Oh No! My pattern is not playing the same as last year!

By Doug Dukes - Kegel Technical Sales Specialist and Kegel Pinsetter Parts

"My pattern is the same as last year but it is not playing the same" is one of the #1 lines we hear this time of year. As one of the techs at Kegel that has the privilege to not only help all of you on the phone, but to also work on lane machines in the field, let’s take a look at some overlooked parts and adjustments to your lane machine.

CLEANING - “You can’t paint the Mona Lisa on a piece of toilet paper.”

The number one overlooked problem on a lane machine is its ability to clean. Anytime a pattern adjustment is requested because they don’t play the same, our first question is “have you done a clean only”.

On Spray Jet machines, the screen check valves (153-0220) should be taken out regularly and cleaned. Lint build up on these can wreak havoc on the jet's ability to spray properly and as the check valves get weak, your spray tips can drip. If you notice that your machine is using less cleaner, it may be a good time to take these screens out and clean them. There are also two filters that cleaner passes through before it gets to the screen check valves, one in the tank (154-0212B) and one inline filter before the pump (154-8867A or 154-8887). It is always good to replace these filters every summer.

On Sprayless Cleaning Systems, you need to replace the two filters talked about above, but also your Norprene tubing in your cleaner pump (154-0861B). This style cleaner pump operates by using a set of rollers that press cleaner through this tubing every time the motor turns on. Over time, this tubing can lose its ability to allow cleaner to be pushed through it, and your volumes can be significantly reduced. Many times I have run a cleaner volume check on a lane machine and looked at the touchscreen only to realize that I was the last one to run the test during the yearly service last year!!! You guessed it……the volume was significantly lower than what it should have been.

Once you change the tubing, run a volume check and set it to your desired output and monitor this for a few weeks as the tubing breaks in. It will vary a bit during this time and a readjustment may be required, but it will settle in quickly. This should be checked on a regular basis throughout your season as well.

The cushion roller (153-8838 standard roller and 153-8839 roller with wrap), is another frequently overlooked piece to the cleaning puzzle. The size of the cushion is the key to your cleaning. If we think about how the cushion roller works, when the cloth unwinds, the cushion roller drops onto its stop bolts. When the machine is pushed onto the lane, the cushion actually lifts up off the stop bolts, and the weight of the cushion is what helps clean the lane. Simple right? If your cushion has gotten smaller over time, now it is not making full contact with the lane surface. This means it will not clean well. Mona Lisa and toilet paper soon to follow.

If you look at your cushion roller and see the “alligator skin” look, the ends are flaring out or torn and the cloth is visually pulling into the roller, or if you can wrap your hand completely around it, it is probably time to send it to greener pastures. One trick I show during service stops is releasing the tension on the cushion roller when you finish your lanes.

On machines that have the take up roll on the top, you can stand the machine in the transport position when finished and open the duster compartment. Slide the take up roll to the side and turn it 180 degrees and lock it back in place. This will relieve the pressure on the roller and when you turn the machine on to run lanes the next day, the machine will find “home” and wind the cloth back up for you. This can extend the life of your cushion and save you from headaches mid-season.

Squeegee blades (153-8204E Blue or 153-8834 Brown) normally are not overlooked, but why leave them out. Your squeegees should be flipped every six months, and changed once a year. You don’t want to leave any cleaner behind. Always check for your 1/8 to 3/16 adjustment as well, once you change or flip your blades and adjust accordingly.

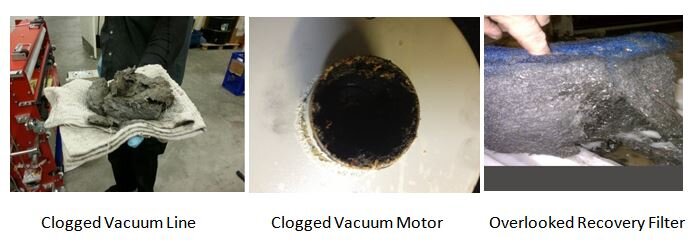

Recovery tank filters are another overlooked item in the cleaning process. Waste tank a little lighter than normal? Check your filter and change it regularly. This is the perfect time to flush out your vacuum hoses and check for small pin holes that may affect suction, along with cleaning your vacuum motor and checking the motor brushes.

