The Use of Poseable Mannequins During Bowling Motor Skill Training

Originally published in Bowling This Month

All athletes go through several stages during the process of motor skills training.

During the first stage, the athlete must be given all the information needed to form an image of the movement being practiced in his or her mind.

The next stage is when the athlete starts to master the new movement. This stage is characterized by the conscious control of all actions, slow movements, a significant amount of errors, and being easily distracted by external or internal stimuli.

The final stage of skill mastery is evident when the athlete starts performing movements automatically, without conscious control, using an optimal rate of movement, with an error rate that is trending to zero, and has a stable resistance to external or internal distractions.

Forming the image of the skill in the mind

The role of the first stage of mastering a skill is often underestimated. It is critical that the information be delivered in a way that is accessible and understandable to the student so that they can form the correct image of movement within their mind. In my observations, sometimes 15 minutes effectively spent at this stage can save dozens of hours of training in the later stages of mastering a skill.

This important first stage will be discussed in this article, and I will include my experience with optimizing this process. Future articles will cover the next two stages.

Methods of image formation

As a coach, one must use all possible channels of education to help the athlete create the correct execution of the skill within their minds. The visual, auditory, and kinesthetic learning modalities should be used effectively as needed for each student. In general, the effectiveness of training will increase significantly when a combination of these modalities is utilized.

In fact, the uptake rate and quality of understanding increase dramatically when combining all three perception channels. Research has shown that when using just auditory or visual channels separately, only 10% of new information is absorbed. The combination of audio and video helps to increase the uptake level to 50%. Adding the kinesthetic channel to the other two provides an optimal rate of 90% of new information being understood. Thus, the integrated approach of using all three learning modalities is the most efficient. Of course, the coach needs to recognize and take advantage of the athlete’s dominant channel of perception.

During the initial stage of skill training, it is necessary to create a complete field of information for a given skill set.

During the later stages of skill encoding, the most efficient implementation is to work with the channel of perception which “delivers” information in the form closest to the type and kind of thinking directly involved in the learning process and the implementation of a given skill. For example, when mastering a skill that predominantly uses spatial and visual thinking, it is usually most efficient to use the visual channel as the dominant one and the others as complementary. Or, if the proprioceptive senses are mostly involved, it is recommended to use the kinesthetic channel of perception as the dominant one and the other channels as complementary.

The critical role of spatial and visual thinking in bowling skill-building

Spatial thinking is an activity that helps the athlete create mental images which they can adapt to solve practical and theoretical problems. Following this definition, we understand that it is this kind of thinking that is dominant when we are teaching and training different skills in bowling. A well-developed sense of spatial thinking will greatly enhance the bowler’s ability to learn and understand many physical and analytical skills related to bowling.

In the bowling alley, where in addition to a good technical throw, the player is required to understand motion phase analysis of the ball along it’s path (skid, hook, and roll), changes in the oil pattern, types of pin action, and much more. In virtually all stages of the training process, spatial and visual thinking modalities are absolutely essential tools for a player’s success. Equally important is the development and the effective use of these kinds of learning modalities for the coach’s success in training their athletes.

Spatial and visual thinking in forming motor imagery

Spatial and visual thinking allows a player to simultaneously work on understanding technical elements of the physical game as well as forming motor imagery in the player’s mind (i.e. it can be used as the first stage of motor skill formation). Some elements of this technique are similar to the motor imagery practice, but it is simpler to use and does not require special training.

We must simplify the process of mentally visualizing a technique to the point that the player can easily press “play” in their mind in order to see the technique played out. The creation of a mental image of a practiced movement is a prerequisite for its further improvement. The rate of a player’s improvement depends largely on the degree of detail and accuracy given to this mental imagery. Plus, fine motor skills will be used to develop such thinking skills as reaction time, attention, coordination, imagination, observation, and visual and motor memory.

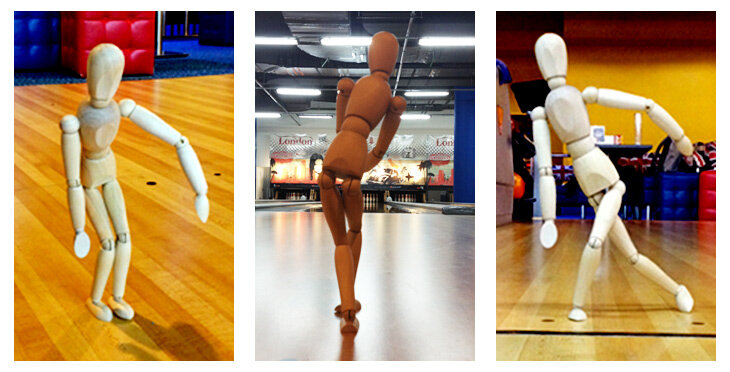

For using this training method, three things are needed: a video of a student’s shot, a video of an equivalent master’s shot (i.e. a bowler with similar physical and mental traits to the student), and a 12 inch tall mannequin, such as one used by art students and sold in stores like IKEA, Hobby Lobby, Michael’s, etc. Examples of the type of mannequins which are effective for this type of training are shown below.

A small artist’s mannequin can be used to demonstrate physical poses during training.

The coach and the student view the video of the student’s shot and discuss the technical elements which are to be worked on.

The coach and the student view the video of the equivalent master shot and, once again, discuss the technical elements.

Using the mannequin, create images of the necessary technical elements.

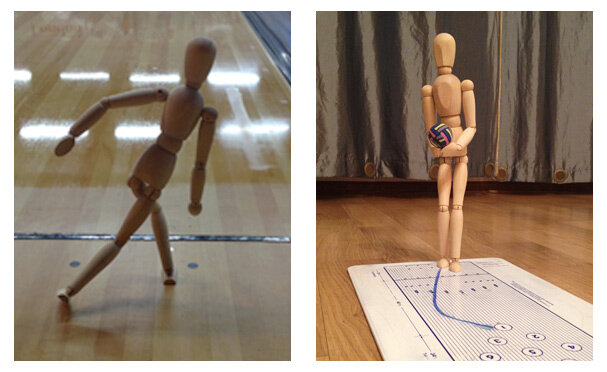

Set the mannequin in the approach area of a lane or on the layout of a bowling lane for a more complete and correct understanding of the player’s position in the space.

At the end of the process, ask the student to mentally reproduce all the movements in sequence.

The mannequin can be used both on-lane and on top of a bowling lane overlay, such as the clipboard overlay shown.

After a while, your students will be able to easily adjust the image of the necessary technical elements in full, and “play” it at will in their imagination. This method is especially effective for young players.

Use of the mannequin during training sessions involving young bowlers is especially effective.

Often, this method of training is not only useful, but it is also is a lot of fun. Give it a try in your own coaching sessions and see for yourself!

Jedi Bowling: Line-of-sight construction skill and the methods of its training

Originally published in Bowling This Month

“Skill” is the ability to carry out an action automatically without active conscious control. An indicator of skill competence is performance of an action without the need to consciously think about how the action will be performed. When a person has skill competence for a given task, it is no longer necessary to think about the execution of the skill via its separate partial sub-operations.

Successful bowling, of course, requires competence in countless complex skills. One of the many jobs of the bowling coach is to develop and use the most effective methods of skill training on our students so that their learning processes can be accelerated as much as possible.

In this article, I want to analyze the process of learning and the implementation of one specific bowling game skill. Namely, we will examine the line-of-sight construction skill of the bowler. Line-of-sight construction is a skill that allows the bowler to envision the launch trajectory of the bowling ball on the lane. We’ll start with some background and with a description of why this skill (as well as other similar skills) can be so challenging to teach. Finally, we will give an example of a new method of line-of-sight training that I’ve been using successfully with my own students to accelerate their development.

Background and motivations

Throughout my career as a bowling coach, I’ve had the opportunity to work with a wide variety of bowlers. This includes players at the novice level all the way up to the national team level.

Additionally, I have a significant amount of experience coaching deaf bowlers. One of my students is a medalist in the Deaflympics and numerous of my other deaf students are European Bowling Championship winners. Recently, one of my female deaf students won a Gold medal at the 3rd World Deaf Bowling Championships in Bologna, Italy in August 2015.

Working with bowlers who have different types of thinking skills has motivated me to seek out improved teaching methodologies for our sport. The task of building an efficient training process for deaf bowlers, for example, has been very non-trivial. This led me to deeply analyze the process of bowling skill learning from the perspectives of cognitive and educational psychology.

This process uncovered psychological regularities of the bowling training process. Developing an understanding of these regularities has resulted in me adjusting my training methods for improved efficiency. This has led to significant accelerations in skill mastery for players of all types.

Line-of-sight construction is one particular bowling skill that can be challenging to teach to both deaf bowlers and many non-deaf bowlers alike. Let’s start by taking a close look at this skill and the current methods of its teaching.

Line-of-sight construction: one of bowling’s fundamental skills

Bowling is a complex skill that involves perceptual, intellectual, and motor abilities of the player. In these ways, it is quite similar to other complex skills, such as learning to control an aircraft, for example. The ability to:

construct motion paths,

control physical efforts,

feel position in space,

make quick decisions about the current situation,

perform standard operations, and

know and apply correctly a set of rules

All are features of both bowling and controlling an aircraft. Many complex activities in a wide variety of disciplines share these same characteristics.

In bowling, line-of-sight construction is an important skill related to targeting that must be developed by bowlers of all levels. This skill is chosen as an illustration due to its importance in the overall structure of the bowling training process.

The ability to envision the line-of-sight on the lane, to keep it in the mind during the bowling approach, and to subsequently analyze the delivery with respect to the line-of-sight allows the bowler to effectively solve a wide range of tasks, such as:

positioning himself in space and correctly performing the physical game elements relative to the given line;

making a correct analysis of the accuracy of a delivery and of the dynamic characteristics of the ball motion on the lane;

making decisions on the necessary changes in ball trajectory and then rapidly implement them;

and much more!

Thus, the described skill of line-of-sight construction is one of the basic skills of our sport. The degree of its mastery defines the speed of a player successfully training the rest of the skills of bowling. It can be an indicator of his success as a whole on the lanes. In fact, the development of this skill is one of the first tasks facing a coach while training a new player in our sport.

Bowler skill level vs. line-of-sight construction skill mastery level

While preparing this article, I have performed testing of bowling players on their mastery of line-of-sight construction skill and found correlations between the players’ success on the lanes and the extent to which they’ve mastered this skill. Here are some brief details of the results of this study:

Entry-level bowlers: Often cannot imagine and describe in words the ball trajectory on the lane; are not visually concentrating on the point of sight during delivery preparation and execution; often use hitting the pins as an accuracy criterion; have no clear image of the line-of-sight.

Mid-level bowlers: Can describe in words the ball trajectory on the lane; are concentrated on the point of sight (sometimes excessively) during delivery preparation and execution; use assessment of hitting the point of sight as an accuracy criterion; the line-of-sight image is in the forming stage.

Advanced bowlers: Can describe the ball trajectory with precise detail in any area of the lane; are concentrated on the line-of-sight duringdelivery preparation and execution, with the ability to change the visual concentration to various points of sight along the line; use assessment of hitting the line-of-sight as an accuracy criterion detailed in various zones of the lane; the image of the line of sight is clearly formed in the visual imagination of the player and is used with no effort during delivery preparation and execution.

As the results of this test show, there is significant correlation between overall bowler skill level and line-of-sight construction skill level.

Current methods of line-of-sight skill training

All existing targeting systems in bowling are built on the principle of line-of-sight construction on the lane. Differences in targeting systems are only in using different markers as the coordinate system for the line of throw construction (targets, pins, breakpoints, exit points, laydown points, starting position of the player, and so on). The final aim of all systems is a line construction on the lane surface and in the approach area.

Operating with initial data in accordance with the theory of the throw line construction voiced by the coach, the player must use abstract logical, spatial, and visual imagination to construct the throw line on the lane and in the approach area. The player must then hold his concentration to perform a delivery, controlling his own movements and the subsequent movement of the ball relative to this imagined line.

If it is necessary to change the ball trajectory, the player (using information provided by the coach) must recalculate the coordinates of the required markers and construct a new line. This is not an easy task. The main problem is in the constant interaction of abstract logical and visual representation types of thinking.

Even when a player is given initial information in the form of visual images and tips from his coach, the transfer of these images to the real lane is always performed in the mind of the player. In such a case, it is impossible to avoid the process of personal interpretation.

Solving this problem, we are increasingly becoming dependent on the features and level of a player’s abstract logical thinking and the abilities of his mental apparatus regarding the interpretation and transferring of the abstract logical concepts into symbols and images used by visual and representation thinking.

If the player is talented in this respect, we get the correct image in his mind and we get it very rapidly. For other players, perhaps even those who are more gifted in physical and coordination abilities, this task may be very difficult. It may either take a long time to perform, or it may not even be solved at all.

“So what?” you might object to me. “Successful bowling is about survival of the fittest; the most talented players will succeed and thrive!”

In my opinion, the difficulty of solving this problem for the player is not so much due to the level of the player’s ability. Instead, the difficulty is caused by the method of supplying the initial information and the proposed algorithms of solution. Too large of a role of abstract and logical thinking in the described processes can be destructive.

