not have the capability to apply an oil pattern exactly like the machine it was made for. A few of the new longer Landmark Patterns are good examples as these patterns were designed specifically for the FLEX lane machine.

For example, the Eiffel Tower is a 48 foot Sport pattern and with the variable buffer speed upgrade feature the FLEX has, the last seven feet utilizes a buffer speed of 200 rpm which applies a very light film of conditioner in this zone. If a lane machine does not have the variable buff option the buffer will be rotating at 500 rpm, and apply more conditioner to that zone, making the pattern play much tighter that it was intended to play. That doesn’t mean you can’t have fun if applied with other lane machine technology or the pattern will be terrible, it just won’t “play the same”.

However, even if the oil pattern is matched up perfectly from one technology to the next, there can still be differences in types of conditioners used, cleaner type, cleaner dilution, lane surface friction, and lane surface topography. Even bowler differences (who you will follow at the tournament) from your home center to wherever that tournament pattern will be used at can have a huge impact.

For instance, some lane conditioners play slicker or allow the ball to pick up earlier than other conditioners, some conditioner’s carrydown affect ball motion more than other conditioners, and some lane cleaners leave more residue behind than others causing different amounts of back-end hook. The dilution ratio, the amount of cleaner to water mixture, also affects ball motion, especially at the back-end.

For lane surfaces, conditioned wood lanes tend to hook more and earlier than conditioned synthetic lanes. Higher textured synthetic lanes tend to have an “arcing” ball motion, while smoother synthetic lanes tend to be more “skid-snappy”.

When practicing on a tournament pattern at home, you may be all alone or with a small group with similar styles. We know in today’s bowling environment using today’s equipment, it doesn’t take very long to change that oil pattern into something else simply by rolling balls down the lane. Once at the tournament site however you will be following a much more diverse group of styles, which may very well transform that oil pattern into something different.

It’s not even uncommon for us to see the scoring pace change from different squads in the same tournament using the exact same oil pattern just by the style of bowlers on specific squads, or even by the type of bowling balls used by the participants on different squads!

Topography is also a huge variable when it comes to how a ball hooks (how a ball depletes energy) and how much it hooks. A portion of a lane sloped opposite the rotation of the ball will cause the ball to lose energy quickly, while a portion of a lane sloped with the rotation of the ball will cause the ball to lose energy slower. These slopes on the lane surface can also help the ball move more easily towards the pocket, or make it more difficult for the ball to move towards the pocket.

A textbook example of how lane surface and topography can affect scoring pace is from the 2014 and 2015 Teen Masters. In this event, many of the participants played both years, all players use the same type balls, the same oil and cleaner were used, and the long oil pattern was exactly the same both years, so we can discount all those variables.

However, in 2015, the event was held at a newer installation and the lanes are predominately shaped with a certain type topography that is known to produce high scores; the overall scoring pace was 20 pins higher in 2015 than in 2014 and an abnormal amount of 300 games were bowled. The 2015 environment also benefited some players more than others as averages between the two events were 40 pins higher per game in 2015 versus 2014, for certain styles of play.

Kegel has mapped thousands of bowling lanes around the world and we have yet to find two lanes that have the exact same measurements with regard to lengthwise tilts, crosstilts, crowns, and depressions. We also have yet to find a perfectly level lane. It could be said that bowling lanes are like finger prints; no two are the same.

Therefore, perfect and exact pattern oil patterns, or conversions, GUARANTEE that ball motion will be different at home versus where you will play on that pattern at whatever event you are going to.

A good coaching tip is to practice on a competitive type oil pattern that has a similar distance to the tournament pattern you will be bowling on. This type of preparation will help you to keep an open mind and to be flexible when you arrive at the tournament site. It is easy to get overly caught up in oil patterns with all the information and focus on oil patterns today. Unfortunately, more often than not, this closes the mind and shifts focus to “what should be” instead of “what might be”.

In conclusion, if you are practicing at home on a tournament oil pattern, and planning on competing or coaching in that tournament, take that oil pattern with a grain of salt and keep your mind open - very open. We can just about guarantee things will be different at the tournament site than at your home center.

