Lane Conditions and Cold Snaps

In last month's article, we touched base on some of the effects weather can have on lane machines, lane conditioner, and ball motion. We wrote about these effects in the sense that the environment has already become more stable. But because of a few recent technical calls, we have decided to release a Special Edition of THE INSIDE LINE, and continue the discussion on how weather can affect lane conditions.

We have found that the biggest problem in a bowling center occurs when there is a drastic and quick temperature change. Kegel's lead chemist and VP of Chemical Product Development, Dennis Sheirs, found this out during the U.S. Open in 1998. For the first two days of the tournament the air conditioner wasn't working in the bowling center, and it was 80 degrees inside the center, and on the lanes.

Sometime in the middle of the afternoon on the second day of the tournament the air conditioning was fixed. Then during that evening someone cranked the air conditioning way down and by the next day both the bowling center, and the lane temperature were 60 degrees.

The bowlers started practice that morning and found the lane pattern played 10 boards tighter. Luckily, since Kegel was doing the lanes and strictly following our Process Verification Procedure, we could prove it wasn't because the laneman or lane machine did something different. But we did learn a valuable lesson; when doing lanes take control of the climate control system!

How does this affect you in daily life?

We find the same thing can happen when you typically get a cold snap up north and it's instant. Normally you will see everything get a little tighter at first. Then as everything goes through equilibrium, and bowling centers kick on the heat, all the other properties change and eventually everything will settle back in. That's when the lanes will start to hook more from the point where they got tighter at.

We said before that when the temperature of lane conditioner gets lower, the viscosity goes up, but that's only one part of the equation. The other part of the equation is the surface tension also increases, which makes the lane conditioner move more until everything settles back down. This can last over a week because during a cold snap the whole system is in flux.

What else can the weather do to my lanes?

During the summer time when the humidity is typically greater, synthetic lanes on top of wood lanes tend to be a bit more crowned towards the gutter outside of the second arrow. We know from our testing, crowned lanes tend to create "hang spots".

But in the winter time, when the heat is turned on in the bowling center or humidity decreases, the wood lane tends to depress, or the crowns decrease, and the panels follow that change in lane shape. This makes it easier for the ball move more towards the center - in other words, hook more. That change however takes a few weeks to fully occur.

If your located in an area that gradually gets colder throughout the year, you won't experience drastic changes because everything is just slowly moving there.

But from our experience, in most scenarios, those quick "cold snaps" (change from warm to cold), tend to make lanes play tighter first. Then, as the inside environment equalizes and the heater settles things down, lanes depress, and that's when we see more hook again.

So as we stated before, typically in the summertime, synthetic lanes installed over wood lanes tend to crown a little bit, and in the winter time, they tend to depress. When measuring lanes using the Kegel LaneMapper, we have documented examples of lanes changing up to .070" from summer to winter and back again - high humidity can create crowns and low humidity releases moisture causing the lane to depress.

In our research, we have found this drastic lane shape change happens only when synthetic panels are on top of existing older wood lanes. Synthetic panels on top of other substrates like MDF/HDF, or LSL do not show much change from summer to winter - only a few thousands of an inch.

Extreme lane shape change by overlays on top of wood lanes is caused by the wood lane underneath becoming "looser and looser" from years of not receiving attention as they did when resurfaced regularly. Basically, the toes screws that hold the boards together, and the screws holding the wood lane to the levelers, start backing out from the constant pounding of the bowling ball, making the wood lane act like an accordion.

Read more about Changing Lanes...

What do we suggest for quick weather changes?

Don't respond to the change too fast - give everything a chance to settle down and get back into equilibrium. Most of the time, our first response is we have to change something when somethings goes haywire - it's human nature.

You are better off to first perform your Process Verification Procedures to ensure your machine is operating correctly, your cleaner is being mixed correctly, and if so, just let everything settle down. Otherwise, you're going to be trying to change something while everything is transitioning.

A non-bowling analogy to the transition is like when you get into a pool for the first time. The water may feel cold, and that could be your first reaction, but if you stay in for a little while, you start to adjust to the temperature. Your core body temperature does not change; you just begin to acclimate to it.

After everything have settled down though, it may be entirely possible you have to adjust your oil pattern in order to keep your bowlers closer to what they are used to. For that just give us a call - the Kegel LaneMapper has provided us with insight and allows us to provide answers much quicker than in the past.

To end, and we can't stress enough, every center is unique and the solutions to any problems are just as unique. Just know that Kegel's Tech Support department is full of dedicated people trying to do the same thing you are; provide our customers with the best possible experience as we can. And don't forget, we are only a free phone call away.