We as bowling coaches are a lot like a teacher who tries to solve the problem of constructing and fixing in a pupil’s visual memory the image of a 90 degree angle. Doing this using only a verbal description is quite difficult. Even if the teacher is permitted to draw two randomly-arranged straight line segments and then explain in words how to form a 90 degree angle from them, it is still an incredibly difficult task.

Alternatively, just draw two perpendicular lines, show the angle, and then add any verbal description for better understanding. The result is instant and the student immediately understands the concept of a 90 degree angle!

A proposed new technique for bowling line-of-sight construction training

I will now introduce a new method of line-of-sight construction training that I have used with great success with many of my students. The method involves using a device to create and consolidate in the spatial and visual imagination and in the memory of the player a bright image of the line-of-sight in the real playing environment during delivery preparation and execution.

While training using this device, there is no need to describe the line image using objects of abstract logical thinking, and, as a consequence, there is no need for any interpretation by the player.

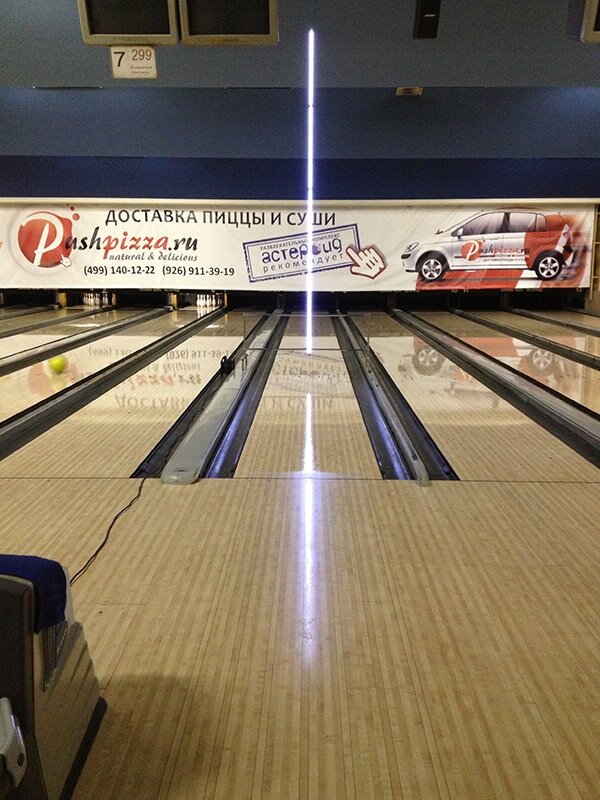

This patent-pending device utilizes a luminous bar (3 to 5 meters high) installed above the lane in a vertical position. Depending on the particular training task, it can be installed in the targeting area, at the exit point, at the breakpoint, or as close as possible to pins. Reflection of this bar creates a bright and clearly visible image of the line-of-sight on the lane. This bright reflected line on the lane is used to train and consolidate the required skill of constructing the line-of-sight by the bowler.

Lighted bar, installed in the breakpoint zone

The property of the reflected line to change its position while the player moves left and right, as well as the possibility to change the initial position of the device, allows the bowler to almost intuitively understand the process of adjusting the line position on the lane.

Since this training technique so directly demonstrates the concept of line-of-sight and its fundamental properties, it is even effective on players who haven’t yet developed advanced abstract logical thinking abilities, such as children.

Here, the lighted bar is installed at the arrow zone for the purposes of 3-6-9 training.

Besides the basic training function of teaching a bowler how to construct the line-of-sight, use of this device has generated four important additional benefits:

Hitting or nearly hitting the line visible by the player is only possible with correct technical throw execution.

The possibility to assess visually the dynamics of the line-of-sight movement along the lane by the player during the delivery creates conditions for more effective correction and monitoring of the spatial and technical elements of the approach. This creates a very effective instant feedback system for the bowler.

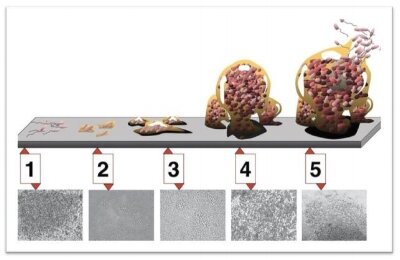

It becomes possible to see a diagram of oil application on the lane and its variations, because due to different oil amounts in different areas of the lane, the reflection coefficient of the light source varies. As a result, the thickness of the oil in different zones and the dynamics of its changes during play become visible to the bowler.

The reflected light line creates the possibility of performing a visual assessment of lane topography. The curvature of the reflected line shows the deviation of the lane plane from the horizontal plane.

Here are some additional videos of the lighted bar in use during training, both as viewed from the coach’s position behind the approach and as viewed through the eyes of the bowler.

Results

The practical use of this technique has shown that it has high efficiency. The image of the line-of-sight is quickly fixed in the visual memory of the player. After just a few training deliveries, it is not difficult for most players to use this image, even in the absence of the training device.

Mastering the line-of-sight construction skill has become much faster. Testing has shown that the time duration of mastering this important skill is reduced significantly (sometimes by an order of magnitude) through the use of this device and this training method. Additionally, the skill is successfully mastered by players regardless of the development of their abstract logical and visual representation thinking.

Often, after a month of training using this technique, entry-level players show a skill mastery level comparable to that of advanced players. This allows them to progress more quickly in their future training.

Practical considerations and next steps

Some of you might be wondering about the practicality of the above-described training method. It is true that it does require some special equipment. Also, like all things that happen beyond the foul line, use of such equipment requires agreement and cooperation with the bowling center owner.

As of now, there is no commercially-available “off-the-shelf” luminous bar line-of-sight training system. However, it is a fairly simple design that can be constructed from components that are readily available. It can be installed on the lane in about five minutes and removed in three minutes. Also, I have built and used a version of this system that is fully portable. Development of a ready-made system that can be purchased by coaches is a possibility for the future.

Conclusions

I hope you have enjoyed this introduction to some of the challenges in bowling skill training and that I have opened your eyes to the opportunities that exist in developing more efficient training methods for our sport. As previously mentioned, I have studied the theory of effective learning and skill development for bowling extensively. I have many other ideas in different areas of bowling skill development, such as timing training, swing direction training, ball reaction understanding, and more. I hope to share them with you in upcoming articles.

Finally, I welcome your questions, comments, and suggestions, as they will be very beneficial in helping me decide on content for future contributions.

Entry Angle Assessment

Originally published in Bowling This Month - February 2016

In modern bowling, a player’s success depends on the implementation of numerous components: throw execution, ability to measure the characteristics of ball motion, mental and psychological preparedness, and much more. In this article, I want to share my experience in teaching the skill of determining the bowling ball’s entry angle. Mastering this skill allows the player to quantitatively assess one of the major characteristics of ball motion and enables deliberate correction of numerous game components.

In this skill, as well as the line-of-sight construction skill (described in my previous article), visual and spatial thinking are critical. We have to pay the most attention to these types of thinking when learning and using both line-of-sight construction and entry angle assessment skills. When testing players at different levels, most players, including advanced ones, could not determine the value of their ball’s entry angle. In the majority of cases, they could provide only a simple and ambiguous description, such as small, large, insufficient, bad, too much, etc.

This is not surprising, since very few players have had the opportunity to assess this parameter using the currently-available technical feedback systems that provide entry angle data (such as CATS and others). In practice, the skill of entry angle determination is almost always developed over many years of training and long tournament practice. On the other hand, applying the training methods described below, it is possible to obtain improved results in significantly less time, wherein players, using their spatial and visual thinking and memory, are able to determine the entry angle quantitatively using a range from 3 to 6 degrees.

When we evaluate trajectory accuracy characteristics, the lane markings (counting of boards and/or targets) allow us to see and quantitatively assess the ball’s lateral position in different parts of the lane (target area, breakpoint area, position of the ball at pin contact, etc.). This allows us to literally name the number of a board on which the ball is positioned at any given point along its trajectory. For example, when we need to draw the line-of-sight, we can use readily visible marks, such as targets, pins, dots, etc. In contrast, it is difficult to determine the entry angle on the lane due to the absence of readily visible and memorable orienting points.

Laser line projection

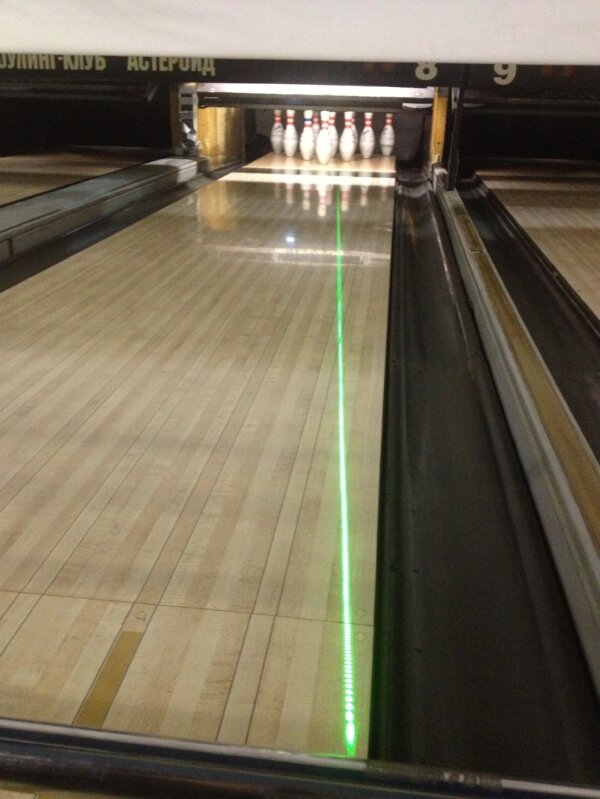

To overcome this lack of orienting points, the student first and foremost needs to be shown the image of the entry angle line on the lane and how the entry angle is determined. For this purpose, a special line laser can be used to “draw” the entry angle line on the lane.

An entry angle line of 5 degrees “drawn” onto the lane with a green line laser.

During the initial training phase, it is important that the student does not focus on the entry angle value. It is most important for the student to see the image of the entry angle line on the lane and memorize that image. A good starting point is to mark the angle at 4 degrees and ask the player how the entry angle of his throw differed from the visible one on the lane.

A powerful memorization technique is for the coach to quickly move the visible entry angle line to reflect the characteristics of the specific player’s throw in order for the ball to pass along the visible line as often as possible. Thus, the player will quickly learn to determine the presence or absence of ball roll as well as the length of the ball roll. This is a very important and useful intermediate skill!

Editor’s note

Laser setup example

The laser line in the above image was generated using a standard off-the-shelf 350 mW green laser pointer in conjunction with an off-the-shelf line lens kit, with the laser mounted on a tripod, as shown.

Please be advised that lasers can be dangerous. A 350 mW laser is a Class 3B laser device which can cause harm if used improperly. Among other risks, never look directly into the beam of a laser and never point a laser beam at a person. Never use a laser unless you are properly trained and understand all the possible risks. Also, please keep in mind that the sale and use of lasers can sometimes be subject to government regulations.

It doesn’t take long for the student to memorize the entry angle image when using a bright and memorable laser line. Once the player fully understands these concepts, the next step is to learn how this line ties into a coordinate system which provides the framework to make the necessary quantitative assessment to determine the angle value correctly in the absence of the laser line. There are two very helpful methods for this purpose.

Intervals

The first one is the method of intervals. With this method, the player is taught to quickly analyze and determine various lengths on the lane correctly. In principle, this skill is very important for understating ball reaction.

The goal is for the student to memorize the most important intervals on a lane, including 30 feet, 35 feet, 40 feet, 45 feet, and 50 feet. We approach this task by placing memorable marks, such as paper taped in the gutter, at the desired length or lengths.

An example of using paper markers in the gutter to show the location of specific distances.

An example of using paper markers in the gutter to show the location of specific distance. Of course, this is assuming that the player understands basic lane geometry (such as the width of lane, the distance to the targets and pins, etc.), since memorizing the desired unmarked points requires that the student use all available visual cues. For instance, the 1st pin (at 60 feet) has a reflection that can either correspond to or be very close to one of the desired intervals (50 feet for a taller person, down to 45 feet for a shorter person). Determine what interval the bowler sees and use it.

It is important to understand that the intervals are determined by the individual’s unique characteristics, since they are connected with the player’s height and the height of his eyes in the initial and finish positions. To begin with, focus on memorizing the required intervals from the player’s finish position, as it is critical to choose a consistent and repeatable position from which to memorize visual cues. Moreover, this is yet another argument for the benefit of a stable and proper finish position. Obtaining visual information after releasing the ball from the foul line is facilitated by correct and consistent technical execution.