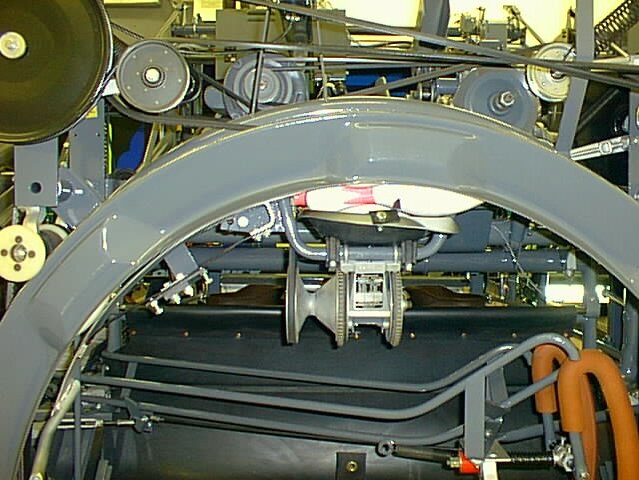

GS Tech Tip: Chain Gear Modification (47-075474-004)

The Setting Tale Chain Gear can, through stress, shear the key on the Drive Shaft. A recent modification added two sets screws to attach the gear to the shaft to prevent shearing. However, an optional solution would be to drill a 1/4" hole through the gear and shaft 90 degrees off of the keyway and install a 1/4" roll pin.

2015 USBC Open Championship Oil Pattern Program Sheet

This month’s Inside Line feature article is about key items on the KEGEL FLEX program sheet of both the Team event and the Singles and Doubles event oil patterns for 2015 USBC Open Championships.

Oil Pattern Distance

Oil pattern distance is one of the main key items to look for on any program sheet. The distance tells us how much dry back-end area is within any one pattern and can give us a good idea of where to play on the lane, providing the lane surface is fairly neutral. Essentially, the shorter the oil pattern is, the farther towards the outside portion of the lane one should play, and the longer the oil pattern is, the farther inside a pattern might play. Of course there are other variables that can affect this theory; like the amount of conditioner on the outside portion of the lane, the shape (topography) of the lane surface, and the friction of the lane surface. However, knowing the distance of the oil pattern, and how it affects your particular style of play, can help you line up quicker than not knowing this important pattern detail.

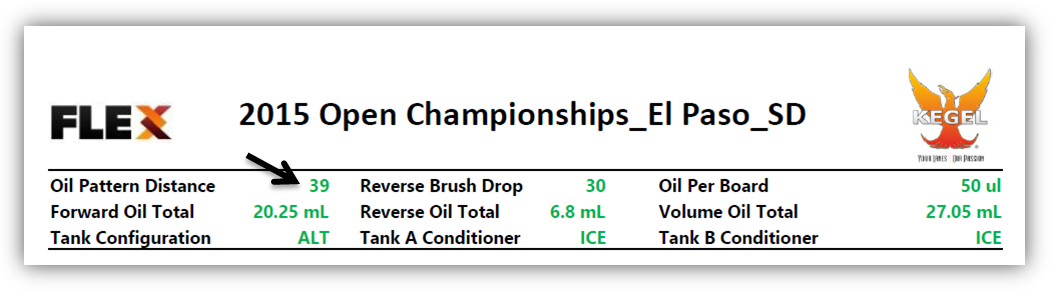

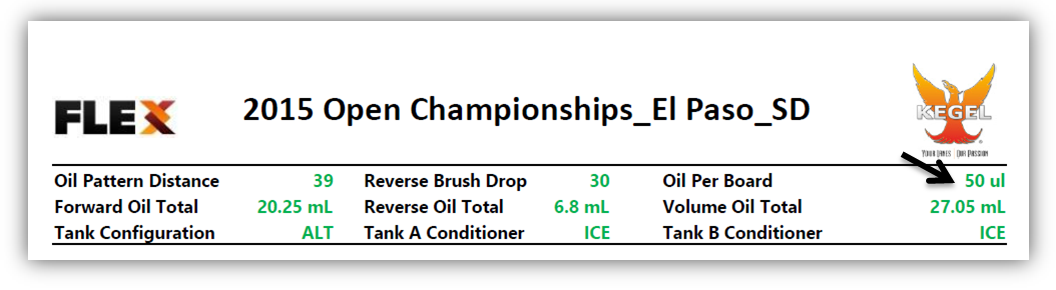

The distance of the oil pattern can be found at the top left corner of the KEGEL FLEX program sheet.