Kegel Road Trip Seminar Videos

During the year 2010, Kegel, along with Storm Bowling, performed a series of seminars throughout the USA. Kegel's portion of the seminar focused on some interesting variables that make up the playing environment.

The You-Tube videos below are of Chris Chartrand presenting Kegel's portion of the seminar. After watching these videos, you will find that there are many things about bowling you probably have never thought of, or even knew about. Enjoy.

Kegel Road Trip Series - Part 1

Kegel Road Trip Series - Part 2

Kegel Road Trip Series - Part 3

Kegel Road Trip Series - Part 4

RELATED ARTICLES

Kegel's Revolutionary Slope Graphs by Ted Thompson

What a Shock - Newton Correct! by Lou Trunk

Weather, Topography, and Ball Motion by Ted Thompson

Topography: What does it all mean? by John Davis

Sir Isaac Newton Knows Bowling by Ted Thompson

The Weather’s Changing…Are Your Lane Conditions?

It’s that time of year again. Leagues began towards the end of summer, the pattern gets tweaked, and everyone starts to get back into the swing of things. Everything is going great and then boom, the weather gets colder and all of a sudden things are different. Then comes the question every manager and mechanic has heard more than they can count - "What happened?"

The products that a bowling center uses to create optimal lane conditions; like lane machines, conditioners, cleaners, and even the lanes themselves, are all physical in nature and therefore temperature dependent. So as temperature changes, the properties and performance of all those products will change as well.

So how do changes in those physical properties show up in the bowling center? They show up in lane machine performance, oil pattern differences, lane topography changes, and of course, what the bowlers feel and see in ball reaction. As the temperature of the conditioner gets colder, the viscosity, surface tension, and density all increase which not only affects ball motion, this also affects different lane machines in different ways.

For this article, we will discuss these changes and offer advice on how to minimize the effects of cold weather on lane conditions. We will focus on the products used to condition the lanes, and in the next issue, we will move on to discuss the topographical changes the lane surface goes through as the climate changes.

Lane Conditioner

In early 1997, we conducted several tests to see how much conditioners changed when the temperature was raised or lowered. What we found was eye-opening. The viscosity of some conditioners changed 2 cps (centipoises) for every 1° F of temperature change. That means if you start with a 20 cps (viscosity) conditioner and the temperature drops from 80° F to 70° F, the viscosity of that conditioner would be 40 cps.

This is not true for all lane conditioners. Some only change 1 cp for every 2° F of temperature change. That is only 25% the change as some of the others, but regardless of how much they change, it's important to know that all of them do.

To minimize this change, look for a conditioner with a higher viscosity index (VI). VI is a way of assigning a value to a conditioner’s resistance in viscosity variation as the temperature changes. The manufacturer of your conditioner should be able to give you this value and guide you accordingly.

Lane Machines

For centers using wick technology lane machines, if the conditioner or lane machine is not kept at normal room temperature, or if stored near a cold wall, the oil will “thicken” and impede the wicking action which reduces conditioner flow onto the lane. As it gets colder, the capillaries in wicks shrink, also restricting flow. Therefore the oil pattern that you started out with at the end of summer might not be the same oil pattern as the weather gets colder.

For centers using Kegel Sanction Technology™, like the IKON, FLEX, and Kustodian line of lane machines, temperature decrease will not affect the output of conditioner like it will in a wick machine. However, if the conditioner gets colder, what you may see is the pressure in your oil pump gauge increase. Fortunately, this does not change the output of conditioner; that’s the beauty of Kegel’s Sanction Technology.

For Sanction Technology lane machine owners, Kegel’s Steve Cross suggests the following when seeing slight pressure fluctuations:

- DON'T PANIC! Expect pressure fluctuations because it is normal with temperature changes.

- Do not change the tubing (pressure regulator). Many people will try to put in a shorter tube to decrease the pressure, but this is not necessary. We have designed a large margin for psi and still have the machine perform as intended. Pressure alone does not affect oil output in Sanction Technology machines.

- Do not adjust the fluid metering pump to adjust pressure. Adjusting the fluid metering pump will increase and decrease the amount of conditioner output (volume).

- Get the machine out early, turn on the oil pump motor, and let it run for about 10 minutes. You should see the psi gauge go back to normal.

Our tech support department receives many calls this time of year with temperature related concerns and we recommend the following no matter what lane machine or lane conditioner you are using:

- Keep the lane conditioner in a temperature controlled environment. The office, front desk, or wherever the temperature is most constant.

- Keep on top of your chemical orders; try to place orders a few weeks in advance to give the chemicals a chance to “acclimatize.”

- Keep the lane machine in a temperature controlled environment so the machine functions properly. If that is not possible, look for other solutions like an electric blanket, packing blanket, or a space heater to help keep the machine warm.