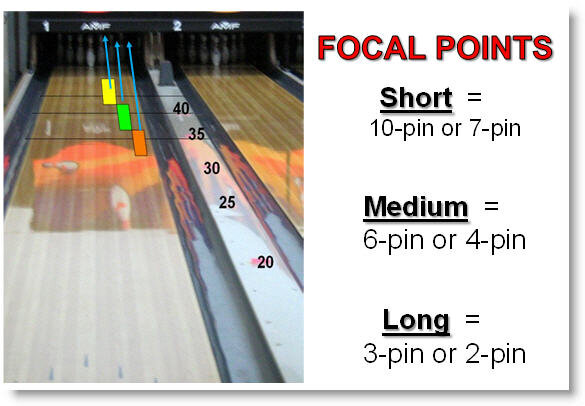

For entry angle determination, memorizing just the two lengths of 30 feet (half the distance from the foul line to the first pin – 1/2 of the lane) and 45 feet (half the distance from the 30 feet mark to the first pin – 3/4 of the lane) is enough. It is easiest to start by memorizing the 30 feet mark and then later adding the 45 feet mark. Once the student has memorized these intervals, the next training session can focus on learning how these lengths relate to the two entry angles of 3 degrees and 5 degrees.

Ideally, using two laser lines, the coach should indicate the 3 degree line extending from 31 feet to the pocket and the 5 degree line from 42.5 feet to the pocket. Remembering the memorized visual cues for 30 and 45 feet, the student can simply add 1 foot for the 3 degree line and subtract 2.5 feet for the 5 degree line in order to commit these angles to memory.

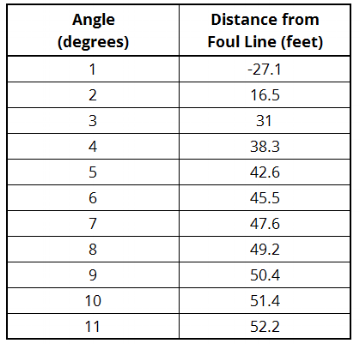

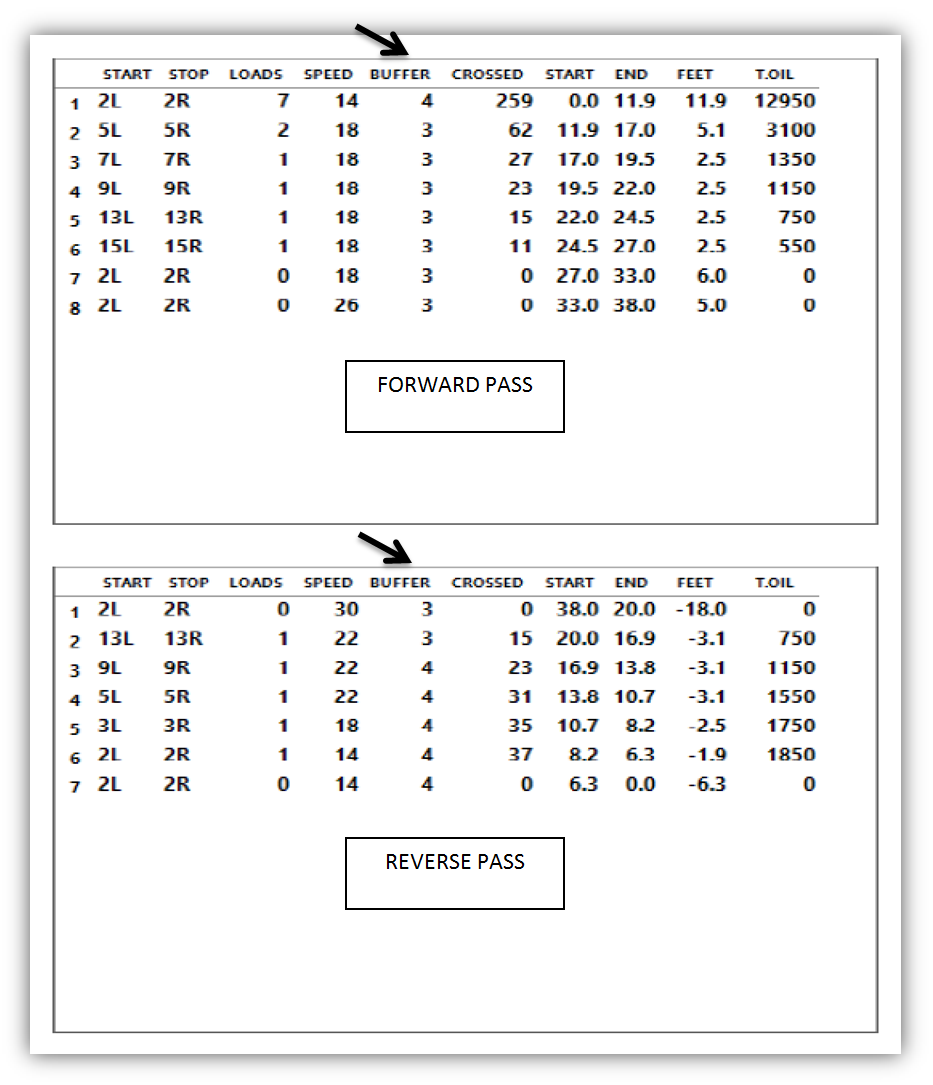

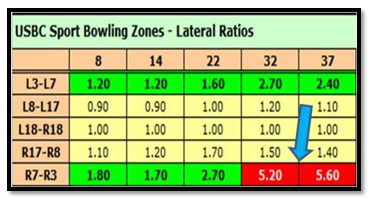

In order to achieve different entry angles, balls and throw execution parameters (speed of throw, axis tilt, ball trajectory, etc.) can be changed. The table below shows the entry angle which corresponds to the given length of the lane edge from the foul line.

Angle vs. distance for a line drawn from the gutter edge to the pocket.

At this point, the student has learned a significant and complex skill set: a practical understanding of the detailed range of his ball arsenal and the effect of changing throw characteristics on the ball trajectory.

The use of a device for marking the aiming line, described in my previous article, in combination with marking the entry angle line(s), is an efficient technique for teaching the player to consolidate these skills.

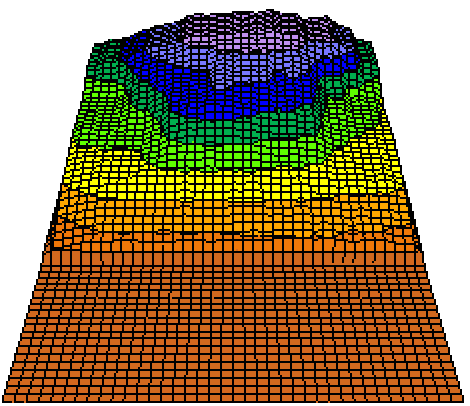

Retinal angle assessment

For further consolidation of this newly acquired skill, there is another approach to memorizing the entry angles that a player sees. Have you ever asked a beginning student or spectator about the entry angle value they perceive? The answer is consistently 45 degrees. This is accurate if the angle is assessed as obtained by the retina at the foul line. It matches the angle measured on video or photos.

A bowler’s perception of entry angle is typically very large (shown from a height of 4.5 feet at the foul line).

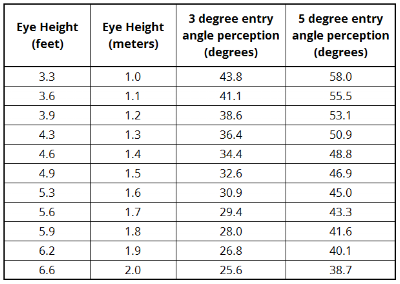

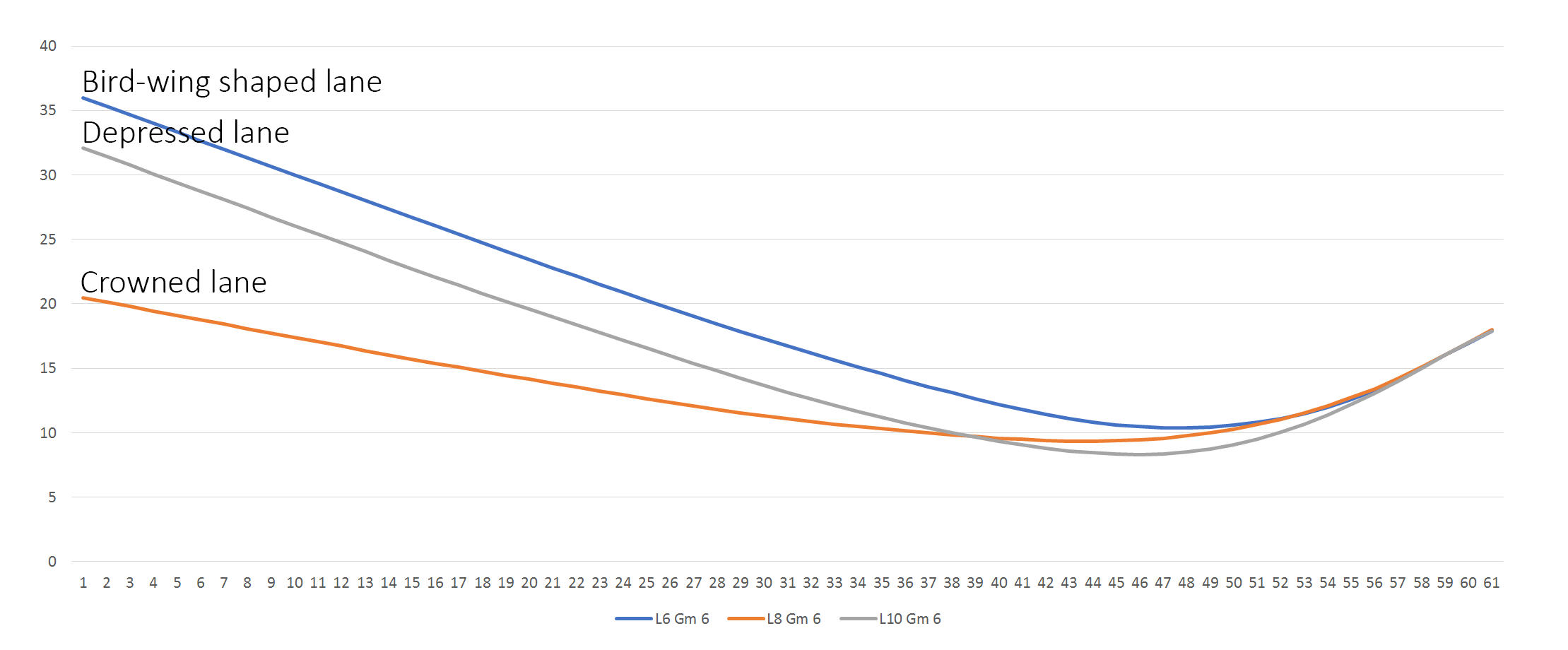

Retinal angle assessment can be used to obtain the true angle. In order to do this, the coach must determine the characteristics of the player that will influence their perception of the entry angle. The table below shows the height of the player’s eyes at the finish position which corresponds to their perception of 3 degrees and 5 degrees.

Entry angle perception (retinal angle) from the bowler’s perspective vs. height.

In applying this assessment method, the difference between these two angles (3 degrees and 5 degrees) as viewed by the bowler is approximately 15 degrees. For example, if the height of the eye is 1.6 meters (5.3 feet), the angle of 3 degrees is perceived as 31 degrees and the angle of 5 degrees as 45 degrees. These angles are fairly easy to remember. Simply measure the height of the player’s eyes at the finish position and print the respective angles for memorization.

Finally, once the player has fully understood the entry angles of 3 degrees and 5 degrees, he can extrapolate from there to additional angles. For instance, knowing 3 degrees and 5 degrees, the player can easily see when the ball’s trajectory is between these memorized points and determine the angle to be 4 degrees. Equally an angle less than 3 degrees would be 2 degrees or slightly more than 5 degrees is 6 degrees. The ability of the player to determine the range of angles helps him assess the situation on the lane and ultimately provides the tools to consistently obtain the ideal entry angle during competition.

New Product Lifecycle

Have you ever wondered about the process of creating a new conditioner? How do we test? What do we look for when we’re testing? How do we choose test centers? How does field testing work? If you’ve ever wondered about the research and development process, or if you’ve ever thought you might like to be a test center for a new product, keep reading.

Creating a new conditioner is a lot like baking a cake without a recipe; you know how you want the cake to look and taste and you know you’ll need some flour and sugar. But, you don’t have an actual recipe so you have to figure out the rest of the necessary ingredients in order to get to the desired result.

Creating a lane conditioner can follow that same concept. In general, mineral oil is the “base” so we’ll likely use some combination of mineral oils to start. After that, we experiment with different combinations of chemicals to try to achieve the results we want to see. Since we’ve been in the lane conditioner business for quite some time, we have a solid foundation of knowledge of many raw materials. We know that some materials will give us more “slickness” while other materials may help the conditioner be “hookier”. We constantly search for new technologies to help us create the best lane conditioner we can.

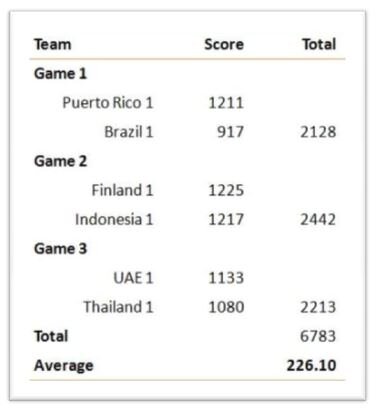

Once we have a formula, we start testing. For lane testing, we generally use a house pattern and we’ll use the same house pattern throughout testing so that we have an equal comparison when we make formula adjustments. We are fortunate to not only have our Batch Test bowlers, but some extremely talented bowlers throughout our building. So, we take full advantage and use them when we’re testing a new product. We try to use a variety of bowlers so that we can see how the conditioner performs for bowlers of different styles. And, as much as possible, we try to use the same set of bowlers throughout a product test. While they’re bowling, we’ll track scoring, bowler moves, and we’ll make notes on things like ball reaction, residue on the bowling balls, and carry down.