Conditioning - “The best canvas deserves a worthy brush.”

A few minor adjustments in your transfer system that have been overlooked can also make you pull your hair out when you’re dialing in your pattern.

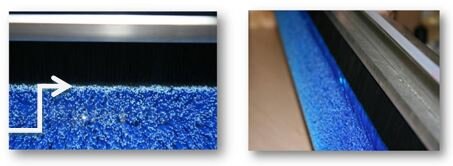

Have you checked your crush adjustments on your brush? Most people check the crush from the buffer brush to the lane and set their buffers at 1/8 to 3/16. What most people don’t check is the crush to the transfer brush or roller depending on the machine type. If it can’t pick it up off the transfer brush or roller it can’t get it to the lane!

As the brush wears, it may lose some contact with the transfer brush or roller. When getting ready for the fall season with an existing brush, or when putting in a new brush, always check this adjustment. We like to see 1/8 inch of crush to the roller or transfer brush.

On a transfer brush system, if you turn the buffer on while the brush is in the down position, you should see a thin light colored line where the transfer brush and buffer brush meet. This is from the bristles on the buffer brush being pushed together as they push against the transfer brush. Adjust accordingly.

Your pressure gauge can tell you a lot about your lane machine as well. If your pressure gauge fluctuates as you are applying loads or your pressure seems much higher than normal, you may need to clean your oil control valve. Dirt can accumulate in your valve over time and cause pressure fluctuations while applying loads. If the valve is dirty, take a good look at your filter inside your oil tank as well (154-0212). Replacing it once a year will keep you in top running order.

Your lane machine is one of the most important machines in your center. My final example I tend to give to proprietors and mechanics alike goes something like this…….

If one of your pinsetters happens to go down during a league, you may upset at most the 10 people that are bowling on that pair. But you probably have the parts to be able to fix this later that evening. If your lane machine goes down, and you have a 32 lane center that is full, you’ve now made 160 people upset, and you may NOT have the parts to fix it. You next day air the parts, but your still down the next night, and 160 turns into 320. It is extremely important that you keep your machine clean, do your daily and monthly preventative maintenance, and not take your lane machine for granted. Always keep a few parts on hand. One of every relay, two of every fuse, a fuse holder, a head drive belt, check valves, etc.

This minimal list of low-cost items can be the difference between a full house of happy bowlers, or a lynch mob and a quick backdoor exit of the center. Spend ten minutes a day, 20 minutes once a week, an hour a month and a half day every six months on your machine, and you will be able to keep it clean, and inspect the machine for wear on a regular basis. Always remember we are only a phone call away 24 hours a day 7 days a week from anywhere in the world. We are ALWAYS here to help.

Good luck and good scoring on your new season.

Changing Out Conditioners - Sanction Technology

KEGEL TECH TIP - The following is Kegel's recommended procedure for changing out lane conditioners in Kegel Sanction Technology lane machines.

Remove the conditioner tank from the lane machine.

Empty the conditioner tank into a container. Do not reuse the old conditioner.

Remove the internal filter from the conditioner tank.

Flush the conditioner tank out with your lane cleaner solution to get any leftover conditioner and debris out of tank. Repeat this step at least one more time.

After the lane cleaner solution rinse, rinse the conditioner tank out with water until there are no more soap bubbles to ensure all lane cleaner residue is out of the tank.

Note: Kegel recommends NOT USING isopropyl alcohol or any other solvent.Allow the conditioner tank to dry completely.

Clean or replace the internal conditioner filter.

Reinstall the internal filter using Teflon tape and a small amount of clear silicone around the threads.

Reinstall the conditioner tank.

Fill the conditioner tank with the new conditioner.