Ball Motion

As we stated before, when conditioner gets colder, the viscosity, surface tension, and density increase. With the increase of these physical properties, more resistance is created on the bowling ball as it rolls through the conditioner. This, in return, usually causes the bowling ball to slow down faster which means it will hook a little more.

Another byproduct of colder weather is the conditioner tends to “stay in place” more which reduces carrydown and therefore, helps the backends stay stronger longer.

Not every bowling center is affected by outside temperature changes but if yours is, our technicians have a couple tips you can employ:

- If when the weather gets colder you notice the bowling balls are hooking more, increase your oil pattern by one foot. This will help bring back the hold area you had when the season began. Once the weather warms back up, decrease the pattern length back to what it was when the season began. Note: Wood lanes with overlays can change in shape which may increase this affect; read about "Changing Lanes".

- If you find temperature changes tend to affect your lane conditions, try to use a lane conditioner that is more resistance to temperature change (higher VI index). Kegel’s Offense HV (for Sanction Technology machines only) is such a product. Offense HV was created when Kegel was entrusted with lane maintenance for the PBA Tour. It was designed to minimize the difference in ball motion from the weekly competition to the TV Show. The TV Show uses many very hot lights that are not present during the rest of the week’s competition. To this day we use Offenses HV when we perform tournaments in venues with less than ideal climate control.

Keep in mind there is no magic lane conditioner or oil pattern that is best for every lane surface or bowling center. Finding a conditioner and oil pattern that is best for your center takes some research and a lot of patience. However, as a Kegel customer you have something going for you; award winning, industry leading tech support by Kegel’s 24/7 Tech Support. Best of all, it’s only a phone call away, and it’s free!

Sir Isaac Newton Knows Bowling

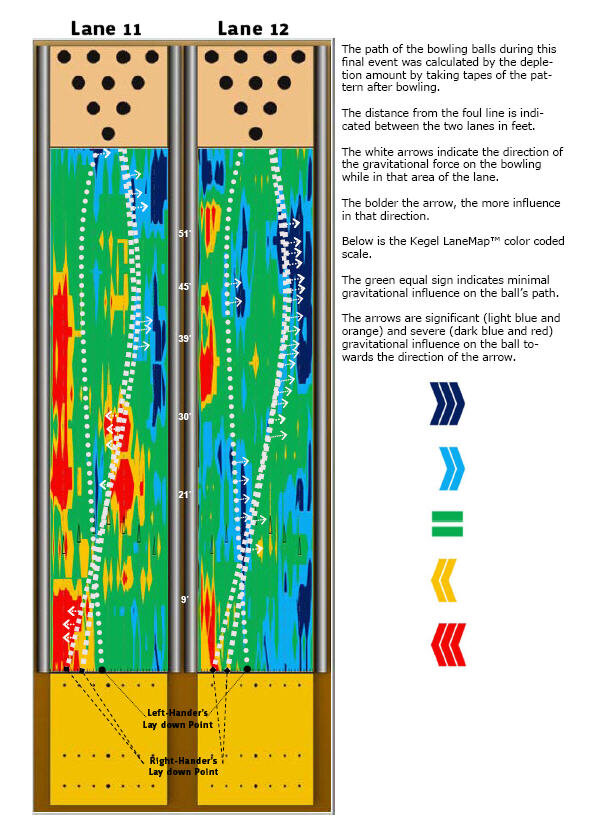

Sometimes pictures, or in this case a picture and a video, explains it best. The video below is the championship match of the Trio’s event at the recently concluded WTBA World Men’s Championship. The picture is the Kegel LaneMap™ of lanes 11-12 at Dream Bowl Palace.

The final match was played on the WTBA Mexico City oil pattern which is fairly flat and 45' in length. Our after bowling tapes showed the optimum breakpoint was around the 10-11-12 boards on that oil pattern at this championship.

The ball tracks of the left-handers and right-handers during the trios championship match are on top of the LaneMap™ Slope Graphs.

Sir Isaac Newton, the father of gravity, was not surprised with the ball motion of the players during this match - Newton has known for a long time that gravity has the same influence on the bowling ball as friction, or lack thereof.

The green areas on the LaneMap™ have very little gravitational influences on the bowling ball. The light blue and orange areas are significant gravitational influences on the bowling towards the direction of the arrows. The red and dark blue areas are severe gravitational influences on the bowling ball towards the direction of the arrows.

Now watch the video below and see if you can see and understand what Sir Isaac Newton already knew. He has been whispering in our ear for many years that it's not always oil or lack of oil (friction), as the reason the bowling ball reacts differently from one lane to the next, or even in certain areas of the same lane.