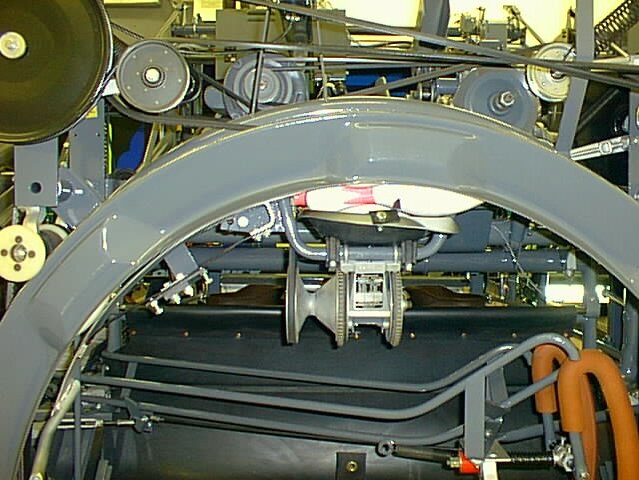

In the lab, we’ll test physical properties like viscosity, density, and surface tension. These properties give us some general characteristics about the conditioner like how it might flow on a lane. We also do temperature stability testing. We’ll put samples through freeze/thaw cycles to see if the conditioner is impacted by cold and we’ll do heat ramp studies to see if the heat negatively impacts the conditioner. We even do chemical compatibility studies. Belts and other materials from pinsetters, tubing and other parts from lane machines, and other materials that could contact the conditioner are cut into pieces and soaked in the conditioner as well as in some of the raw materials. We measure the parts before we soak them and then measure them again after one month. This helps us determine if the chemicals will create any issues with the parts.

The next phase of testing for a conditioner is field testing. Initially, we’ll test in one or two centers to make sure the product will perform well. We work with the centers to understand what they see from the conditioner using their normal pattern and maintenance routines. They provide feedback and we work together with them to make pattern adjustments, machine adjustments, and such to try to improve the performance. We track all of these changes and use the information to determine if we need to make adjustments to the product. If we make adjustments, we continue testing until we get to the point where we feel confident that we’ve created a viable product.

Next, we continue adding centers to our field test. Ultimately, we like to have at least 15 centers test a product for several months. We try to cover as many different variables as possible by using centers all over the country. By testing on different lane surfaces, pinsetters, ball returns, and so forth, we can determine if the conditioner will be a good fit for different combinations and in different environments.

While the product is in field testing, we continue collecting data in lab testing. We send samples to partner labs for analytical testing like flash point and fire point testing. These tests allow us to determine proper packaging and shipping requirements. We also submit a sample to USBC for approval. In order to gain USBC approval, a lane conditioner must meet the required specifications for viscosity and UV content.

As we continue with field testing, we keep notes on pattern adjustments made by each center. This helps us learn what works; and, more importantly, what doesn’t; with patterns on different surfaces. We use this information once a product is released to the market so that we can give our customers educated adjustments for their patterns when they switch. What that means is you can switch with a little less trial and error and a few less irate bowlers.

Just before we release a product to market, we build all of our marketing and sales materials. We use information we gathered from our field testers and data we collected during our various phases of testing. We conduct in-house training for our Techs, Customer Service, and Sales staff. And, we start making batches in preparation for sample kits. Our goal is to release the conditioner to the market in the summer so that your center has time to try it and fine tune your pattern before your fall leagues start again.

Now, all this may sound glamorous, but many of our test centers would likely tell you that testing isn’t always rainbows and butterflies. It can get ugly and you certainly have to be willing to make your bowlers angry. When we send a center a new product, we request that the center try the product without making any changes to their normal procedures and pattern. So, if a center had been using a conditioner that was characteristically hookier, and we asked them to use a conditioner that is slicker, the bowlers would see something different than what they’re used to seeing. And, if scores go down, it could make for some pretty angry customers. Test centers can’t be reactive to that though. We need centers who can give us quality feedback and that are willing to make the adjustments we suggest based on their feedback. We need centers that will work with us as we work through issues and try to improve the situation. It can take some time to fine tune the adjustments and we need centers that are not going to throw in the towel while we work through the chaos. The rainbows and butterflies come when we get the right adjustments and scores go up and bowlers comment about not moving as much during a league session. Being a test center can be as frustrating as it can be rewarding.

We do our best to create products that solve a problem or fill a need in the industry. The process takes a lot of time and it involves a lot of people. If we didn’t have customers to give us valuable feedback and we didn’t have test centers we could trust to help us during the development process, we wouldn’t be able to create solid products. We count on our customers to tell us what they think and even what they need as we continue to create products to improve the bowling experience.

If you’ve made it this far and still think being a Kegel test center sounds pretty darn awesome, you can reach out to our Kegel team to see if you qualify. You can also fill out our Test Center Information Form so we can gather all of your center specifics.

You just push the button...right?

As I sit in the back of another bowling center, maintaining lanes for another tournament, I have been thinking about that famous line above, partially because I have already heard it at least once today. There are so many stories…some funny, not so funny, and some downright scary if you were in my shoes. I thought a glimpse of what we do behind the scenes could be an eye opener for many. Making things run smooth through chaos can be our biggest attribute sometimes.

The tournament I am currently at is a great example of the time put in outside of actually running lanes. Starting with a flight across the Atlantic and getting off the plane as first light breaks in Europe, which can be OK for those that can sleep on planes. My mind before an event however, runs 100 MPH, so that never happens. Explaining the Lane Mapper to the agent withholding it in luggage was easy THIS trip…first hurdle.

After arriving at the bowling center and plugging in my batteries for the mapper, I realize the charger isn’t working. The adapter that I brought is not converting voltage properly, so a quick google search of local hardware stores and off I go, many Euro’s later, we are in business. I finished mapping half the house around 4pm local time, just in time to head back to the hotel to find there was a new windows update pushed out that wouldn’t allow the PDA from the mapper to connect to the computer. Hacking windows registries until almost midnight and that problem is solved. The bowlers will be happy; they can have their lane map, barring nothing else tries to get in my way.

Arriving the following morning, or same morning if you like semantics, the mapping is finished. Setup the machines, run all the tests and calibrations, study the maps, pick a pattern. Out by 5:00pm, it’s a good day!!!!

Once the tournament starts, it’s the normal day to day obstacles, bowlers take more time than anticipated and we run two machines and catch things up so squads start on time. In 11 days I will be back in the US to start all over again. No rest for the weary.

Thinking of previous events as well, it’s normally not the machines that we deal with when we have problems. I remember going to a major event and doing a test clean on the first set of lanes for testing. I honestly thought something was wrong with my machine. I ran the second machine I had with me and saw the lanes had the same look as the first I did a strip only on.

At first I thought the lanes had a delamination problem, but upon further inspection, there was a film on the lanes from 10-10 that I couldn’t pull up. I scratched it with my finger nail and was able to remove it, but the lane machine would not. Running down the list of things to do. I tried straight cleaner with a rag by hand, that didn’t work. IPA with a rag by hand, two strikes. I don’t like to strike out, so it was time to call the chemical engineer back at the office!

After a few pictures, and a lengthy conversation, she asks me to grab some vinegar from the snack bar. We let it sit on the lane for a few minutes and to my surprise, the film came right off. This means I needed a mild acid based cleaner to clean the lanes and remove the film. Not wanting to hurt the lane bed itself, we found a cleaner that would work from a local hardware store with a little more “potency”, and another problem is solved for the day. Granted I returned to the hotel smelling like a fresh pickle from using the vinegar as a test, but the bowlers would be happy at the end of the day so it was worth the trouble.

During the PWBA tour, I was at an event with one of the most attentive staff I had worked with in quite some time, which saved me from a disaster believe it or not. We had been charging the machines on the far side of the building for testing, and the first day of open practice. No issues all week and it was smooth sailing. I walk into the center after going to get breakfast and one of the staff pulls me aside and says they had moved some things around for my machines.

Apparently, they had some electrical work done earlier in the year for a renovation, and the water heater on the OTHER side of the building was tied to the outlet I had plugged my machines into. They never knew it, nor did I, and it hadn’t been an issue until the center was full of people going to the bathroom and washing their hands making the water heater turn on and ultimately tripping the breaker I had my machines plugged into. They happen to notice that the lights on my charger had gone out and started to investigate on their own. I guess their attentiveness was good on three fronts. They know what the water heater is linked to, people had hot water to wash their hands, and my machines got charged and didn’t die 4 lanes before I finished in the middle of a tournament. Kudos to them for saving me on that one.

What came out that example was a lesson learned, and I now carry a tester for loads and outlets that I use when I go to bowling centers. I had to laugh out loud as I typed that last line. A little known fact is a lot of the upgrades or changes that happen to machines come from the fact that we experience things in the field and want to make them better for the end user. Automatic shut offs after a certain period of time on battery operated machines, suction cups on drip pads, redesigns of certain parts, and numerous software changes based on scenarios we encounter just to name a few.

Lastly, as most know, Kegel provides lane maintenance for a multitude of tournaments, but JR Gold is the most brutal workout a lane technician can go through. No problems have occurred at this event over the years that are worth writing about, but just to give you an idea of the schedule we maintain; seven days of up at 3:30am, pushing the button by 4:30am, and staying at the bowl until 8:30pm through multiple re-oils. We provided 4 of the 8 lane technicians, 16 brand new machines, did almost 14,000 lanes, and we also provided and went through over 50 cases of oil and cleaner. This is equivalent to what a 40 lane bowling center does in 1 year in a week!!! Not to mention the 200+ lane tapes that were read over the course of the week.

Even through all of this, we answer questions for customers that may be at the centers with their children, do our paperwork and answer emails between squads; it is truly non-stop for a solid week. We would not however, have it any other way.

I can only hope that this small glimpse of what one lane technician has experienced over the years, will allow you to appreciate what we do. When my career is over, I could probably write a tell-all book that wouldn’t sell more than 10 copies but would be 200 pages long and one heck of a funny read for anyone in the business.

It all leads to one bottom line, we take pride in what we do, the builders in manufacturing take pride in what they do, and at the end of the day we all try to make things look seamless. Hearing the statement “you just push the button” is actually a compliment. If you walk into the bowling center and see me wrapping up lanes for a tournament and you can say, “You have it made, all you have to do is push a button”, then I have done my job well.

Have you hugged your mechanic today?

A recent topic on a bowling technician website caught my attention. It was posted by a proprietor wanting to know why he could not find a mechanic for his center. Bowltech.com is visited by some of the best techs from around the world as well as several manufacturers. The gentleman had been trying to hire a mechanic for the past three years with hardly a nibble.

After posting his compensation package, he was still in a quandary as to why good mechanics are so hard to find. Several members of the bulletin board responded that many topnotch techs were lured or forced to seek maintenance positions outside the bowling industry. Others were very happy staying where they were, having growing families and roots in the area. A few even felt that they had been driven out of the bowling industry by management that treated them as "second class citizens".

Money is a consideration - a good tech can be worth $20-30 per hour - and many are doing the job with little or no benefits. To many techs, the work environment is also an important consideration. A number of techs I talked to said that they felt as though they were being isolated from the rest of the employees.

Having spent over 25 years as a mechanic, I am sympathetic with both the proprietor and the maintenance people. Hiring a head maintenance technician can be one of the toughest things an owner has to do. Starting a new position can also be stressful for a head mechanic. Hopefully, with the suggestions that follow, everyone's life can be a little easier.

What to look for and where to look

Working on bowling equipment is a highly specialized occupation and is probably the least respected as far as the industry goes as a whole. It has evolved to the point where the tech is expected to not only work on the pinsetting equipment, its peripherals, and maintain high scoring lanes, but also must be a computer whiz, a plumber, carpenter, an electrician, an appliance repairman, and an inventory specialist. In some centers he must drill bowling balls and in the same day, help in the snack bar.

The head mechanic is on call anytime the center is open (most are open about 18 hours a day) and is expected to come in and do repairs on weekends and evenings. Many work for long weeks during state and national tournaments without a day off. He is in charge of his night and weekend employees and therefor needs to have some "people skills." These skills are applied when dealing with customers as well. Meetings regarding employee relations should include your head technician

When searching out a candidate for your position, you should decide how much experience is desired. Longevity in the bowling industry can be a sign capability. Seasoned veterans are going to be rarer to find and will also be harder to woo away from their current locations.

Many of the large chain operations promote from within their own companies, moving techs through their training programs towards the goal of placing them in company centers. Some of these younger mechanics have great attitudes and are more likely to be open to the idea of relocation. The hunt for a new key employee should start with ads placed in the trade magazines and the numerous job related websites.