Oil Per Board Value Number

The Oil Per Board value, found at the top right of the FLEX oil pattern program sheet, is the size of the oil stream in microliters - the higher the value, the larger the oil stream, and the larger the stream, the more conditioner is applied to the lane.

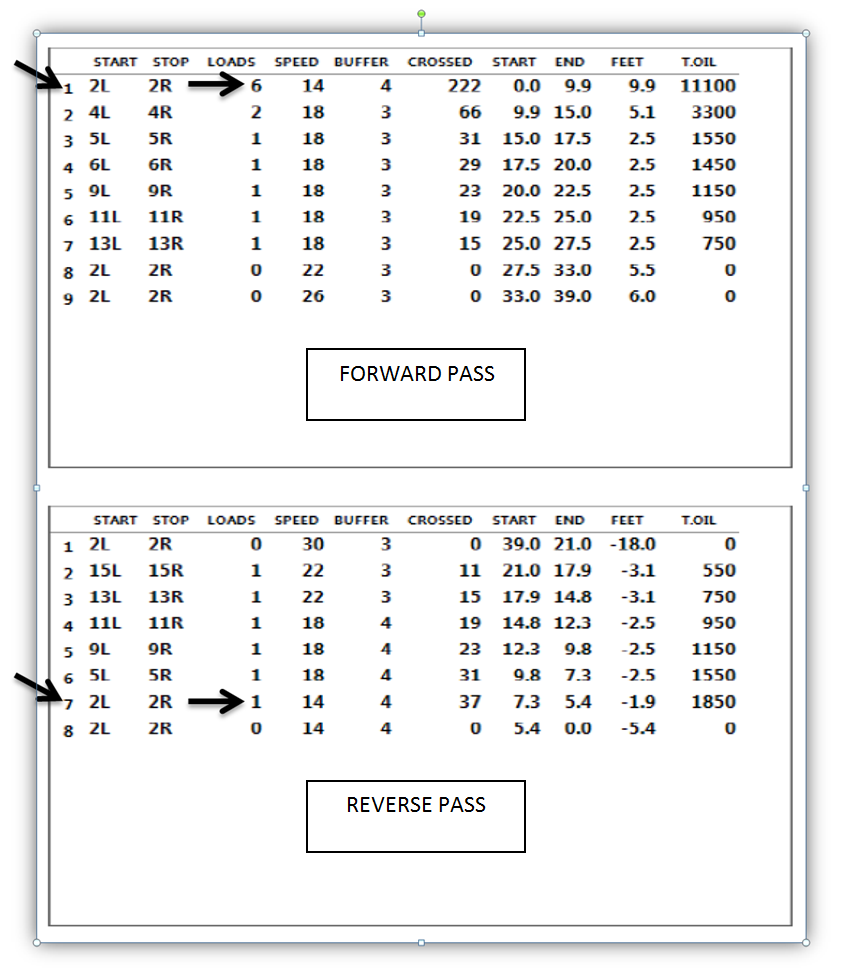

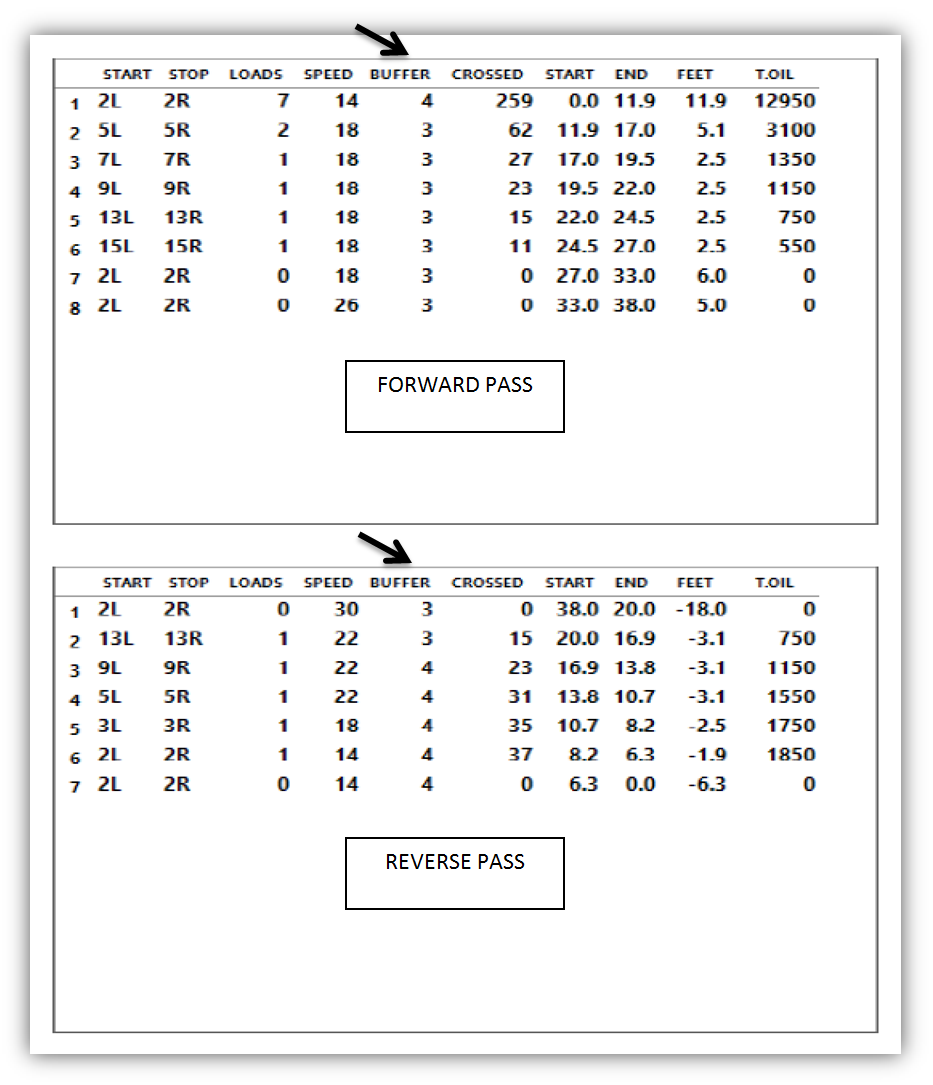

Number of 2-2 Loads

The Number of 2-2 loads can often be a measure of difficulty. Think about these loads as the base of the oil pattern and all loads inside of the 2-2 loads are the shape of the oil pattern. The more 2-2 loads the more difficult an oil pattern will play because once there is a certain amount of conditioner across the entire lane surface, the shape of the oil pattern becomes less relevant.

At this year’s Open Championships, the 2-2 loads make up 12.95 milliliters of the total volume of the 27.05 singles/doubles oil pattern and 14.80 milliliters of the total volume of the 26.90 milliliters team event pattern. In comparison, in most house patterns the 2-2 loads make up 3.7 milliliters of the total volume of the pattern which is in the 22 milliliter range.

The 2-2 loads are normally the first loads on the forward pass and the last load before the buff line in the reverse pass.

Buffer RPM

The FLEX lane machines in use at this year’s championship have four buffer speed options, which are noted on the program sheet by the numbers 1, 2, 3, and 4. Number 1 is what we call slow buff, and it has a speed of 100 RPM. Number 2 is medium buff and has a speed of 200 RPM. Number 3 buffs at 500 RPM and is the default speed that is used on previous models such as the Kustodian ION and Kustodian Walker. Number 4 is high buff and has a speed of 720 RPM. (Note: Individual FLEX owners can customize the buffer RPM settings for their needs, so you may see different numbers on different program sheets.)

The different buffer speeds on the FLEX allow us to do a couple things; one is it allows us to fine tune the front to back taper of the oil pattern without changing lane machine drive speeds. The other is it allows us to condition the lanes in less time by allowing us to apply more conditioner in the front part of the lane without slowing the machine down, as we would have to do in machines with single speed buffer motors.

In short, the faster the speed of the buffer brush, the more conditioner can be applied in any one section of the oil pattern. Conversely, the slower the speed of the buffer brush, less conditioner will be applied to the lane surface.

You will notice on this year’s championship patterns the choice of using buffer speed 4 in the front part of the oil pattern on both the forward and reverse pass of the pattern. Medium and slow buff is not used in this year’s patterns.

The Load Structure

As previously mentioned, once there is a certain amount of conditioner on the lane the load structure becomes less relevant. However, one thing to note this year compared to recent years, and a house pattern, is how none of the loads are “stacked up”. This means the inside load streams are spread out across the oil pattern which makes the pattern a simple blend, or crowned oil pattern (See graphics above).