Pay attention to the right lane and how many light hits the right-handed players have. Then look at the above Slope Graphs in the break point area. Those blue areas signify a significant slope to the right - which is why the ball has a hard time moving to the left. Slopes to the right beyond the oil pattern (for a right-hander) acts like "carrydown". But it's not carrydown causing those light hits - it's gravity,

History - Flattening Bowling Alleys

Flattening Bowling Alleys

- By FRED W. TUERK

Sports Editor, The Star. Peoria, IL

IN its drive for uniform bowling alleys the American Bowling Congress flattened the alleys, but failed to flatten scores. Bowlers and bowling executives were of the opinion that flat alleys, such as offered in ABC tournaments, would greatly reduce the scores.

To the contrary, scores here, especially among younger bowlers, are higher.

With flat alleys one doesn’t have to “know” the drives to locate the “pocket.” A ball clings to its course. It doesn’t take a swan-dive here and a hope-skip-and-jump there. The steam-roller removed all of the dives. Every alley in Peoria was placed under the scrutiny of the Foster Bowling alley-meter during the summer months.

And believe you me that little instrument is about as near human as a mechanical devise could be. It eliminates all guess-work in checking bowling alleys for imperfections. All drives were planned, sanded and leveled, passing a most rigid inspection. Today Peoria has alleys as flat as a pancake. They are as near to A.B.C. drives as is humanly possible.

The natural opinion that prevailed at the time was that the scores would be cut down considerably. Surprisingly it has been to the contrary. Good bowlers are finding it difficult to keep their average over the 200 mark, but the boys who don’t know anything about the manner in which an alley works and who keep throwing at the pins instead of spots, are piling up some terrific counts.

Bowling alley operators appear as surprised as the bowlers. They thought that the radical change would bring about a big reduction in scores. Bowlers like it better. They don’t have to play this alley high and the next one shallow. They all work about alike and the “pocket” seems to be in the same place on every bowling alley in town.

Since the American Bowling Congress is putting forth every possible effort to rid the ten-pin game of the “slots” and grooved alleys we do not hesitate to recommend the Peoria treatment with the aid of the Foster- meter. The new instrument seems to be flawless and gives the A.B.C., as well as the bowlers and bowling alley owners, uniform drives.

The main argument in support of such conditions is that bowlers capable of bowling 220-average at home will be able to come somewhere near that mark while bowling in tourney competition on foreign drives.

In years gone by some of the so-called hot-shots, heavily ladened with hardware for their 3500, 3600 and 3700 pin series struggled, fought and slaved to round out a mere 2650 pin total in A.B.C. competition. They found flat alleys harder to solve than those filled with shellac and ridges.

Those were the clubs that drew the throngs to the A.B.C. gallery and nine times out of ten they proved bitter disappointments. Perhaps on an adjoining pair of drives a team from Po-Dunk drew all the plaudits from the rail-birds while the prima-donnas were presented with the Bronx cheers.

The new set-up, if unanimously adopted and rigidly enforced, should eliminate a lot of trouble and grief to owners of establishments and bowlers alike. Uniform conditions in the bowling game should be the aim of the A.B.C. The organization must, however, see to it that “cheaters” are penalized.

Mere flattening of drives doesn’t mean that all the evils connected with the game are eliminated. Bowling alley machines will still be able to over-load a portion of the drive with shellac to perfect a groove, but we believe that the majority of operators and managers will co-operate with the A.B.C. if a concerted effort is made to eliminate the dragon.

Executive committeemen, city association and league secretaries can greatly aid the parent organization in this drive. It would result in a ten-strike for ten-pins.

Originally Published in the ABC Bulletin in 1936

You might be interested in: ANNUAL Resurfacing Requirement Produces Results Beneficial to Operator and Bowler

History - Trio of "Old Timers"

Trio of “Old Timers” Grow Reminiscent

Over Incidents of Ball-Tampering Days

By THEO B. ZARVER

THE A. B. C. BULLETIN 1938

MILWAUKEE, WIS.— Among the “old timers” who have visited Headquarters this season may be numbered Peter Rowley, who manages the Bensinger Houses in Chicago’s loop, and Roy Davis, secretary of the Chicago 1938 A.B.C. Tournament Association.

While in the office they had the “time of their lives” discussing some of the old phases of the game with Secretary Baumgarten. Of chief interest were the “screwy” things that were done with bowling balls, way back in the “good old days,” long before the A.B.C. had grown to its present status as a truly regulatory body of the game.

In those days ball loading was a favorite pastime, if not something of an art. Oscar Holberg, deceased some ten years ago, had a ball loaded so heavily on one side that it would “walk in” and pick off the 5-7-10 without any great difficulty. Today to do that requires art and precision of a different nature.