After reviewing the current crop of ads, I noticed most ads for managers were well written. These ads used colorful words and conveyed a feeling of excitement. Most ads for mechanics seemed dull, with little more than a stark description of the position. The use of descriptive language with a more detailed explanation of the position being offered can make your ad stand out. Word of mouth can also bring you results.

Contact bowling suppliers in your area. These distribution centers have contact with mechanics from around the country, and can get the word out to bowling world about your vacancy. Also, do not discount technicians from outside the United States. Some outstanding mechanics live overseas and might be willing to make a big location change. Be sure to include your e-mail address in your ad. This will make responding much easier for those who are not in your immediate area.

Once you begin to receive responses to an ad, take the time to check references. A well written resume with job history is an important tool in determining the viability of the prospective employee. Skills that are listed on the resume can also give you an idea of what you can expect out of an individual.

If a desired attribute is missing, you must determine if the individual is worthy of the cost of additional training. Many colleges offer night and weekend classes in fields that can be helpful to the bowling center. These classes can add to the value of the mechanic and in the long run, save a center a substantial amount of money. Heating, ventilation, and air conditioning classes and clinics are offered by some manufacturers. Welding and electronic classes are available at most Vo-Tech schools.

In some specialized centers, such as military and casino operations; the mechanic has the luxury of a staff of other professionals who will take care of the various areas of the building. This leaves him with the bowling operation to maintain. Even in these centers, the head mechanic should have a rudimentary knowledge of facility maintenance on his resume.

What to offer

A good package of benefits can assist in bringing a quality employee into your organization. Health insurance, profit sharing and retirement can carry a lot of weight when looking for an important addition to the bowling center team. A compensation package that includes assistance with relocation costs is a big plus. Moving a new employee and family across the country is an expensive proposition. Hourly versus salary is something that should be discussed. This issue can be extremely sensitive and should not have any "gray areas" regarding overtime or extra compensation for extra work accomplished.

Contacting other centers and non-bowling facilities can give you valuable insight regarding pay and benefits. Check with hospitals, bakeries and manufacturing facilities near you. The engineering departments of these businesses can give insight into what kind of competition you might face in the event of a mechanic leaving your center. Review all of the jobs that will be required of your head maintenance tech, and compensate him accordingly.

Money, however is not everything. Having the tools he needs is another benefit that can bring a good mechanic into the center. A good set of hand tools along with the necessary electric or air equipment can make many repairs easier. In this quickly changing world, some high tech tools are becoming necessary.

Access to a computer and a cell phone is very important. Many technical drawing and wiring diagrams can be emailed directly to a mechanic. Most manufacturers now have websites with support for their products. Bowltech.com and Facebook mechanic pages have a wealth of information for both the beginner and the most experienced mechanic.

Another important tool is continuing education. Most manufacturers offers clinics and seminars year round. A well informed maintenance staff is critical to a center's success.

The ability to manage the budget for the department is another thing many techs feel that they should have control of. When a part or supplies are needed, he should be able to place an order without having to jump through flaming hoops. Many mechanics have abused this freedom and have forced management to take hard stands on spending. Still, an arrangement should be possible without compromising the maintenance of the equipment or the building.

Most long time mechanics share one thing in common...a love for what they do. Not much compares to the feeling of accomplishment they get when they hear the gentle hum of "their" equipment. The head of maintenance in many cases in responsible for millions of dollars’ worth of equipment. The livelihoods of all the employees in the center are directly tied to his ability. The enjoyment and comfort of your customers depend on this "Rodney Dangerfield" of the bowling industry. View him as an important member of management. Provide a set of work uniforms, include him in decisions and give him "some respect."

Finding the right person might take some time, but the search can bring you a true professional, someone who is ready and willing to contribute to the success of your center.

In the Good Old Summertime

As the warmth of spring starts to creep into our thoughts, summer projects come to mind. While they are necessary to keep our machines and lanes maintained in top-notch manner, other priorities need to be addressed for the summer.

The spring months are the perfect time to evaluate any educational opportunities that will arise in the summer. Ongoing training for your staff should be scheduled at this time. Check with bowling distributors in your area. They will have information regarding seminars on lane maintenance and pinsetter maintenance. Ball drilling clinics are often conducted by manufacturers in conjunction with their distribution network.

The slower months of May, June, and July are the perfect time to schedule a training session with Kegel. We offer training on all of our lane maintenance equipment along with classes on lane care. Training sessions on lane machines and lane maintenance can fill quickly and must be reserved in advance. The information from these classes can lead to cleaner, more consistent lane conditions for your bowlers. Maintenance issues can be addressed by the experts and solutions gleaned from their knowledge.

Our state of the art, newly remodeled training center offers coaching from world class instructors using the latest techniques and high tech equipment such as Specto and the Torch.

The major equipment suppliers will hold schools for their specific machinery year round, but the summer sessions are the most popular. Make reservations early for these classes. Sending your mechanic or even a pin chaser to school can pay huge benefits. The knowledge acquired can be put to use immediately at your center.

Bowl Expo is held every year and contains some of the most advanced training available in our industry. From marketing, to maintenance, to new products and services, this is the one event to put on your "must do" list. Send as many of your staff as possible to the classes and seminars.

Over the years, some of the most useful information I have ever learned came from Bowl-expo. And not all of it was from a classroom! The interaction between managers and their peers can lead to impromptu round table discussions that can solve the bowling centers’ worse problems. It is great to know that you are not the only person with a dilemma and others may have already solved it and are willing to share their solution.

The same goes for your mechanic. The center mechanic can gain a tremendous amount of knowledge during a day long clinic, then retire to the lounge and learn even more over a couple of beverages with his cronies. This kind of communication is important; it gives him an insight to the procedures of maintenance personnel from around the country.

Attending the trade show, you can start to build a rapport with a distributor that was just a faceless voice on the other end of the telephone. Take the time to shake hands and say "Hello" to the face that takes the orders that keep your center supplied.

Some participants in the trade show offer discounts for orders placed at the show or within a short time-frame after the show closes. Take advantage of these reduced prices and other specials. They can save you some big bucks! .

The summer can be a great time to start team building. Start a softball team, host a picnic or barbeque. You and your employees just spent 8-9 months indoors and could use some fun outside of a bowling environment.

Reserve a tee time at the local links and have a fun type golf tournament. Have quirky prizes and events. Many times these events can be traded with the golf course staff for a bowling party.

An event like this can be a great way to ensure that the employees that might be laid-off during the summer will be willing to return in September. Your part-time help is often overlooked, and should be included in whatever "end of the season" bash you decided to hold.

The education and well being of your staff should be one of your top concerns. By showing them that you do appreciate their hard work, you will create a loyalty that won't soon fade. Give your employees the schooling they need to do a better job, and both you and they will have an easier time when the leaves start to turn yellow and the snow begins to fly.

Tick Tock Tech Support

“Hello, thank you for calling the technical support line of (Insert company name here). If you have reached this recording, it means you are calling outside of our regular business hours or all of our support staff are helping other customers. At the tone, please leave your name, company name, phone number including area code, your account number; service tag number; make and model of your product, a brief description of your problem, and a member of our support staff will return your call as soon as possible…”

If I had a dollar for every time I have heard something like this recording, I might be able to buy a private island and retire. Not much is more frustrating than having a major problem with a piece of equipment and reaching a recording.

At Kegel however, we do our best to get you to a person by providing emergency tech support 24 hours per day, 7 days a week. With a response time of 30 minutes or less, you can be certain you will have help with your lane maintenance needs.

No matter how old a customer's machine is or what their problem might be, Kegel Tech Support is free for our customers, and we don’t plan on making changes to this policy any time soon. But to ensure we can support you in the most accurate and timely manner, there are some things we may need to ask you.

The information we will ask at the beginning of a tech call are:

Confirmation of the center’s physical address along with updated points of contact, phone numbers, and e-mails.

Lane machine information: type of lane machine, serial number (can be found on the bottom plate), and the version of the PLC thoughtware. This information can let us know what pattern or upgrade possibilities are available for any specific lane machine.

Lane information: wood or synthetics, and if synthetics, what type, plus the age of your lane surface.

Lane chemicals and supplies currently being used: lane conditioner, cleaner, and cleaning cloth.

If you can have this information available before you call tech support, it will help expedite your call, fix your problem quicker, and we greatly appreciate it.

Apart from lane machine tech calls, we get a lot of calls for oil pattern assistance, but telling us that your lanes are “squirrely” or “spotty” doesn’t tell us much – we need specifics in order to help you the best way possible.

For instance:

Do the backends seem to play tight or is there too much backend?

Is there not enough hold area or not enough swing area?

Is the pattern not holding up long enough, and if so, where are the lanes breaking down the quickest? For example; specifically from boards 8-12 from 25-35 feet.

Once you know that information and you call us, make sure you have the following:

What are the pattern numbers in the lane machine? Do you have a KOSI program sheet of your pattern you can quickly e-mail?

What kind of lane surface do you have? If synthetic, what brand, how old, and are the on top of old wood lanes or not? If wood, when was the last cut and re-coat?

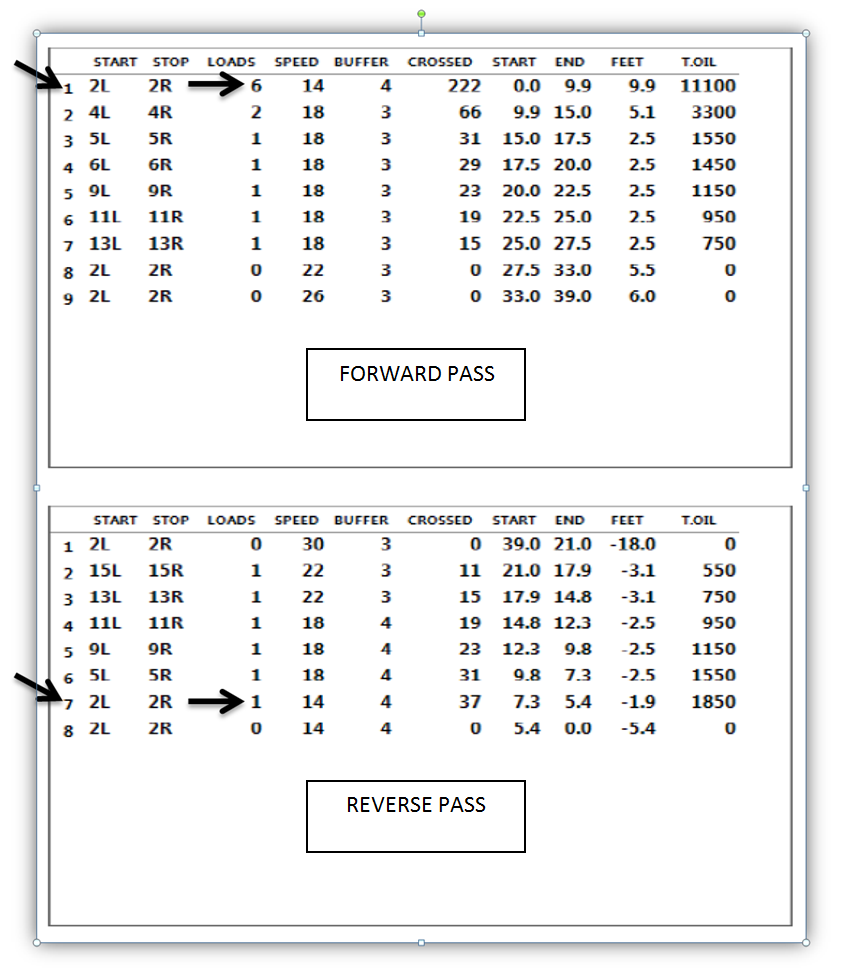

What kind of oil transfer system is in your lane machine – transfer roller, wiper bar, dual transfer brush, or the newest Duo System? Each oil transfer system has its own unique characteristic and oil patterns must be built to complement the system.

If not shown on the program sheet, what is the oil pump set at – 40, 45, or 50 mics?

How many games per lane are you trying to get out of the pattern? Fifteen games per lane (one shift of league play) or more than that?

What kind of oil and cleaner, and what is the dilution ratio of the cleaner?

From this point, the Kegel tech can begin to tweak your oil pattern, or figure out what else might be causing your problems.

what if you have to call another company for support?

While many of the following tips for tech support do not apply to Kegel, they do give advice for tech support calls to companies who might not have a fully staffed tech department on hand.

When we call for support, we want to talk to a real person with an answer to our question, and we want the solution now! Most of the time when we call tech support it’s a crisis breakdown and it must be taken care of post-haste.

So we make our panic-stricken call, and we fall into a mindset that we are the only customer on the planet. We want to get our problem fixed and we want the solution as quickly as possible - we do not want to "leave a message” for the next available tech.

Unknown to us, there may be numerous messages ahead of our own. In our mind we feel that after a couple of minutes, we should be hearing from the support desk. In the real world however, it could take several minutes to receive a call back.

The people working the phones often are helping more than one customer at any one time. They may be trying to walk people through procedures who have no expertise with the equipment - this can be very time consuming.

The number of staffers working the phones can also vary, which can contribute to long wait times for support and call backs. No one can predict the number of calls a tech support desk will get during the course of a day and they are sometimes caught shorthanded.