Put the return line to the conditioner tank into a separate container and run the oil pump so that the old conditioner left in the lines will go into the container. This will force the old conditioner out of the conditioner tubing and replace it with the new conditioner while also keeping the old conditioner out of conditioner tank.

Once all of the old conditioner is out of the conditioner tubing, reinstall the conditioner return line back onto the conditioner tank.

Perform an oil volume output test five times into the separate container. This allows all of the conditioner to be removed from the pencil tip and conditioner tubing leading to the pencil tip.

Before applying conditioner to the transfer system components, and depending on your machines oil application, clean the transfer brush, smoother pads or transfer rollers, and the buffer brush. No chemicals should be used to clean these items; just clean dry towels.

Allow the conditioner pump to run and inspect all connections for any leaks.

Check your conditioner volume output and conditioner pressure. Kegel suggests setting the conditioner pressure at 15 psi for machines with a CPM2A and C200 PLC’s. However, anywhere between the ranges of 10-20 psi is safe. Machines that have a CP1H PLC will run conditioner pressure NO lower than 15 psi and no higher than 45 psi. And remember, conditioner pressure and volume are independent of each other - pressure differences WILL NOT affect conditioner volume.

For questions or assistance, please contact Kegel Tech Support US Toll Free at (800) 280-2695 or e-mail at tech@kegel.net

How to Choose the Correct Lane Conditioner

If there is one thing we have learned over the years, it’s that every bowling center is uniquely different. Even two bowling centers located right down the road from each other, using the same lane machine type, with the same lane surface, and using the same chemicals, can have drastically different lane conditions.

By measuring the lanes of hundreds of bowling centers with the Kegel LaneMapper™, we have begun to further understand why bowling centers can vary so much. However, things such as the water used to dilute the lane cleaner, the temperature and humidity within the building, and the different bowler types or balls being used by those bowlers can influence what lane conditioner is best for any one bowling center.

The properties Kegel tests on lane conditioners in the lab are all physical properties. Because all physical properties are affected by the environment they are used in, it is often hard to find or suggest the “right” lane conditioner without a little trial and error. So how do you begin to select the right lane conditioner and set-up for your bowling center?

First and foremost, our recommendation is that if you are happy with the lane conditioner you are using, don’t change it. If you are not happy however, and were to contact us at Kegel, there are a number of factors we would talk you about to get you on the right path. The following will give you some insight into the process we use to make lane oil recommendations to bowling centers.

The first thing we would ask is what problems you are experiencing in your bowling center. Issues that might indicate you need to change your lane conditioner are:

Excessive ball calls

Excessive out of ranges

Pattern is not holding up long enough

Pattern adjustments seem “too touchy”

Scores are not what they used to be

Before you switch your conditioner however, consider these possibilities:

Oil pattern: Some of the problems listed above could simply be caused by the oil pattern you are using. If you notice any of these issues, it is a good idea to have an expert review a copy of your current oil pattern to determine if this could be the source of the problem. Check out our pattern library or contact our tech support

Cleaner type, mix ratio, or residue:

Sometimes oil related issues can solely be a cause of a certain cleaner or mix ratio. Make sure the cleaner you are using is designed to remove the lane conditioner you are using.

ALL cleaners leave some residue behind - even those that claim to be residue free. For example, toilet bowl cleaners that keep your toilet “cleaner for longer,” leave a small amount of residue behind to help repel the dirt. Though the toilet may be flushed frequently and appear clean, the residue remains. For an example of this residue at work, watch this “Drop Shape” video to illustrate the effect cleaner residues can have on a surface.

Lane machine: Maintenance and upkeep of the lane machine are just as important as the chemicals they apply. Machines that are kept clean and maintained will apply conditioner more accurately and leave behind smaller amounts of residue.

Lane topography: We have a new saying at Kegel after measuring 1000’s of bowling lanes; “you can’t fix a gravity problem with oil.” Checking today’s synthetic lanes at 3 predetermined distances does not give enough information to determine how your lane’s shape affects ball motion. The consistency and predominant characteristic of your bowling center’s lane topography can finally be seen with the invention of the Kegel LaneMapper which can measure 744 points on the lane.