Then there was Steve Geroux, who has also passed on to the resting place of all good bowlers. Steve possessed the uncanny ability of an expert in “fixing” lignum-vitae balls. In fact, he made it a business to pick up old balls which had become flattened from being set down on alleys continually on the same side. The first step in the remodeling job was to saw them in two, run a bolt through the faces of the two “good” halves, after countersinking the faces for washers and locknuts. Steve was fine enough artisan that he could even have made a good ball (for those pioneer days) out of the four best quarters of four old balls (maybe).

However, it must be related that Steve did not always do too good a job. In fact one of his jobs “slipped up on him” one night in a match while he was shooting at the 7 pin of the 7-10 split. The contraption split in two, one-half taking the 7 and the other converting the 10. The captains discussed the matter, shook their heads and decided it was “no go” for a spare, since no known rules of the day covered such an emergency.

Another of the old artists discussed was Joe Berlin, who at one time used an old wooden ball which had a rod run through it with a lead weight attached to the center, which could be moved to the right or left by means of wrench and screw driver. This process, as can be seen, controlled the amount of hook or back-up. When Joe found himself on a back-up alley, he would pull out his tools and draw the weight to the left so the ball would “climb in” at a faster pace and pull over the “hump” into the pocket.

Today, thanks to the A.B.C. resurfacing rule, the “humps” are surfaced down and balls of standard dimensions, uniform weight and perfect balance, “climb in” according to the bowling ability of those who use them. Control is now a matter of practice and individual skill with no unfair advantages offered to any.

In the old days balls weighing as much as 22 pounds were in use and many were oversized. In pre-dodo rule days, balls which were called 7-9 balls were made by making a “union” between “better halves” of a 14 pound and an 18 pound ball. The balls of both weights were sawed in half and a 7 pound half vulcanized to a 9 pound half, the holes carefully drilled in the correct spots, and there you had a 16 pound ball—but would “she climb,” due to that 7 to 9 ratio of un-balance.

Scores of incidents come to mind when those who have gone through the “old days” get together and start reminiscing. There is that old one about the “clever” chap who entered an A.B.C. Tournament shortly after the dodo was ruled out. He had his ball weighed and checked, then he poured a load of buck shot into a finger hole and corked it in. He was doing swell up until about the third or fourth frame, when the cork came out, strewing buck shot all over the alleys. And, was that “clever” chap shown the door by officials, or was he? Your guess is right—he WAS, and HOW!

Sit back for a moment, friend reader, and mentally contrast conditions in the “good old days” with those obtaining today, and you cannot fail to see for yourself, how fast the game has progressed in the orderly sense. The recounting of some of the early day experience causes we younger bowlers to think or say: “Cryin’ out loud, is it possible that such conditions were EVER permitted?”

The record bears out the contention that they were, but remember the game was progressing through its pioneering stages during those years. We have done exceedingly well to have progressed with our game to the near-stage of perfection that it has under A.B.C. leadership.

Article originally published in the ABC Bulletin in 1938

Bowling Terms and Glossary

Asian Bowling Federation - ABF

The governing body that embraces all national FIQ member federations bounded in the North by the Arctic, in the South by Australia and New Zealand, in the East by the West Coast of American Continent, with the exception of Hawaii, which shall be in the American Zone, in the North West by the Continent of Europe and in the South West by the East Coast of the Continent of Africa and Madagascar. The Asian Bowling Federation currently consists of 35 member federations.

Ambient Temperature:

Temperature of the surrounding area; same as room temperature.

Approach

The area immediately in front of the lane before the foul line measuring at least 15 feet in length and not less than the width of the lane.

Approved by USBC

Used to describe equipment that has been sent in, reviewed, tested and found to meet all current specifications at the time of approval by the USBC. The WTBA recognizes the USBC as the only approved testing facility for the sport of tenpins.

ASQ

American Society for Quality.

ASTM

American Society of Testing Materials.

Asymmetrical Core (undrilled)

A ball where the RG (radius of gyration) values of the Y (high RG) and Z(intermediate RG) axes of the ball differ by more than 5% of the total differential of the ball.

Axis migration

Path of which the axis point travels across the surface of a ball as the ball travels down the lane; this path will always have the approximate same RG measurement as the ball travels.

Axis rotation

The measurement of horizontal angle through which a ball rotates; rotation is synonymous with the amount of “side roll” a bowler has.

Axis tilt

The measurement of the vertical angle through which a ball rotates; tilt is synonymous with the amount of “spin” a bowler has.

Backend

Portion of the lane after the lane conditioner ends up until the pins.