Another cause for a delay in returning your call might be the fact that you did not give enough information while recording your message - so have all your information ready when you call. Make, model number, part number, and serial numbers are going to be needed. If the tech has to spend time researching what equipment you have, it will add to the time it takes to get your equipment repaired.

Giving a detailed description of the problem and what you have already attempted will help the tech. They can then start the troubleshooting procedure prior to calling you back. This can help you get operational faster.

Patience is needed when waiting for a call back from the support desk. While waiting, try to troubleshoot the problem yourself. Sometimes a solution to the problem becomes apparent after a few minutes away from the afflicted equipment.

When you finally receive that call back from the support desk, take notes! Do not rely on your memory to be able to recall a long sequence of troubleshooting procedures. Note whom you are speaking with and all reference numbers that are given to you.

With this information, you can make return calls to the same person who worked with you earlier. The reference number will allow them to access a case file on your problem, thereby speeding up any potential solutions.

Support techs may sometimes hand you off to a more experienced employee in order to provide you with an answer quickly. These veterans often have years of education in the real world, but are in high demand. It may take extra time to get a response from one of these top level support staffers.

The people manning the support desk are often trying to assist customers who have no experience doing repairs. Do not feel offended if they walk you through some very basic steps while on the phone. They have no way of knowing your level of expertise.

When a problem has been solved, be certain to write down what was done and why. This way if the problem arises again, you have the troubleshooting procedure and any calls to the support desk will be shortened considerably.

After a solution has been implemented, a call to the tech desk is a nice gesture. It will let the company know that you are up and running. If a tech was especially helpful, let a supervisor know. Techs rarely receive a pat on the back.

The next time you call a company’s support desk, try the above-mentioned suggestions. Have patience, speak clearly, speak slowly, and if you are forwarded to a recorded message, don’t run from the phone screaming something about “If I had a dollar for every time I have heard…”

Changing Lanes

With the invention of the Kegel LaneMapper, came a study about bowling lane topography like no other in the history of the game. Truth be told, when lanes were made of wood, and resurfaced in a timely manner and taken care of by craftsmen, topography was not really an issue. But with the proliferation of synthetic lanes and overlays, along with lanes getting minimal attention today, topography is much different and more influential than in past times – and the Kegel LaneMapper has been able to show it.

We now know what lanes shapes favor different type ball rolls. We know exactly why the same oil pattern can play completely different from one center to another. We know that different lane shapes can affect the durability of an oil pattern, or lane conditioner. And we know that different types of lane constructions are not created equal, nor do they change equally. It’s within this last statement this edition of the Inside Line will focus on – how synthetic panels laid on top of wood lanes can change with seasonal changes.

“All lanes look flat, but they really aren’t.”

We’ve always known that wood lanes change from summer to winter. In the days of regularly resurfaced and maintained wood lanes, we saw depressions go from the minus .010” range to maybe the minus .020” to .030” range in the winter months – a depression increase of 10 to 20 thousands of an inch. In climates where seasonal changes and humidity differences were greater, so were the changes in the lanes.

But today, because of the aforementioned lack of attention lanes receive, we are seeing changes much greater from season to season - especially in climates that have greater seasonal differences.

A big part of Kegel's original Mission Statement was “we study the game of bowling”. It was a mandate from the late John Davis. This edition of the Inside Line will focus on some of that study from bowling centers around the world, and we will show how much, and how fast, bowling lanes with synthetic overlays can change in shape.

Real World

Our first example is from a bowling center located in the northern hemisphere. Being in the north, there can be significant differences in humidity from summer to winter - it is humidity that makes wood change in shape.

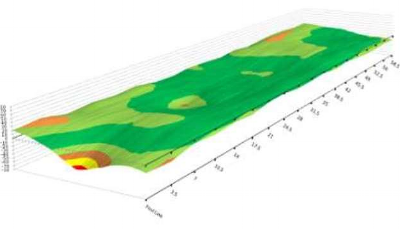

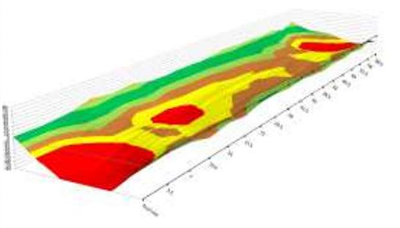

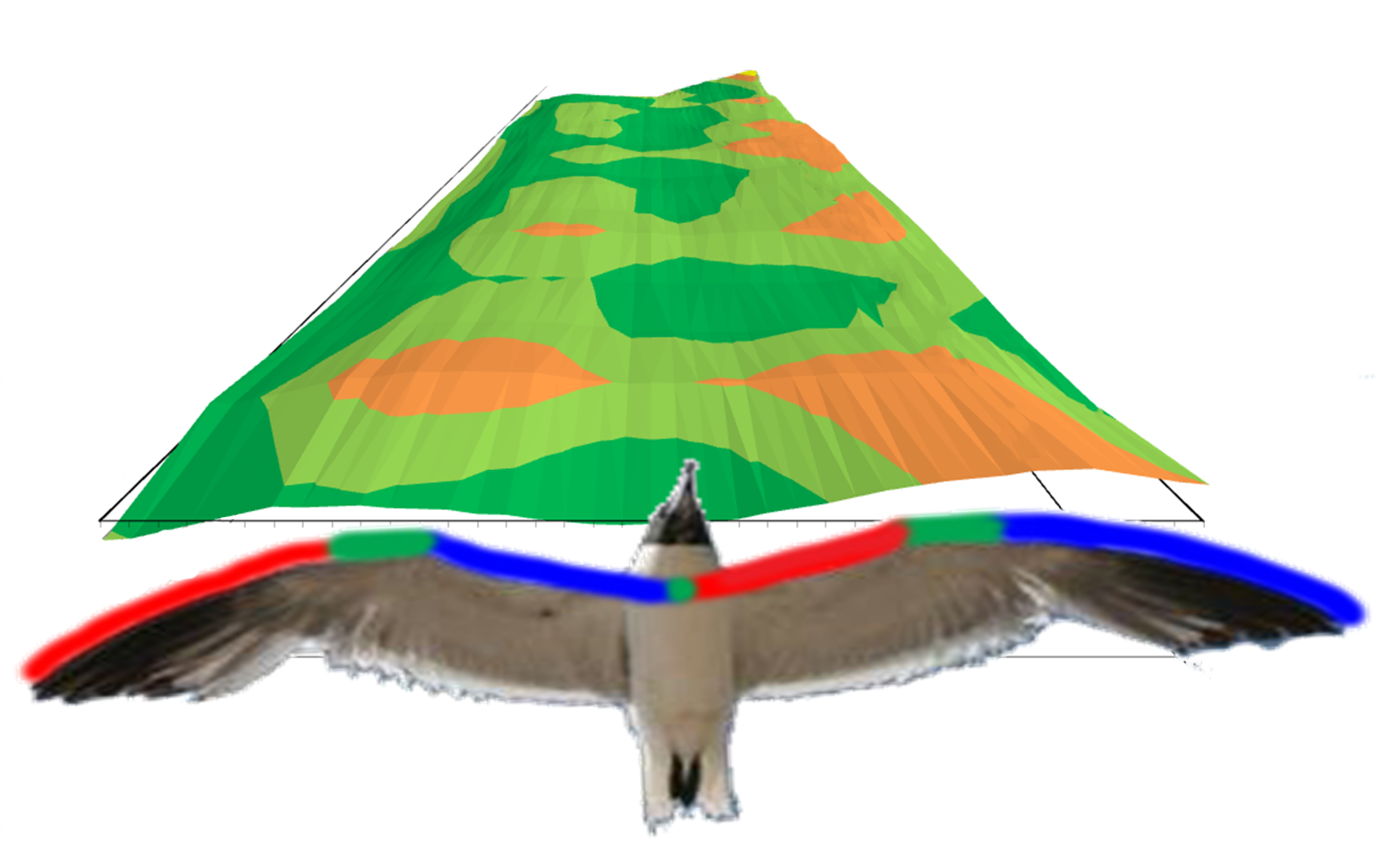

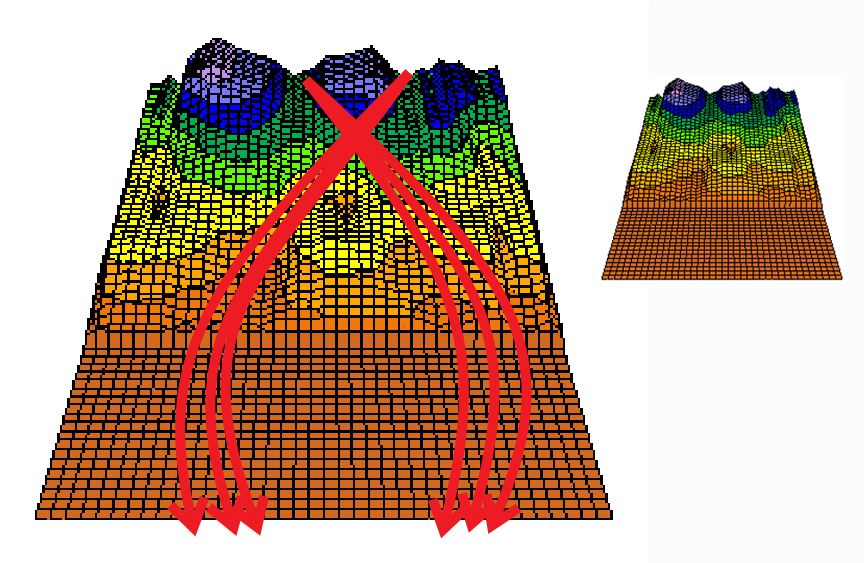

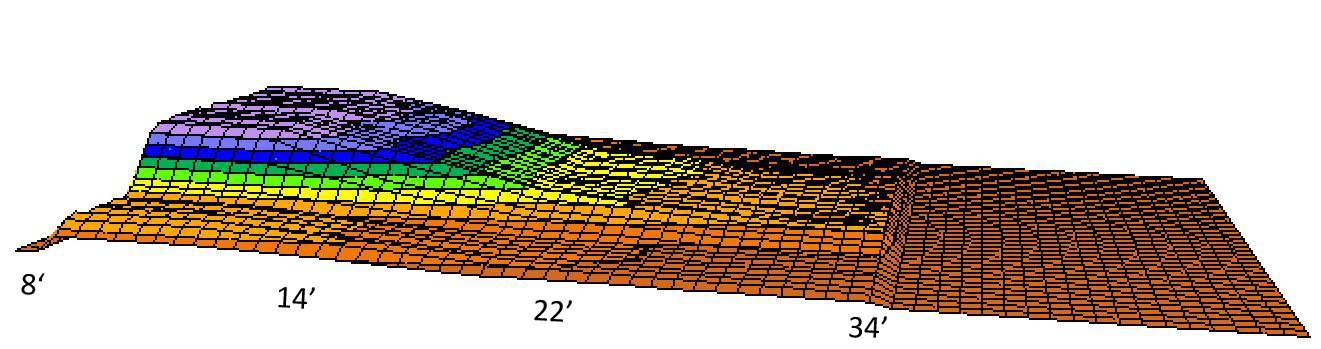

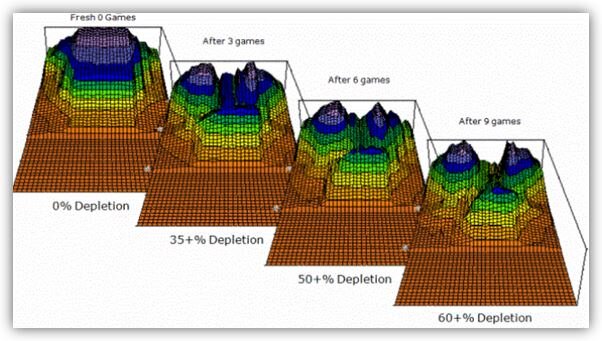

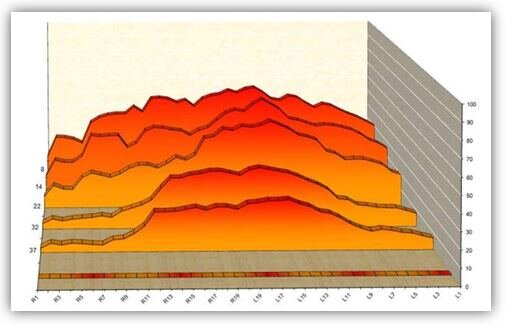

The graphic below is a lane with a synthetic panel on top of existing wood lane (overlay) in the summer time when the humidity is highest. Humidity always enters wood in the area of least resistance and with a wood lane humidity enters the wood from the bottom of the lane.

Synthetic overlay measured in August when humidity is high.

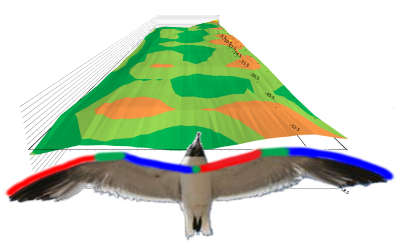

We call this a ‘bird wing’ shaped lane because the wood lane pushes the panel up between the screw rows (2L, 20C, and 2R boards) causing a hill around the 10 board. This lane shape will cause hang spots outside of second arrow, and “hook” inside of second arrow. Medium length patterns are most difficult on this lane shape.

