Oh No! My pattern is not playing the same as last year!

By Doug Dukes - Kegel Technical Sales Specialist and Kegel Pinsetter Parts

"My pattern is the same as last year but it is not playing the same" is one of the #1 lines we hear this time of year. As one of the techs at Kegel that has the privilege to not only help all of you on the phone, but to also work on lane machines in the field, let’s take a look at some overlooked parts and adjustments to your lane machine.

CLEANING - “You can’t paint the Mona Lisa on a piece of toilet paper.”

The number one overlooked problem on a lane machine is its ability to clean. Anytime a pattern adjustment is requested because they don’t play the same, our first question is “have you done a clean only”.

On Spray Jet machines, the screen check valves (153-0220) should be taken out regularly and cleaned. Lint build up on these can wreak havoc on the jet's ability to spray properly and as the check valves get weak, your spray tips can drip. If you notice that your machine is using less cleaner, it may be a good time to take these screens out and clean them. There are also two filters that cleaner passes through before it gets to the screen check valves, one in the tank (154-0212B) and one inline filter before the pump (154-8867A or 154-8887). It is always good to replace these filters every summer.

On Sprayless Cleaning Systems, you need to replace the two filters talked about above, but also your Norprene tubing in your cleaner pump (154-0861B). This style cleaner pump operates by using a set of rollers that press cleaner through this tubing every time the motor turns on. Over time, this tubing can lose its ability to allow cleaner to be pushed through it, and your volumes can be significantly reduced. Many times I have run a cleaner volume check on a lane machine and looked at the touchscreen only to realize that I was the last one to run the test during the yearly service last year!!! You guessed it……the volume was significantly lower than what it should have been.

Once you change the tubing, run a volume check and set it to your desired output and monitor this for a few weeks as the tubing breaks in. It will vary a bit during this time and a readjustment may be required, but it will settle in quickly. This should be checked on a regular basis throughout your season as well.

The cushion roller (153-8838 standard roller and 153-8839 roller with wrap), is another frequently overlooked piece to the cleaning puzzle. The size of the cushion is the key to your cleaning. If we think about how the cushion roller works, when the cloth unwinds, the cushion roller drops onto its stop bolts. When the machine is pushed onto the lane, the cushion actually lifts up off the stop bolts, and the weight of the cushion is what helps clean the lane. Simple right? If your cushion has gotten smaller over time, now it is not making full contact with the lane surface. This means it will not clean well. Mona Lisa and toilet paper soon to follow.

If you look at your cushion roller and see the “alligator skin” look, the ends are flaring out or torn and the cloth is visually pulling into the roller, or if you can wrap your hand completely around it, it is probably time to send it to greener pastures. One trick I show during service stops is releasing the tension on the cushion roller when you finish your lanes.

On machines that have the take up roll on the top, you can stand the machine in the transport position when finished and open the duster compartment. Slide the take up roll to the side and turn it 180 degrees and lock it back in place. This will relieve the pressure on the roller and when you turn the machine on to run lanes the next day, the machine will find “home” and wind the cloth back up for you. This can extend the life of your cushion and save you from headaches mid-season.

Squeegee blades (153-8204E Blue or 153-8834 Brown) normally are not overlooked, but why leave them out. Your squeegees should be flipped every six months, and changed once a year. You don’t want to leave any cleaner behind. Always check for your 1/8 to 3/16 adjustment as well, once you change or flip your blades and adjust accordingly.

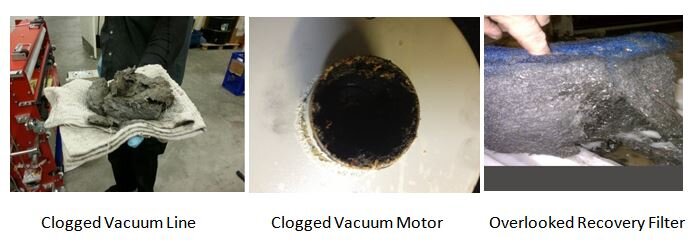

Recovery tank filters are another overlooked item in the cleaning process. Waste tank a little lighter than normal? Check your filter and change it regularly. This is the perfect time to flush out your vacuum hoses and check for small pin holes that may affect suction, along with cleaning your vacuum motor and checking the motor brushes.

Conditioning - “The best canvas deserves a worthy brush.”

A few minor adjustments in your transfer system that have been overlooked can also make you pull your hair out when you’re dialing in your pattern.