The top factors affecting lane play are the environment and pattern choices. After that comes the conditioner choice, followed by a third and often overlooked factor, the cleaner selection. Make sure you have exhausted alternate possibilities before chasing the perfect lane conditioner.

Lane Surface type:

Synthetic brand, model and age – AMF HPL’s or SPL’s, Brunswick’s many surfaces, DBA IQ™, Murray Pathfinder™, Switch, etc.

Wood lanes with finish - 100% solids, EZ Coat, moisture cure, water-based, etc.

Type of lane machine: Do you have a fluid metering lane machine (Kegel Sanction Technology), a wick/pad lane machine, or spray type machine?

Lineage: how much of your business is league play with high flaring modern bowling balls vs. open play with low flaring house balls. If more than 50% of your lineage is from league play, you should opt for a conditioner that has high durability. If your business is predominantly open play, parties, and social bowling events, look for a lane conditioner that is geared to prevent ball calls and out of ranges such as Prodigy.

Environmental factors:

Temperature consistency

Humidity

Cleanliness

Altitude

For example, if you live in a dry desert area, there is typically high static in the air which can cause lane play issues. In this scenario, it is good to look for an oil to help prevent the snappier back ends caused by the high static environment.

Through our experience with bowling centers all over the world, we have being exposed to many different scenarios. Although we have come to find that certain generalizations can be made based on the type of situation, no two centers are EXACTLY the same.

Dennis Sheirs, Vice President of Kegel’s Chemical division often gets asked the question “What is the best lane conditioner out there?” His response is, “the best lane conditioner is whatever works best in your center.”

When choosing a conditioner for your center, it is important to get advice specific to your factors in order to determine the best lane conditioner for your center, and ultimately, for your customers. As always, if you would like to have company along that journey trying to find that perfect lane conditioner, Kegel Technicians are only a free phone call away - Kegel Tech Support (800) 280-2695.

Earl Anthony - Simply the Best

THE difference between the good players, the very good players, and the great players, is the mental game. But what exactly is this mysterious thing called the "mental game”?

Many of the good players and very good players possess similar physical talents to the great players, but they often fall short with their accomplishments.

Simply put, the physical game - in any sport - is how the athlete performs based on their overall talent, ability, potential, skills, and preparation. The mental game however is a totally different animal. This element of the "package" is HOW the athlete thinks.

We have all heard about how the great players are the ones who work the hardest. They are the first ones to practice, and the last ones to leave. But, there is a lot more to it than that. Desire, dedication, determination, self-control, focus, concentration, confidence, self-esteem, positive thinking, goals, visualization, knowledge, and a host of other things, must be mastered.

The following is how the late great Earl Anthony “mastered” the game of bowling.

One time Earl Anthony was being interviewed after one of his early victories by a reporter. It was in the early 1970's, and the reporter wanted to be controversial about the lefty-righty situation that had run rampant in the late 1960's. He said to Earl, "This victory establishes you as one of the best lefties on Tour. Are you happy with that assessment?" Earl looked him right in the eye and said, "I don't know anything about that, my goal is to be the best bowler."

There was another time I remember that showed exactly how the man thought. It was 1974 and he had just been named the Bowler of the Year. A press party was arranged and the award was being presented to him in his office. The wall was cleared and the photographer was going to take a picture of Earl putting up the plaque. Earl was standing toward the corner of the wall with the plaque, and someone in the crowd told him to “put the plaque in the center of the wall.” Earl replied, “No, this one is going here, and the rest of them will go across the wall.”

Earl was right, the other Five Bowler of the Year Awards eventually filled up the entire wall.

Previously, I had written a series of books called the “Final Phase”. They were instructional books to help bowlers learn about the great sport of bowling.