Ball track

The area on which a ball makes contact with a lane.

Bifilar

The use of two cords or wires to support the test cradle in testing the radius of gyration of a bowling pin.

Breakpoint

The apex (peak) of the hook phase curve.

Center of gravity - CG

The imaginary point inside a body of matter where the total weight of the body is thought to be concentrated.

Certified by USBC

Any competition, bowler, league, center or coach that is registered with USBC.

Coefficient of friction - COF

The ratio of the force opposing the relative motion of two surfaces and the normal force acting perpendicular opposing force. In bowling, this term usually defines the interaction between the coverstock, lane conditioner and lane.

Coefficient of restitution - COR

The ratio of the energy of two objects after impact to the energy before impact. In the case of a ball striking a pin, this is the percentage of energy transfer from the ball to the pin.

Conventional Grip

The method of drilling in which the fingers are inserted to the second knuckle.

Core

The interior of the bowling ball; depending upon the construction of the ball, the core may consist of the inner core (weight block) and/or the outer core (light filler material).

Coverstock

The exterior or outer shell of the bowling ball.

Crack

A partial break or split, slight or narrow, which appears on the surface of the ball. Also referred to as “stress fractures” which often occur around thumb or finger inserts or through the bridge area between the finger holes; a cracked bowling ball is not automatically disallowed from use in certified competition. See Fissure.

Drift

The different in location between a bowler’s starting position and ending position at the foul line.

Durometer

A device to check hardness of bowling balls and bowling pins.

Edge board

The last board on each side of a pin deck or lane.

Entry angle

This is the angle at which the bowling ball enters the pins relative to the longitude of the lane.

Equator

The High RG plane of a bowling ball in symmetrical balls.

European Tenpin Bowling Federation - ETBF

The governing body that embraces all FIQ national federations with tenpins on the Continent of Europe, North Africa, British Isles and the islands of the North Atlantic. The European Tenpin Bowling Federation currently consists of 50 member federations.

Fingertip Grip

Method of drilling where only the tips of the fingers are inserted into the ball. Normally to the first joint nearest the finger tips of the middle and ring finger.

Fissure

A crack of considerable length and depth usually occurring from some breaking or parting. If the fissure reaches the ball track at any point, it is not permitted for use in USBC certified competition as it may damage the lane surface. See

Crack.

Flare

The ball track progression due to axis migration. Flare, also known as Track Flare, is what enables the bowling ball to track over a fresh portion of the surface which increases friction between the ball and the lane.

Friction

The force which opposes the relative motion of two surfaces which are in contact with each other.

Hardness

Resistance to plastic (permanent) deformation due to a constant load from a sharp object.

Heads

This is in reference to the area from the foul line to 20 feet.

Hook Phase

Described as a curve, this is the second phase of ball motion where the ball has encountered enough friction to change direction.

Initial Installation

The first installation of a surface in a brand new center.

Intermediate differential

The difference in radius of gyration between the Y (high RG) and Z (intermediate RG) axes on the bowling ball.

Kickback

The partitions that enclose the pin deck area located on the outside of the flat gutters which are also used to support the pin setting device.

Kickback plate

A plate (3/16” max. thickness) made of USBC approved materials that is used to protect the wood kickback.

Lane and approach markings

Symmetrical graphics on the playing surface as well as any targets meeting USBC specifications.

Launch Angle

The angle in which the ball exits your hand initially at the point of release.

Mass Bias

Y axis or high RG spot on the ball. See PSA.

Midlane

Area past the heads to the end of applied lane conditioner.

Modulus of Compression

Ratio of the unit stress to unit strain within the proportioned limit of material in compression.

Mohs’ Hardness

A scale for classifying a material based on relative hardness determined by the ability of a harder material to scratch a softer one.

Moment of Inertia

Resistance to change in rotation.

Nanometer

A unit of measure used for measuring the wavelength of light. One nanometer equals 1x10-9 meters or 10 angstroms.

Natural pair of lanes

This refers to a pair of lanes used in certified competition. Usually natural pairs of lanes have a common ball return and are numbered 1 and 2, 3 and 4, etc.

Non-approved/Non-conforming

This term is used to describe equipment that has been sent in, reviewed, tested and found to not meet one or more of the current specifications.

Pan American Bowling Confederation - PABCON

The governing body that embraces all FIQ national member organizations sponsoring tenpins from the Americas and adjacent waters otherwise known as Western Hemisphere. The American Zone currently consists of 27 member federations.

Particle

Any additive mixed into the coverstock to change the interaction between the bowling ball, lane conditioner and the lane.

Professional Bowlers Association - PBA

The professional association of competitive bowlings in the United States.

Phenolic

A plastic-like material derived from the chemical “phenol”.