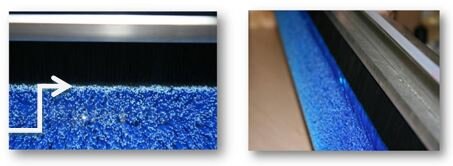

Have you checked your crush adjustments on your brush? Most people check the crush from the buffer brush to the lane and set their buffers at 1/8 to 3/16. What most people don’t check is the crush to the transfer brush or roller depending on the machine type. If it can’t pick it up off the transfer brush or roller it can’t get it to the lane!

As the brush wears, it may lose some contact with the transfer brush or roller. When getting ready for the fall season with an existing brush, or when putting in a new brush, always check this adjustment. We like to see 1/8 inch of crush to the roller or transfer brush.

On a transfer brush system, if you turn the buffer on while the brush is in the down position, you should see a thin light colored line where the transfer brush and buffer brush meet. This is from the bristles on the buffer brush being pushed together as they push against the transfer brush. Adjust accordingly.

Your pressure gauge can tell you a lot about your lane machine as well. If your pressure gauge fluctuates as you are applying loads or your pressure seems much higher than normal, you may need to clean your oil control valve. Dirt can accumulate in your valve over time and cause pressure fluctuations while applying loads. If the valve is dirty, take a good look at your filter inside your oil tank as well (154-0212). Replacing it once a year will keep you in top running order.

Your lane machine is one of the most important machines in your center. My final example I tend to give to proprietors and mechanics alike goes something like this…….

If one of your pinsetters happens to go down during a league, you may upset at most the 10 people that are bowling on that pair. But you probably have the parts to be able to fix this later that evening. If your lane machine goes down, and you have a 32 lane center that is full, you’ve now made 160 people upset, and you may NOT have the parts to fix it. You next day air the parts, but your still down the next night, and 160 turns into 320. It is extremely important that you keep your machine clean, do your daily and monthly preventative maintenance, and not take your lane machine for granted. Always keep a few parts on hand. One of every relay, two of every fuse, a fuse holder, a head drive belt, check valves, etc.

This minimal list of low-cost items can be the difference between a full house of happy bowlers, or a lynch mob and a quick backdoor exit of the center. Spend ten minutes a day, 20 minutes once a week, an hour a month and a half day every six months on your machine, and you will be able to keep it clean, and inspect the machine for wear on a regular basis. Always remember we are only a phone call away 24 hours a day 7 days a week from anywhere in the world. We are ALWAYS here to help.

Good luck and good scoring on your new season.

Changing Out Conditioners - Sanction Technology

KEGEL TECH TIP - The following is Kegel's recommended procedure for changing out lane conditioners in Kegel Sanction Technology lane machines.

Remove the conditioner tank from the lane machine.

Empty the conditioner tank into a container. Do not reuse the old conditioner.

Remove the internal filter from the conditioner tank.

Flush the conditioner tank out with your lane cleaner solution to get any leftover conditioner and debris out of tank. Repeat this step at least one more time.

After the lane cleaner solution rinse, rinse the conditioner tank out with water until there are no more soap bubbles to ensure all lane cleaner residue is out of the tank.

Note: Kegel recommends NOT USING isopropyl alcohol or any other solvent.Allow the conditioner tank to dry completely.

Clean or replace the internal conditioner filter.

Reinstall the internal filter using Teflon tape and a small amount of clear silicone around the threads.

Reinstall the conditioner tank.

Fill the conditioner tank with the new conditioner.

Put the return line to the conditioner tank into a separate container and run the oil pump so that the old conditioner left in the lines will go into the container. This will force the old conditioner out of the conditioner tubing and replace it with the new conditioner while also keeping the old conditioner out of conditioner tank.

Once all of the old conditioner is out of the conditioner tubing, reinstall the conditioner return line back onto the conditioner tank.

Perform an oil volume output test five times into the separate container. This allows all of the conditioner to be removed from the pencil tip and conditioner tubing leading to the pencil tip.

Before applying conditioner to the transfer system components, and depending on your machines oil application, clean the transfer brush, smoother pads or transfer rollers, and the buffer brush. No chemicals should be used to clean these items; just clean dry towels.

Allow the conditioner pump to run and inspect all connections for any leaks.

Check your conditioner volume output and conditioner pressure. Kegel suggests setting the conditioner pressure at 15 psi for machines with a CPM2A and C200 PLC’s. However, anywhere between the ranges of 10-20 psi is safe. Machines that have a CP1H PLC will run conditioner pressure NO lower than 15 psi and no higher than 45 psi. And remember, conditioner pressure and volume are independent of each other - pressure differences WILL NOT affect conditioner volume.