The wood lane underneath the synthetic panel "pushes up" the panel between the screw rows causing the shape of the lane to resemble a bird wing.

What is also interesting is the lanes in this center pass the plus/minus .040” specification at every distance on the lane, in the summer time.

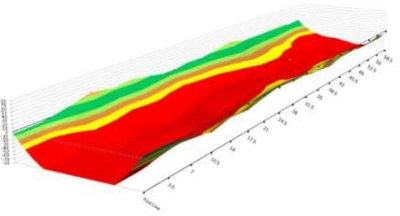

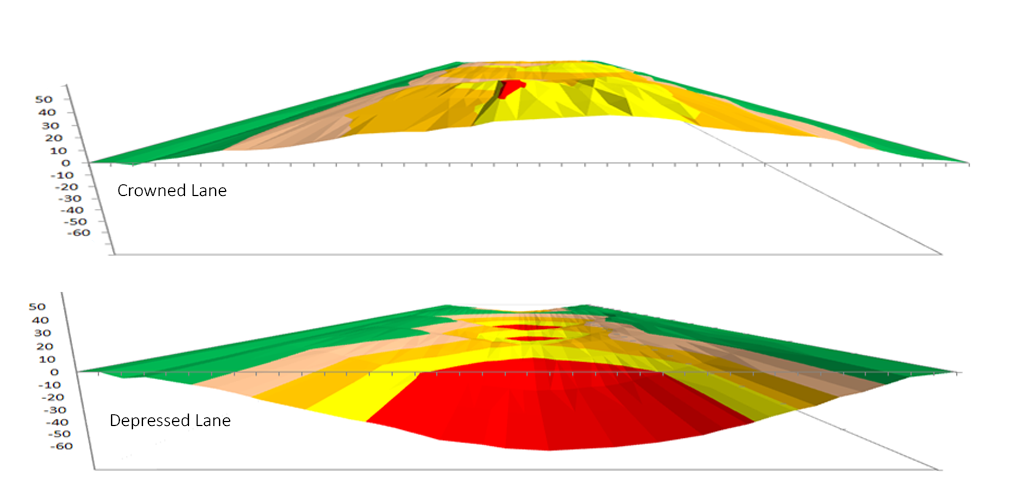

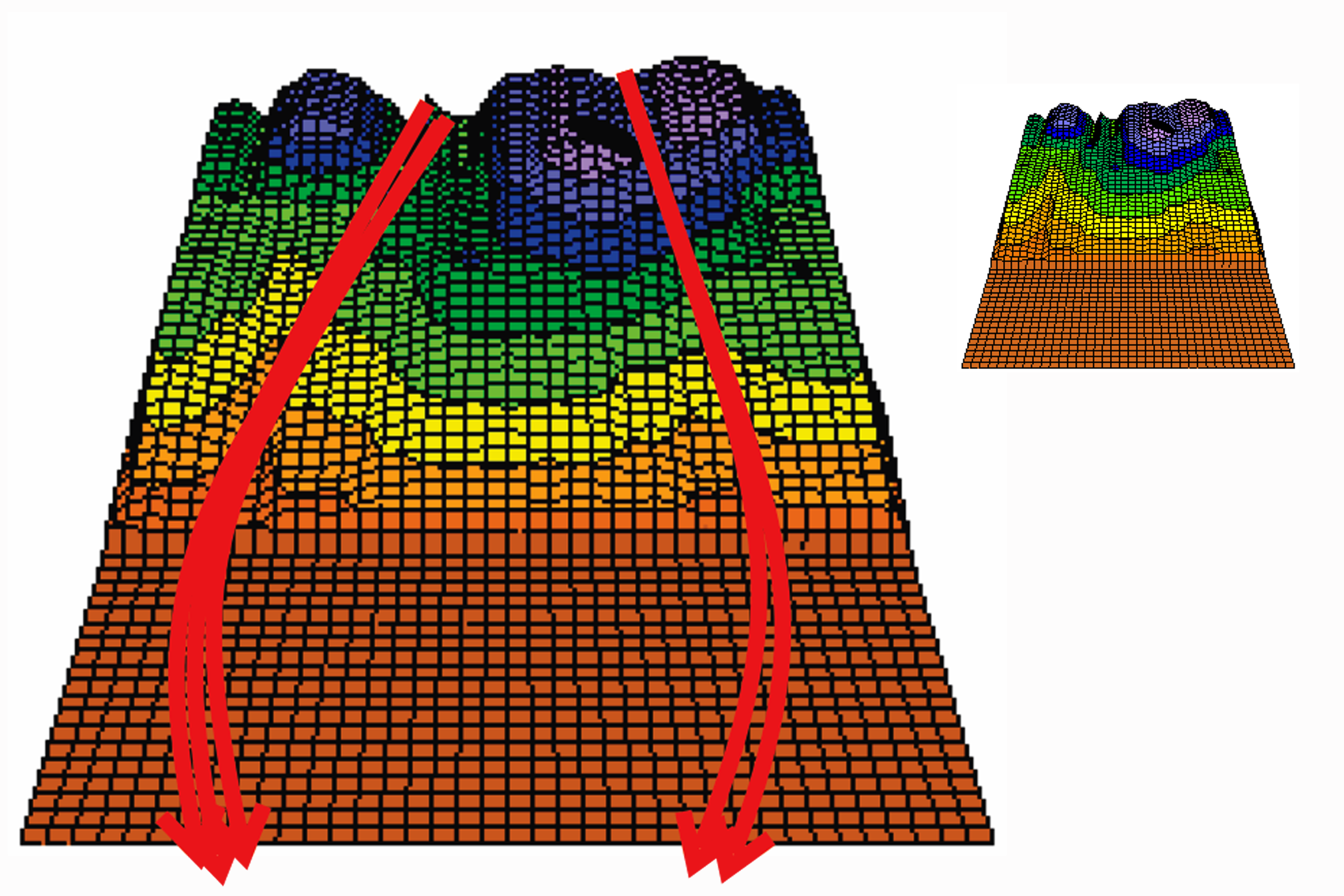

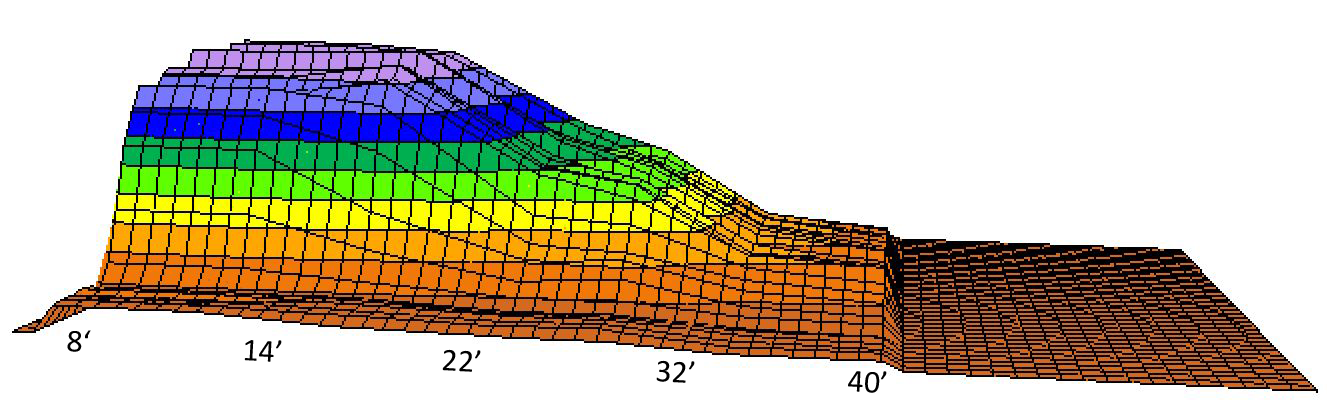

The below graphic shows what the lane looks like during the transition from summer to winter, or winter to summer. In the fall time, the humidity has decreased causing the moisture in the wood lane to also decrease - everything is contracting and the panel takes shape of what’s underneath it. In the spring time the process is reversed. Medium oil patterns begin to play easier - actually all oil patterns begin to play easier.

As the humidity begins to lower, the moisture in the wood lane begins to release, making the wood lane contract. Measurements taken in early November.

Where the lane gets the most abuse, the head area, the depressions begin to exceed the minus .040” specification. The toe screws holding the wood lane together, and the screws that hold the wood lane to the levelers below, are getting loose, or back out all together in many instances. The lane acts like an accordion.

It must be noted that when the heads are cut out and replaced with a substrate like MDF, we do not see these huge depressions. Synthetic panels on top of a substrate like MDF, HDF, or PSL, do not seem to be affected near as much during seasonal changes.

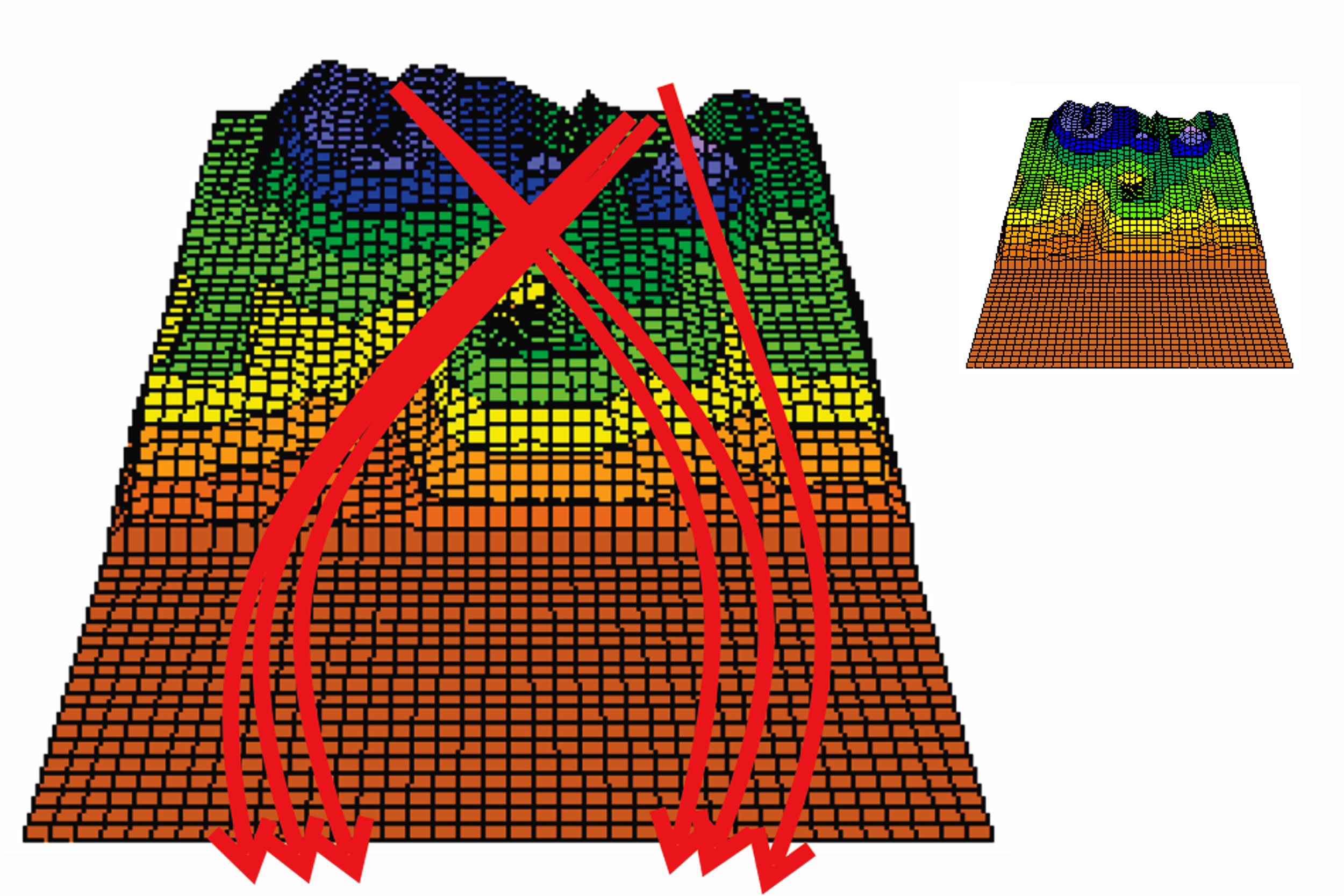

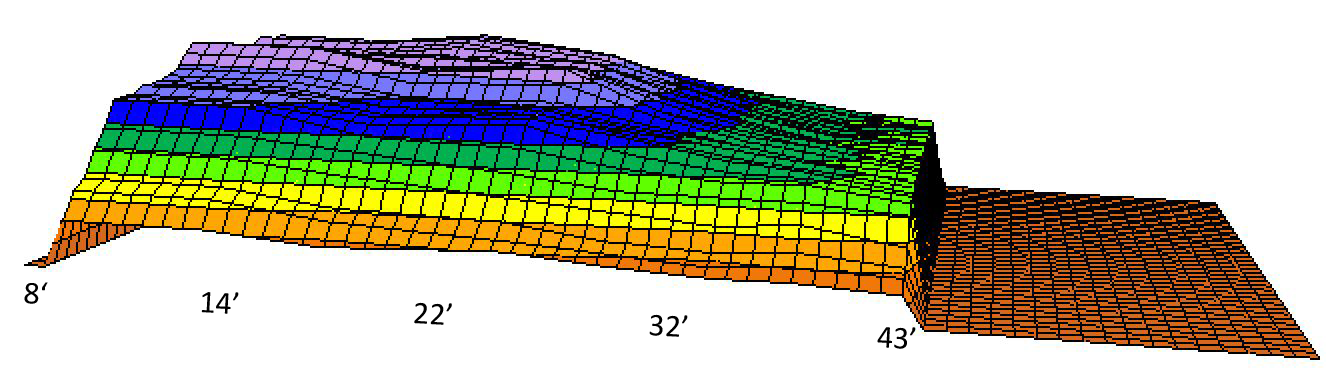

Below is what the above lane looks like in the winter time, when the humidity is lowest. In some instances, bowling centers may even turn the heat on, which lowers humidity even more. It's at this point in the year most of the moisture has come out of the wood lane and the depressions are the greatest. This is also when oil patterns tend to play the easiest; everything “ramps back” to the pocket.