For one of these books I interviewed Earl and posed this question this question to him; "Earl, in my opinion, you were the greatest bowler in the world. You totally dominated the PBA Tour for more than ten years. What do you feel was the formula-for-success that you enjoyed?”

Earl’s answer was, "In my opinion, success is the result of hard work, dedication, intelligence, selfishness, and some luck. How hard you work, and how much you are willing to sacrifice to achieve your goals, will determine to a great degree your level of success.

Natural talent is a wonderful gift, and to be the very best you must have a lot of God-given talent. However, you must work hard to develop that talent.”

Earl continued on to say, “To be a winner also takes a strong mind. You must be able to focus your concentration level to a fine point, and achieve a level of confidence in your ability that is unshakable under the most extreme pressure. Most winners develop an air of arrogance, which is a by-product of the confidence that they have in their ability.

The reason I was successful, was my ability to understand and develop my mental game, as well as the endless hours of practice on my physical game. There was also a certain amount of fear-of-failure that was tempered by a small degree of courage that I used as a motivator to let me continue to fight for my goals, despite many setbacks, and a willingness to put bowling, and my desire to be the very best, above all other things in my life."

Those three interviews alone, tells you volumes about why I thought Earl was the very best. To this day I still get chills and goose bumps when I read them.

Water Walker

I think that in order to give this story as much credibility as possible, I am going to have to brag a little. I have been involved in doing the lanes with the PBA for over 800 tournaments, which included the National Tour, the Senior Tour and all seven Regions of the Regional Program. I am the only person who has done lanes for every bowler that is in the PBA Hall of Fame. In other words, I have seen them all. And, perhaps, I am really the only person who knows exactly what they bowled "on", as far as lane conditions go.

My personal All-Time Top-10, includes; Dick 'Water Walker' Ritger. You talk about TALENT. Dick was unbelievable. He was a world-class bowler, a world class guy, and later became a world-class coach. Without question he was one of the coolest, smartest, shot-makers in the history of our great sport. He could bowl on anything.

I have literally hundreds of stories of some of the tremendous feats that were performed by the greatest bowlers in the world; those that are in the PBA Hall of Fame.

This particular story took place in the early 70's. We (the Tour) were at Cranston Bowl in Cranston, Rhode Island. The weather was absolutely miserable as it had been snowing for about a week before we got there. It was 10-degrees outside when I got off the plane. Not only that, but my job as laneman was going to be a lot tougher this week because we knew in advance that the place was in bad condition because they hadn't resurfaced in a couple of years and all of the league bowlers had been complaining. And it was an old, drafty two-sided house and each side played drastically different from each other - as well as each pair playing differently from each other. I knew that I was going to hear about that.

After the first day of qualifying, Ritger was in the lead, which wasn't unusual for this 20-time champion (at the time). Almost every bowler was upset with the lanes and I had to hear about it.

That night at 2:00am I went in to do the lanes and it was now 19-below zero. There was so much snow in the motel parking lot, that and I couldn't find my car and had to walk about a mile to get to the bowl. About 15-minutes after getting there, part of the roof on the high-side (the real tough side) caved-in from the weight of the snow. It was a disaster. The janitor called the head mechanic who in turn called the Manager. He called everybody he knew to get in there to help clean up the mess. I called Harry Golden (the Tournament Director) to let him know what had happened. I cleaned and oiled the low-side then went over to take a look at what was going on over on the disaster side. There were about 20 people cleaning the water, snow, ceiling tiles and other debris off of the lanes and approaches. You could see the sky through the hole in the ceiling. I remember thinking: "I'm sure that the guys will blame me for this, too."

There were buckets on the lanes that were still catching water from the drippy roof. It was now 6:00am and the Pro's were scheduled to bowl at 9:00am. At that point I thought that there was no way. I started cleaning and oiling the part of that side that wasn't under water. When I got to the part of the house that had caved in, a "Miracle" happened. It had stopped raining and the dripping over the lanes had stopped. I cleaned and oiled the rest of the lanes. There were still some drips coming down over the lanes, but "Miracle number 2" was that the drips were only over the gutter gaps and the buckets that were placed there were catching all of the drops. It was about 8:45am now, and I took the lane machine to the back. The mechanic and all his helpers were back there huddled next to a little heater he had, and they were all trying to dry out.