For questions or assistance, please contact Kegel Tech Support US Toll Free at (800) 280-2695 or e-mail at tech@kegel.net

How to Choose the Correct Lane Conditioner

If there is one thing we have learned over the years, it’s that every bowling center is uniquely different. Even two bowling centers located right down the road from each other, using the same lane machine type, with the same lane surface, and using the same chemicals, can have drastically different lane conditions.

By measuring the lanes of hundreds of bowling centers with the Kegel LaneMapper™, we have begun to further understand why bowling centers can vary so much. However, things such as the water used to dilute the lane cleaner, the temperature and humidity within the building, and the different bowler types or balls being used by those bowlers can influence what lane conditioner is best for any one bowling center.

The properties Kegel tests on lane conditioners in the lab are all physical properties. Because all physical properties are affected by the environment they are used in, it is often hard to find or suggest the “right” lane conditioner without a little trial and error. So how do you begin to select the right lane conditioner and set-up for your bowling center?

First and foremost, our recommendation is that if you are happy with the lane conditioner you are using, don’t change it. If you are not happy however, and were to contact us at Kegel, there are a number of factors we would talk you about to get you on the right path. The following will give you some insight into the process we use to make lane oil recommendations to bowling centers.

The first thing we would ask is what problems you are experiencing in your bowling center. Issues that might indicate you need to change your lane conditioner are:

Excessive ball calls

Excessive out of ranges

Pattern is not holding up long enough

Pattern adjustments seem “too touchy”

Scores are not what they used to be

Before you switch your conditioner however, consider these possibilities:

Oil pattern: Some of the problems listed above could simply be caused by the oil pattern you are using. If you notice any of these issues, it is a good idea to have an expert review a copy of your current oil pattern to determine if this could be the source of the problem. Check out our pattern library or contact our tech support

Cleaner type, mix ratio, or residue:

Sometimes oil related issues can solely be a cause of a certain cleaner or mix ratio. Make sure the cleaner you are using is designed to remove the lane conditioner you are using.

ALL cleaners leave some residue behind - even those that claim to be residue free. For example, toilet bowl cleaners that keep your toilet “cleaner for longer,” leave a small amount of residue behind to help repel the dirt. Though the toilet may be flushed frequently and appear clean, the residue remains. For an example of this residue at work, watch this “Drop Shape” video to illustrate the effect cleaner residues can have on a surface.

Lane machine: Maintenance and upkeep of the lane machine are just as important as the chemicals they apply. Machines that are kept clean and maintained will apply conditioner more accurately and leave behind smaller amounts of residue.

Lane topography: We have a new saying at Kegel after measuring 1000’s of bowling lanes; “you can’t fix a gravity problem with oil.” Checking today’s synthetic lanes at 3 predetermined distances does not give enough information to determine how your lane’s shape affects ball motion. The consistency and predominant characteristic of your bowling center’s lane topography can finally be seen with the invention of the Kegel LaneMapper which can measure 744 points on the lane.

The top factors affecting lane play are the environment and pattern choices. After that comes the conditioner choice, followed by a third and often overlooked factor, the cleaner selection. Make sure you have exhausted alternate possibilities before chasing the perfect lane conditioner.

Lane Surface type:

Synthetic brand, model and age – AMF HPL’s or SPL’s, Brunswick’s many surfaces, DBA IQ™, Murray Pathfinder™, Switch, etc.

Wood lanes with finish - 100% solids, EZ Coat, moisture cure, water-based, etc.

Type of lane machine: Do you have a fluid metering lane machine (Kegel Sanction Technology), a wick/pad lane machine, or spray type machine?

Lineage: how much of your business is league play with high flaring modern bowling balls vs. open play with low flaring house balls. If more than 50% of your lineage is from league play, you should opt for a conditioner that has high durability. If your business is predominantly open play, parties, and social bowling events, look for a lane conditioner that is geared to prevent ball calls and out of ranges such as Prodigy.

Environmental factors:

Temperature consistency

Humidity

Cleanliness

Altitude

For example, if you live in a dry desert area, there is typically high static in the air which can cause lane play issues. In this scenario, it is good to look for an oil to help prevent the snappier back ends caused by the high static environment.

Through our experience with bowling centers all over the world, we have being exposed to many different scenarios. Although we have come to find that certain generalizations can be made based on the type of situation, no two centers are EXACTLY the same.

Dennis Sheirs, Vice President of Kegel’s Chemical division often gets asked the question “What is the best lane conditioner out there?” His response is, “the best lane conditioner is whatever works best in your center.”

When choosing a conditioner for your center, it is important to get advice specific to your factors in order to determine the best lane conditioner for your center, and ultimately, for your customers. As always, if you would like to have company along that journey trying to find that perfect lane conditioner, Kegel Technicians are only a free phone call away - Kegel Tech Support (800) 280-2695.