Getting your Pinsetter Ready for the New Season

Maintenance to your pinsetter is important to keep your center running smoothly. In this article, we will discuss some commonly overlooked maintenance items and some tips to help you prepare for your winter season.

Pin Damage

Sometimes pin damage can be easily explained as in the examples below, but some can be much more troublesome to find. Small marks and scratches can accumulate so slowly over a period of time that irreversible damage sneaks up on you and can handicap the appearance, as well as the performance, of the pin.

QUICK TIP: Before you install a full set of new pins for the Fall Leagues, first start with installing one single pin in each pinsetter and run for a shift. Remove the new pin and examine it. If there is any damage, remove the pin and tag the machine for a more in depth inspection.

Usually if pins are getting damaged and showing marks, you can locate the problem area by the evidence of pin chips or shavings. Loose or broken parts tend to scratch the pins, so inspecting all pin delivery paths should lead you to the problem.

Common Problems:

-Pin deck area - Screws, flat gutters, edge boards, and kickback plates

-Broken turret wires and missing deck rollers (A-2)

-Misadjusted turret wires can lead to damage from pulley or center chute (A-2)

-Broken or loose parts on the bin assembly (AMF)

-Missing ball wheel guards (A-2)

-Cracked plows (AMF)

These are just a few examples, but the most important thing to remember is that your problems should be fixed immediately before you risk damaging a new set of pins.

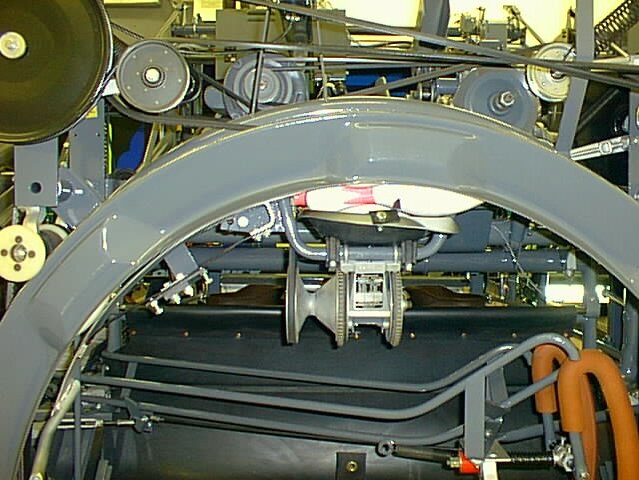

Ball Lifts - See what you can “uncover” before Leagues start!

Ball lifts can easily become overlooked throughout the season since they are an efficient piece of equipment. They run pretty much trouble free so the old saying, “Out of sight, Out of mind!” fits here. Simply doing a quick cleaning and inspection can eliminate the chance of unexpected downtime or ball damage.

Inspection:

-Make sure the lift turns on properly when either pinsetter is powered up

-Inspect belt and belt tracking

-Inspect ball lift tires

-Listen for any unwanted noises

-Check for loose hardware

After the ball lift is cleaned, insert two balls in the trap doors, push them into the lift, and watch the transition through the lift. The balls should move up freely with no belt slippage.

Secondly, with the lift off, take a single ball and manually rotate the top pulley to feed the ball through the lift. The ball should transition through the contact points of the two tires and C track smoothly. If you get binding or slipping spots through the transition, you may need to look at your upper and lower tire configuration.

There are several different kinds of tires and each of these have their own characteristics. Mixing and matching tires in a lift can also create different transition characteristics, so find a combination that works well for your center. Smooth consistent transition is the goal here. A binding lift can cause premature belt wear and may also lead to too much motor strain and amp draw, eventually causing the relays to fail.

By performing regular maintenance and catching problems early, you can help keep your center running at its top performance.

Learn about Kegel Pinsetter Parts