Because of this type load structure there is not a defined oil line anywhere throughout either the Team or Doubles/Singles event patterns which places a premium on consistent shot making and accuracy. Only once bowling begins, and depletion takes place, can an oil line be developed if, and that is a big if, everyone plays in the same place from the beginning of practice to at least through the first few frames of game one. This is called “managing the oil pattern” in modern bowling vernacular.

This year’s USBC Open Championship should prove out to be one of the lower scoring championships in recent years simply because of the flatness of the patterns. However, it should also prove out to be one of the most competitive because when scores are lower, the gap between the higher scores and lower scores is much narrower.

In closing, if you have not already made the trip to El Paso, practice your spare game, have a good game plan with your teammates, and let your ball be your guide.

"Is Your Center Fundamentally Sound" The View from a Coach

As a coach that travels the country for a better part of the year, and walks into unfamiliar bowling centers on a weekly basis, I hope to shed some light on what a coach really sees in your center, and what you can do as a mechanic to help bring tournaments back to your center year after year. Sitting in a hotel room now writing this, many thoughts run through my mind about what the start of a tournament tomorrow will bring.

Walking though the doors tomorrow I will immediately walk over to our starting lanes. A quick glance of the lanes themselves will give me an idea of how the mechanic prides himself on his daily duties. The first things I will look at are the gutters (not because we will be in them all day), then approaches, and finally the first foot of the lane surface. You may be shaking your head by now, but take a second to think about something… Freshly dusted gutters tell me someone cares about their job and how their center looks to newly invited guests, as do approaches that are spotless, and the fact that someone took the time to clean the first foot of the lane that the machine can not clean.

As the pinsetters fire up for open practice, every lane my players bowl on, they check the foul lights. A foul can be the difference between winning a match or losing by a stick. Did the mechanic take the time to check and inspect every unit before competition started? Since our practice is 20 minutes across the house and followed by ten minutes on our starting pair, I take the first half of the open practice to write in my notebook taking notes on lanes that set pins off spot on full racks, pins that wobble on a 2nd ball cycle, other players that are having sliding issues and how this can affect my team during a tight match where a key spare needs to be made. Your goal as a mechanic is to never give me the right to use my pen.

My ears are trained as a mechanic myself, I don't want to hear multiple calls to the back, nor do I want multiple malfunctions to hinder our fast paced style of play. Bowling for 6 hours and being on our feet all day is long enough without the hassles of waiting for multiple stops on multiple lanes. Believe me when I say at the end of the day I hear all of the good and bad from a variety of coaches on how a center runs. Most coaches are bowlers, and bowlers don't understand the mechanical side of a pinsetter. They expect it to go up and down, return their ball, and work perfect every time they throw a ball. As a mechanic you should provide that experience to the people that are helping to pay your wages.

Take the time in the weeks prior to your event and check your pin spots. Go through a morning routine and reset all of your lanes using the reset button to make sure it works, and watch your racks to make sure all pins are set on spot on a first and second ball cycle. Turn the foul lights on and check them your self and correct any problems you may find. Check all of your hand dryers to make sure they work properly. This will cover most of the front-end things that we see as coaches and competitors, but take it a step further. Inspect your kickbacks for screw heads that may cause ball damage as well as your ball tracks and any transitions (nothing is worse than scoring well and having a screw head take out part of your thumb hole which takes that ball out of your line-up, been there and have the t-shirt). Make sure your parts inventory is stocked so one small part doesn't make a lane go black for the weekend. Go over your stop sheets and make hot lists to fix any minimal problems such as nagging 180 stops, ball returns, or dreaded blackouts. On the day of competition get to the center in time to clean your gutters, clean your approaches, and take pride in doing your lanes and cleaning that first foot that your reliable lane machine can't get to.

In a coaches eye, I don't want to use my notebook to document off spot pins or approach issues, I want to use it to record my moves and ball changes to better me through out my competition weekend. I want to spend my time focusing on my players and their games, not what I would have done as a mechanic to make things better. If I can spend my entire day focusing on how to make my players win, then your bowling center is fundamentally sound and you have the coach's approval.

How can a simple water filter become so clogged?