When the humidity is the lowest, the depressions increase the most.

What may be thought provoking for some is, every distance on this lane has now exceeded the minus .040” specification. We have seen this in more than a few instances.

Oil patterns on a lane with depressions of this magnitude will also tend to break down quicker, when playing outside of center. This happens because there is more pressure (gravity) pushing up against the ball when outside of center so it's easier for the ball to "poke through" the oil film on the lane - the “shot” will tend to go inside quickly because of that. Think of a car rounding a curve on a banked road or race track - the banking is there to help a car navigate the turn.

This is when lofting the gutter often comes into play on competitive longer patterns - the ball will “see the lane quicker” as the pattern breaks down on the uphill slope. So players quickly move to and play the downhill side of the depression as long as they can. Physics dictates that the ball will retain energy longer on the downhill side of depression and then hook off of the uphill side easier. Once deep inside, bowlers with high rev rates, high axis rotations, and high tilts will benefit the most on this lane shape - that's physics at work also.

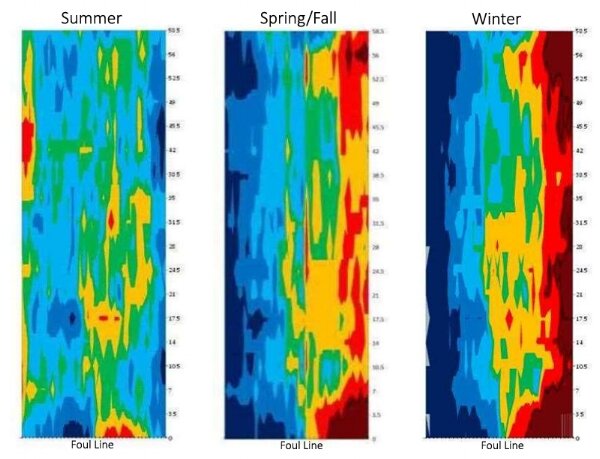

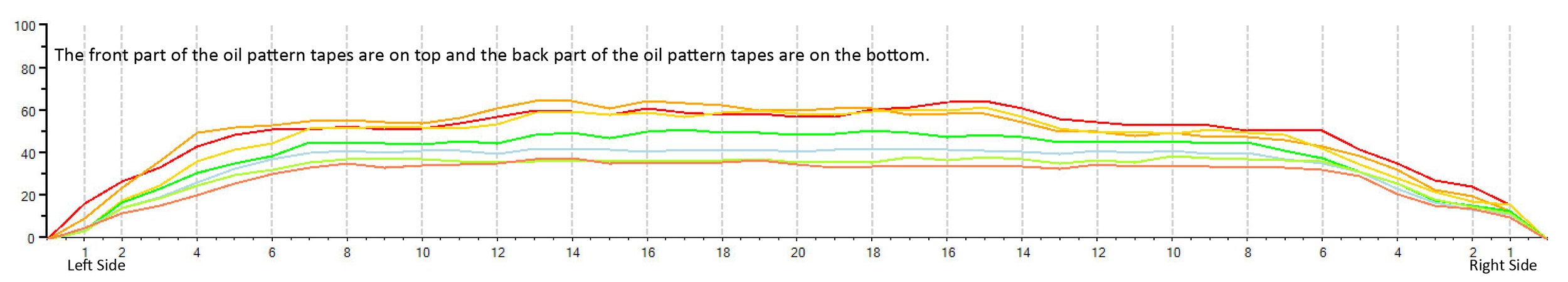

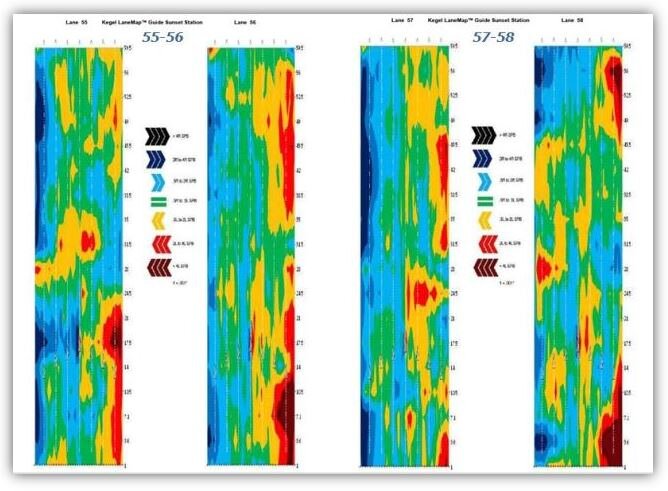

The Kegel Slope Graphs make the slope differences even more apparent:

Same lane over the coarse of seasonal changes.

The Slope Graphs are revolutionary in bowling because they are the first illustrations that show the severity of the ‘rise and falls’ on a bowling lane. Slopes to the right are in the blue color spectrum – the darker the color the more severe the slope to the right. Slopes to the left are in the orange/red spectrum - the darker the color the more severe the slope to the left. Read more about Kegel's Slope Graphs.

How fast can lanes change?

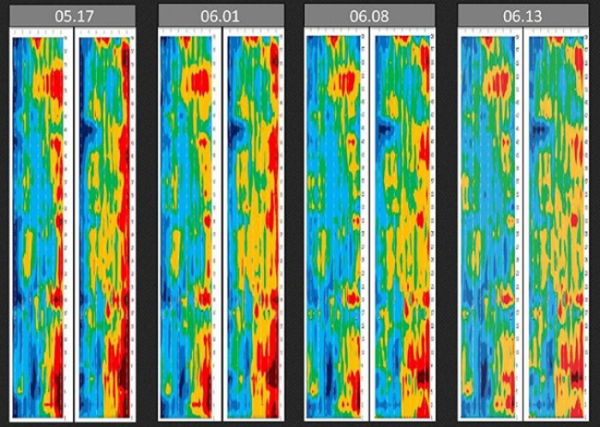

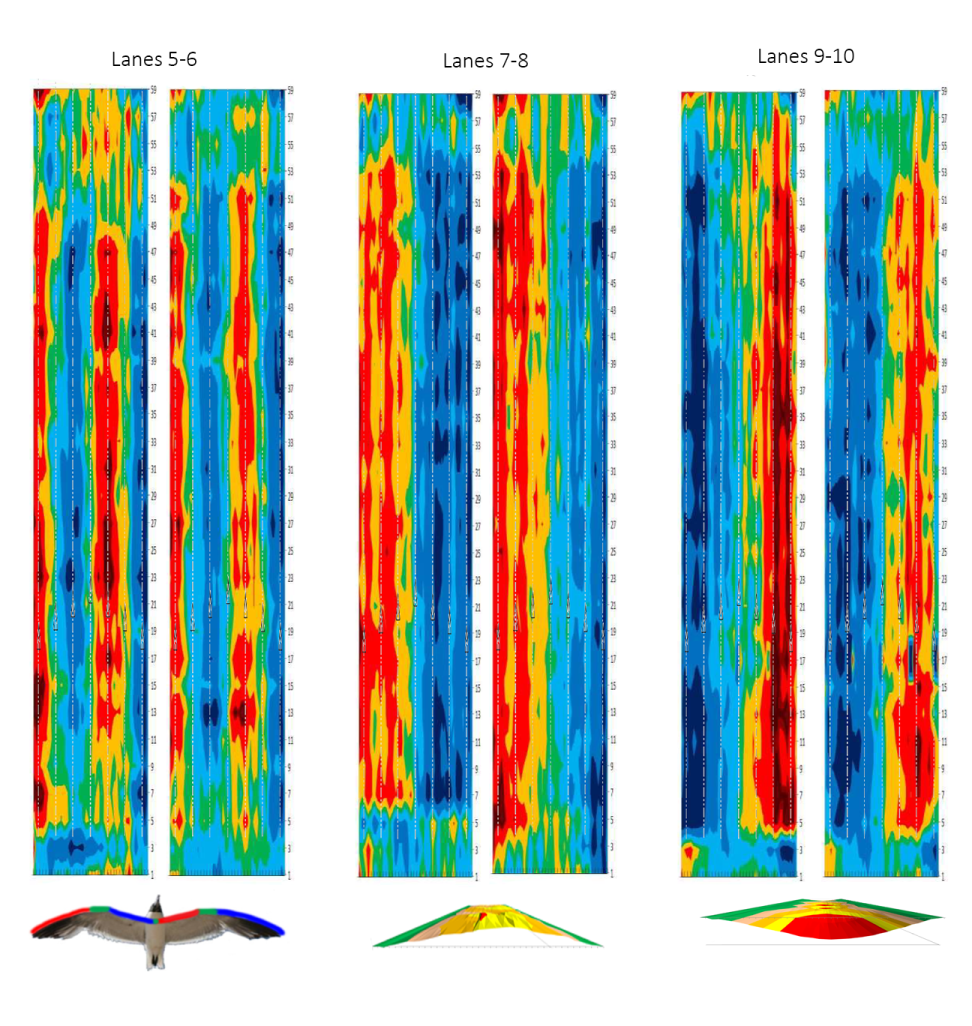

The following graphic shows how a synthetic overlay pair of lanes can change over the course of 28 days – from May 17th to June 13th. This center is also in the northern part of a country and one floor below ground level – so if anything changes are less than a center on the ground floor or above. The foul line is at the bottom of the graphic.

A pair of synthetic lanes with overlays changing during a 28 day period - from May to June. The foul line is at the bottom,

What to notice here are the slopes on the outside part of the lanes – reds on the right are slopes towards center and blues on the left are slope towards center - so the lanes here are predominantly depressed at the beginning of this time frame.

Over the course of 28 days it is clear that the depressions are decreasing. The reds become lighter in color so the movement towards center is less influential, and some areas of the lane are even turning to blue in color, which indicate slopes to the right. Hang spots are caused by these "outward slopes". What we noticed during these 28 days was "the oil pattern" became tougher as the lanes flattened out - gravity always wins on planet earth.

If we talk about the raw data, the lanes were changing (swelling up) about 6-7 thousands of an inch per week as it takes in moisture. In 28 days the depressions went from the mid-minus 30 thousands of an inch to less than 10 thousands of an inch. And the process will reverse itself come fall time as the wood releases all that moisture.

“Gravity always wins on planet earth.”

How this can help you – the proprietor, the bowler, the coach, the federation, or the tournament organizer.

With synthetic lanes it’s even more crucial to see these slopes because it’s the only way we can really understand what’s happening with ball motion – is it friction or a significant slope causing the ball to hook too much, or not enough?

Knowing the shape of the lane at different times of the year will tell you the answer, and it will also tell you how an oil pattern will play, develop, and breakdown.

For instance; when the wood underneath the synthetic swells up in the summer your pattern will play longer or it seems like carrydown comes out of nowhere – the ball has a hard time moving towards center, when the lane is sloped towards the gutter.

This lane swelling can also "make the shot" go more inside as bowlers stay away from the hang area towards the outsides.

This is especially important to any one bowling center when trying to provide lane conditions for their weekly league customer base. If your center has lanes that change as much as these examples, you may need different house patterns for different times of the year so the house playing characteristics stay more similar.

It’s also important to know if a bowling center wants to “experiment” with a different oil pattern or try a new chemical product. If you don't which way your lanes are changing, or how much, it will be difficult to know why things are playing the way they are.

It’s important for tournament organizers or federations to know so when they ask for a pattern months in advance they have a better idea of what to expect come tournament time. Testing an oil pattern in one part of the year and expecting things to play the same at another time of year will often make the question "what happened" arise.

It’s important for coaches and bowlers so they can properly prepare for an upcoming tournament, or make the proper adjustments when the bowling ball is not reacting like they think it should.

Technology can definitely make life easier when used in the proper manner – the Kegel LaneMapper is one of those advances.

When used it can definitely help a bowling center get know their lanes better and use oil patterns that compliment the predominant shape of those lanes to provide more consistent playing conditions for their customers.