Pin (in reference to a bowling ball)

This is used to indicate where the top of the weight block is located in the ball.

Pin base flat diameter

The diameter of the base of the pin which will contact a surface when a pin is stood upright.

Pin deck

The area of the lane on which the pins are spotted.

Pitch

Angle at which holes in the bowling ball are drilled in relation to the exact center of the bowling ball.

Positive Axis Point - PAP

This is the point on a ball which the ball rotates initially upon release. A bowler’s Axis Point is unique to them and has the potential to change depending on how that bowler releases the bowling ball. The Axis Point includes both a horizontal and vertical measurement from the center of grip.

Preferred Spin Axis - PSA

The axis around which a ball will migrate to and spin around when energy is added to the bowling ball; this will always be the high RG axis of the ball. This term applies to all asymmetrical and drilled symmetrical balls.

Ra – see Surface Roughness – Ra.

Radius of gyration - RG

Measured in inches, radius of gyration is the distance from the axis of rotation at which the total mass of a body might be concentrated without changing its moment of inertia.

Refinish

To put a new protective coating on lanes or pins.

Refurbish

To renew the life of an approved bowling pin by the use of plastic coatings and Nylon reinforcing over the entire pin.

Re-release

A reproduction and subsequent release of an existing (previously approved) product. Re-released products must meet all current specifications and are no longer considered grand-fathered beyond their original approval under previous

specifications.

Roll Phase

The third phase of ball motion where the ball is traveling on a linear path towards the pins.

Roundness

Being such that every part of the surface or the circumference is equidistant from the center.

RS – see Surface Roughness – RS.

Runout

States how far the actual surface is permitted to vary from the dimensions implied.

Scleroscope

An instrument which measures the hardness of work in terms of elasticity.

Serial number

An identifying series of numbers and/or letters in order to identify a specific ball; if a serial number is no longer identifiable then a new one can be engraved in order to give it a unique identifying series.

Skid Phase

The first phase of ball motion; the ball path is in a straight line and has not encountered enough friction to begin it’s hook phase.

Slabbing

The separation of glue joints in a wood core pin or separation of materials in a synthetic lane.

Span

The distance between the thumb and finger holes on a bowling ball.

Surface Roughness – Ra

The arithmetic mean of the peak to valley distances over an evaluation distance.

Surface Roughness – RS

The arithmetic mean of peak to peak distances of the local peaks in the evaluation distance.

Sward hardness

A measurement of surface hardness.

Symmetrical Core (undrilled)

A ball where the RG (radius of gyration) values of the Y (high RG) and Z (intermediate RG) axes of the ball do not differ by more than 5% of the total differential of the ball.

Synthetic

In bowling terms, any pin or lane product not made of wood.

Tail plank

The board on the rear edge of the pin deck to protect and prolong the life of a pin deck. Technically, this is not part of the lane

Thermoplastic

A plastic material which when heated will melt but after cooling will return to a solid shape.

Total differential

The difference between the X (low RG) and Y (high RG) axes values of any bowling ball.

Traction

The friction between an object and the surface on which it moves.

Two-handed approach

Both hands are placed on the ball and are left on the ball throughout the swing until release. At the point of release, a dominant hand releases the ball thereby being a one-handed delivery. Additionally, the dominant hand is determined by the side of the body about which the ball swings.

Two-handed delivery

Both hands impart force on the ball to get it down the lane. Normally done by swinging the ball between one’s legs and is more commonly used when youth start to learn how to bowl. Individuals who deliver the ball from the chest using both hands would be considered to be using a two-handed delivery and therefore must remain with this style throughout competition.

Ultraviolet

The region of the electromagnetic spectrum just below that of visible light generally ranging from 10-400 nanometers.

United States Bowling Congress - USBC

The governing body of the sport of tenpins in the USA.

Vent hole

Any non gripping hole that intersects with a gripping hole at any depth. Any hole intended for use as a balance hole that intersects with a gripping hole will instantly be considered a vent hole.

Void

A manufactured cavity with purposeful size, dimension and/or location within an object.

Vulcanized

Rubber that has been treated with sulfur to make it harder and stronger.

World Tenpin Bowling Association - WTBA

The world governing body for the sport of tenpins.

USBC portions reprinted with permission from Steve Kloempken of the USBC

Are today’s two-handed bowler yesterday’s Dodo bowler?

When reading about USBC’s recent quest to coach the two-handed style of bowling, I could not help but think back to some articles that were shared about the early days of the American Bowling Congress and how the leaders of the time governed the game. In those very early times of governance, when the game was still being defined at a rapid pace, a new crop of hotshot bowlers came into vogue because some of the more ingenious players figured out how to make exotic bowling balls and use them to their advantage. Those early high tech balls were known then as ‘dodo balls’ and the players that used them were called ‘dodo bowlers.’