Anyone that maintains lane machines knows how critical routine maintenance is. But one item that often gets overlooked in lane machine upkeep are supply tank filters - the filters in the oil supply tank, filters in the cleaner supply tank, and now with the FLEX lane machine, the water supply tank filter (see help video below). In this feature article of the Inside Line, we’ll focus on the water supply tank and how those filters can become clogged over time, even though it’s "just water".

Most people are aware that all water is not created equal. Water can be hard or soft, and have different levels of calcium, phosphates, nitrates, sodium, potassium, and chloride, along with some uninvited guests depending on the water treatment plants. These substances are known as Total Dissolved Solids (TDS).

TDS is a measure of the “combined content of all inorganic and organic substances contained in a liquid in molecular, ionized, or micro-granular suspended form.” In layman’s terms, TDS is a measure of the amount of the stuff in the water you can’t see.

Knowing the TDS is all well and good but, how will this affect your lane machine filter?

Well, when water sits around, you know that mold and fungus can grow on the water’s surface. The water can become very pungent; you can actually see things growing and the water color changing. Think about bird baths and small fountains that don’t have running water; the stagnant water eventually turns rancid from mold and fungus growth.

When water sits in a container for long periods of time, a bio-film will eventually begin to form. Bio-films form on surfaces like tank walls and filters. Actually, they will form on virtually every non-shedding surface in a non-sterile or very humid environment.

On your teeth, plaque is a bio-film. In your cooling and heating system, bio-film forms reducing the effectiveness of the system. The slimy stuff you see on rocks and pebbles in streams is bio-film. In stagnant pools of water, bio-films can form on the surface.

Basically, a bio-film can form just about anywhere as long as there is a place for the cells to attach; the cells can attach to a solid surface or to each other.

So bio-films form in water, right? Well, why don’t bio-films form in bottled water at the grocery store?

Bottled water is packaged to prevent bio-films from forming. The bottled water you buy from the store is packaged under nitrogen pressure to force out the air. This prevents bio-films from forming in the water while it sits on the shelf. Once the bottle is opened and air is introduced to the system, the bio-film can begin forming. This is one reason why you shouldn’t reuse bottles from bottled water without thoroughly cleaning them.

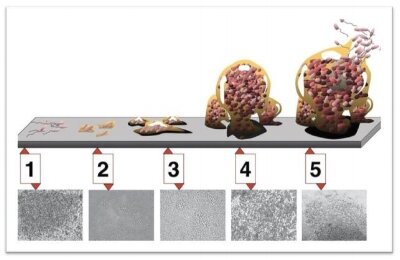

Bio-film goes through five stages of development:

1. Initial attachment,

2. Irreversible attachment,

3. Maturation I,

4. Maturation II,

5. Dispersion.

The picture below shows how a bio-film develops through each of the different stages.

Five stages of bio-film development

Water quality in a specific location will dictate how fast a bowling center will have bio-film develop. TDS and the specific treatment methods used at the local water treatment facilities will change the water quality. Eventually though, every center will have to clean and/or replace their lane machine water filter at some time.

Just like your coffee maker at home, the water filter and supply tank should be cleaned periodically to prevent the problem. If you never clean your coffee maker, eventually the pump will fail. If you never clean your water supply tank in your single cup machines, a bio-film can form in the water tank.

At Kegel, we recommend removing and cleaning the water supply tank filter once a month. We also suggest flushing out the water supply tank at least every couple months, no matter how often you use your lane machine. The water is sitting in the supply tank the same amount of time no matter how many lanes you are doing a day – always.

This is what happens when filters are not maintained regularly:

A filter that has not been maintained.

If periodic maintenance is not being performed on a simple item like your water supply tank and filter, or any filter for that matter, the liquid in the tank will not flow properly and that will change your dilution ratios. We know changing dilution ratios will change ball motion. But, improper cleaning can also lead to a host of other issues.

Just like Sanction Technology has done for the oil system with process verification, with Kegel’s sprayless cleaner system it's easy to check volume output for water and cleaner. As we always say, “it’s better to know than to hope”, and as any lane person will tell you, it's also better for you to find any issues before your bowlers do.

Does lane oil evaporate and how long should the oil pattern sit?

When it comes to lane conditions, every person has their own ideas as to what they think works best. Mechanics, proprietors, and bowlers all have a difference of opinion when it comes to dressing the lanes. Ask 100 different people and you’re likely to get 100 different answers. In bowling, it’s one of those topics that just seems to create a lot of controversy and a lot of differences in opinions.

Because of all these different opinions, we get many questions regarding what the best methods are for ensuring lanes are the same from day to day. Some of these questions stem from curiosity while others, like the one I got last month, stem from bowler controversy.

I was forwarded a message that came in from our website. The proprietor was quite frustrated at his bowlers because his bowlers felt like the lanes were getting conditioned too early and the conditioner was “drying up” before they ever started bowling. The proprietor tried to show the bowlers statisitical data in their score trends that suggested otherwise. But, the bowlers just didn’t agree. So, he asked “the experts”; how long can an oil pattern sit on a lane before it starts to deteriorate?

Modern lane conditioners; every lane conditioner available in today’s market; are all mineral oil based. Kegel uses pharmaceutical grade mineral oil in our lane conditioners so it is of the highest purity available. Mineral oil itself doesn’t evaporate. You could fill a cup with mineral oil and leave it sitting and it wouldn’t evaporate. Here is a link to a safety data sheet (SDS) for white mineral oil. If you look in section 9 (page 4 of the document), it shows the evaporation rate as ‘NA’. This means there is negligible or no evaporation of the material.

There are some chemicals in lane conditioners that will evaporate but these ingredients are minor compared to the percentage of mineral oil. For example, solvents such as isopropyl alcohol (IPA) are often used as an inexpensive way to lower the surface tension. Lowering the surface tension will allow the lane conditioner to wet across the lane surface more quickly. Once the lane conditioner is applied, the IPA would evaporate over time. Since lane conditioners are applied in such a thin film with a low volume over a larger area, we would estimate this to be in the 30 minute range at most. It does not take a lot of IPA to lower the surface tension so it is used in amounts of 1% or less. This evaporation does not affect the lane play characteristics that come from the mineral oil and the other ingredients that are used to give the conditioner its characteristics.

While we’ve never tested the theory of how long a lane conditioner could sit before deterioration begins, a lane pattern could sit, well, forever without deteriorating. That is, of course, in theory since we don’t have a time machine! There are other things; environmental and atmospheric conditions; that will affect lane conditions. But, the conditioner itself could sit for days on the lane and it would still be there; it isn’t going to evaporate away.

While we haven’t tested the ‘forever’ theory, we have allowed a freshly conditioned lane to sit for 24 hours. We took tapes from the freshly applied pattern and took tapes on the same pattern 24 hours later. The results: the tapes were exactly the same for both sit times. The conditioner sitting on the lane didn’t change as a result of evaporation.

Other things can affect the conditioners performance though. Dust from the air or from AC vents can be deposited on the lane. These particles can greatly affect the playing characteristics of the pattern. This is one reason that a good cleaning routine is so important. Applying lane conditioner to a dirty lane will also affect the playing characteristics of the pattern.

Atmospheric conditions like temperature and humidity will also greatly affect lane play and these are more likely the cause of changing lane conditions. Bowling centers see this a lot as the weather changes, especially when there are sharp changes from cold to hot or hot to cold. Bowlers will complain that the lanes are tighter or drier or something else but they don’t always consider the weather changes and that can affect lane conditions significantly.

Here are two previous Inside Line articles that address changing weather and lane conditions: The Weather’s Changing… Are Your Lane Conditions? and Lane Conditions and Cold Snaps.

How long a conditioner should be allowed to sit on a lane prior to bowling is a very common question. And, it’s one that we’ve gotten many times. While consistency is key, we like to support our arguments with science. So, here’s a little science behind conditioner application.

When lane conditioner is immediately applied to a bowling lane, several things must happen before the lane conditioner stabilizes enough to provide consistent playing characteristics. One is allowing the lane conditioner to adhere to the lane surface. This takes about 15-30 minutes depending on the amount of conditioner applied, the type of conditioner, the type of cleaner being used, and the surface energy of a particular lane surface.

The surface tension of the conditioner is also important since the surface tension directly affects how the conditioner “wets” across the lane. The conditioner needs to “like” the lane in order for it to wet across. If the surface energies between the two don’t agree, the conditioner will “sit up” on the lane surface (think of this effect as little beads of water sitting on the surface of your car versus the water sheeting off the surface of the car).