From 1900 to 1913, the hotbed of dodo ball competition was Cleveland, Chicago, and Louisville. There was a great debate on whether these balls should be legalized or outlawed, which divided bowlers from these cities into factions that either supported or opposed the use of dodo balls.

However in 1913 the ABC, in favor of equipment standardization, outlawed the dodo ball and officially adopted a rule limiting the weight of a bowling ball to a maximum of 16 pounds and "required all bowling balls be evenly balanced".

Some of the early ‘dodo’ balls simply exceeded the 16 pound maximum weight limit and a few bowlers in those early years were using balls that weighed up to 22 pounds to knock down those stubborn pins. The extremely heavy ball, called a “phony” at the time, gradually went away as bowlers discovered the greater effectiveness of the unbalanced dodo ball.¹

The most common way of loading a ball in the early 1900’s was called the “7-9” combination; where a 17 pound ball was cut in half and cemented to half of a 19 pound ball. The extra weight was primarily used on the left side of the ball, but not always.

To make the dodo ball as effective as possible, nearly everyone used a two-finger grip and common practice was to drill both finger holes the same size. Then the only thing the dodo bowler needed to do to significantly change the "action of the ball" was reverse their grip.

This is where today’s two-handers may be missing the boat, or at least not hopped on board yet. With today’s bowling balls and their dynamically unbalanced cores, by flipping the ball around 180 degrees, a two-hander can get two distinctly different ball motions out of one bowling ball; much like the dodo bowler of the early 1900’s.

By strategically placing the core in relation to their PAP, if rolled in one direction that one ball could have a significant amount of flare potential but when turned around and rolled the other way, it could result in almost zero flare potential.

Note: Since the article was written in 2010, experimentation has continued and some two-handed players, or no-thumb players, have even used a drilling with three holes, increasing layout options for these players. Please refer to “Drilling Specifications” section of Equipment Specifications and Certifications Manual which can be accessed via USBC web site. Also, the USBC has added additional limitations to the ball rules of the 2016 US Open.

On the majority of bowling conditions, when side rotation is employed on the bowling ball, the amount of potential hook is directly related to flare potential. Flare is what enables the bowling ball to track over a fresh surface every revolution which increases the amount of friction between the ball surface and the lane surface.

The extreme amount of flare today’s weight blocks create is mainly what prohibits a bowler using a traditional grip from doing this. If two thumb holes were drilled into the ball, not only would it be difficult to statically balance out the ball and the core layout, the flaring action would eventually roll over one of the thumb holes. When the ball track rolls over such a large hole like most thumb holes, it can jump up off the lane causing unpredictable ball motion.

But a two-handed player does not use or need to drill a thumb hole and therefore could drill their finger holes in the middle of the CG and rotate the core as they see fit. When not drilling a thumb hole into a ball, all the player has to do is satisfy the ‘one ounce in any direction limitation’ set forth by the WTBA , the world governing body of tenpin bowling. The UBSC recently changed their balance rules for bowling balls drilled without a thumb hole and now allow up to three ounces top or bottom weight.

In events that limit players to the number of balls they are allowed to check in for competition, like the WTBA World and Zone Championships, this technique could prove to be particularly advantageous over players relegated to using a thumb hole, or not having the ability to turn the ball around 180 degrees. If done strategically, that 6 ball limitation could become 12 balls for the two-hander. Players using thumb holes do not have this option.

In the early 1900’s, even though there was a clear advantage to use a dodo ball, it was not that popular during those years for two reasons; the dodo ball was difficult to control and there was a strong desire by the ABC to bring ‘fair standard conditions’ to the game.¹

As previously mentioned in my “I’ve been thinking too” article, the modern high tech bowling ball, when used on flatter oil patterns, is also extremely difficult to control and very unpredictable for the less skilled. This volatility is why blocked lane conditions are favored by the majority of bowlers.

Simply put, with the highly sensitive and frictional bowling environment of today, blocked lane conditions are more predictable and therefore just more enjoyable for most bowlers.

Perhaps the two-handed game will also remain a technique for very few since that style is also “difficult to master” and an extreme departure from the style so many have already learned.

As far the game today having ‘fair standard conditions’, like the dodo bowlers of the early 1900’s could do with dodo balls, so can two-handed bowlers with the modern ball. And that contradicts the founding fathers decision that “all bowling balls must be evenly balanced.” A component to the game they felt was necessary in order to have “fair standard conditions.”

¹Bowling Magazine – November 1960 – Dizzy Doings of the Dodo