Another bonding takes place within the lane conditioner molecules themselves. These bonding forces, known as van der Waals forces, are basically weak attractions between atoms, molecules, and surfaces. The time for this to take place after conditioning a bowling lane is also anywhere from 15-30 minutes. The below video shows these weak bon

With the amount of lane conditioner being used in today's lane patterns, it takes about 15-30 minutes for the lane conditioner to "settle down" and stabilize on the lane. If time is not allowed for this process to take place, things like excessive carrydown can occur. The lanes may also play "tighter" simply because the oil is sitting up on top of the lane more and there is less resistance to the bowling ball as it rolls through the oil pattern. This is one reason; during tournaments where we provide lane maintenance; we always try to get the tournament organizers to allow a minimum of 15 minutes of lane conditioner "sit time" before the first ball is thrown down the lane.

The biggest key is consistency. It’s one of the things that we preach. Create a routine and stick with that routine every day. If you do the lanes an hour before league, do them an hour before league every time and you’ll eliminate that variable (and that complaint from your bowlers).

We hope this information helps you. If you have additional questions, please feel free to contact us. We will be happy to assist in any way we can. Until next time, happy bowling!

A 100% solids UV LED curable coating

Abstract

A 100% solids UV LED curable coating and the machine for its application/cure has been developed. The machine is equipped with a 395 nm UV LED. The coating is suitable for different flooring applications: VCT, hard wood, laminate, marble, terrazzo, concrete. Some of the applications such as hard wood, concrete and terrazzo floors require a 100% solids UV LED curable primer that has been developed as well. The resulting coating is scratch and impact resistant.

Getting your Pinsetter Ready for the New Season

Maintenance to your pinsetter is important to keep your center running smoothly. In this article, we will discuss some commonly overlooked maintenance items and some tips to help you prepare for your winter season.

Pin Damage

Sometimes pin damage can be easily explained as in the examples below, but some can be much more troublesome to find. Small marks and scratches can accumulate so slowly over a period of time that irreversible damage sneaks up on you and can handicap the appearance, as well as the performance, of the pin.

QUICK TIP: Before you install a full set of new pins for the Fall Leagues, first start with installing one single pin in each pinsetter and run for a shift. Remove the new pin and examine it. If there is any damage, remove the pin and tag the machine for a more in depth inspection.

Usually if pins are getting damaged and showing marks, you can locate the problem area by the evidence of pin chips or shavings. Loose or broken parts tend to scratch the pins, so inspecting all pin delivery paths should lead you to the problem.

Common Problems:

-Pin deck area - Screws, flat gutters, edge boards, and kickback plates

-Broken turret wires and missing deck rollers (A-2)

-Misadjusted turret wires can lead to damage from pulley or center chute (A-2)

-Broken or loose parts on the bin assembly (AMF)

-Missing ball wheel guards (A-2)

-Cracked plows (AMF)

These are just a few examples, but the most important thing to remember is that your problems should be fixed immediately before you risk damaging a new set of pins.

Ball Lifts - See what you can “uncover” before Leagues start!

Ball lifts can easily become overlooked throughout the season since they are an efficient piece of equipment. They run pretty much trouble free so the old saying, “Out of sight, Out of mind!” fits here. Simply doing a quick cleaning and inspection can eliminate the chance of unexpected downtime or ball damage.

Inspection:

-Make sure the lift turns on properly when either pinsetter is powered up

-Inspect belt and belt tracking

-Inspect ball lift tires

-Listen for any unwanted noises

-Check for loose hardware

After the ball lift is cleaned, insert two balls in the trap doors, push them into the lift, and watch the transition through the lift. The balls should move up freely with no belt slippage.

Secondly, with the lift off, take a single ball and manually rotate the top pulley to feed the ball through the lift. The ball should transition through the contact points of the two tires and C track smoothly. If you get binding or slipping spots through the transition, you may need to look at your upper and lower tire configuration.

There are several different kinds of tires and each of these have their own characteristics. Mixing and matching tires in a lift can also create different transition characteristics, so find a combination that works well for your center. Smooth consistent transition is the goal here. A binding lift can cause premature belt wear and may also lead to too much motor strain and amp draw, eventually causing the relays to fail.

By performing regular maintenance and catching problems early, you can help keep your center running at its top performance.

Learn about Kegel Pinsetter Parts