When I came out of the backend, I saw about 20-bowlers standing in the settee on 31 and 32. I went over there to see what was going on. The only drips that were still coming down were over the approach on that pair and because of the full field, they had to use that pair in the tournament. Harry made the decision to leave the three buckets where they were on the approach. It was either that, or put 5 on a pair, and none of the bowlers wanted that. The buckets were to stay in place for BOTH squads.

I stayed around to watch the 1st squad bowl. After they bowled their 6-games that morning, the high game on the pair was 149. It was impossible for the players to walk around the buckets that were there to execute any type of normal shot.

Now the next squad came in to bowl. Ritger was scheduled to bowl his 2nd game on 31 and 32. It would be interesting to see what he could do there and not lose too much of the lead that he had enjoyed. When he got there for game 2 of this second day, there was a huge crowd in the bleachers, and standing behind the bleachers, as well.

I watched him (with no practice balls) alter his approach by snaking his footwork around the three buckets in a serpentine manner. I couldn't believe my eyes. He shot 279 like it was nothing. It was ridiculous.

One World - One Game

It has been almost ten years since John Davis (Founder of the Kegel Company), called together a group of experienced lane men in an attempt to further research the on-going lane conditioning problems with our Sport. It had become apparent that too many tournaments were deemed unfair by the participants and tournament organizers. Bowling ball technology had rapidly advanced and it was getting next to impossible for the lane man to do the job without some sort of social controversy. After that five day meeting in Sebring, Florida, Davis promised to undertake the huge task of taking care of lanes at every major tournament in the world and then posting those results on The Foundation website for the whole world to see. Davis and The Foundation came up with their initial slogan which was: “One World – One Game.”

The Foundation also coined two other phrases:

1. "You don't need to be a lane man to know that there are problems, you just need to be a lane man to know how bad the problems are."

2. "If not us, who? If not now, when?"

Early on, a series of scratch tournaments were developed, called: The Foundation Games. These events were held in this country (and abroad) with some promising results. They were unique by featuring ‘multiple conditions’ in an attempt to further challenge the participants by having more than one lane condition to compete on. Challenging oil patterns were used (both long and short) that required the athletes to compete on different lengths of oil during competition.

In 2000, Dr. P.S. Nathan, then President of the World Tenpin Bowling Association (WTBA), held a World Bowling Seminar in Malaysia and Davis was invited to attend along with many other bowling leaders from around the world. At that week-long educational meeting, it was unanimously decided that in order to find out who the best players were at any given event, the athletes needed to be challenged with these ‘multiple condition’ type tournaments.

The WTBA then formed a Technical Committee (TC) to continue researching the problems on a world wide basis. Since then, different tournament formats have been tested along with bowling ball restrictions (amount of balls used in the events) which were instituted. It is quite clear today, that some of the underdeveloped countries are at a disadvantage regarding bowling equipment.

For many years now, numerous thoughts, opinions and feelings about lane conditioning have been constantly expressed on most every bowling websites discussion groups. Depending on the average person’s position (agenda), most blame the problems with our game on various aspects of the game, including; pins, oil patterns, balls, kick-backs, flat gutters and an assortment of other things. Most have never done lanes and have no idea what that particular job entails.

Today, even with the use of different formats and multiple conditions, problems still exist in our great sport. The WTBA Technical Committee feels that it is time to try a different approach.

"One World - One Game - One Ball"

In 2003, Davis was named as Chairman of the WTBA TC, and Kegel was still taking care of all the tournaments for the WTBA and developing countless oil patterns. It became obvious that the lane man still could not do his job without some social unrest. Something else was needed.

The WTBA TC decided to research and test a type of bowling ball that would not mutate the oil patterns as much as today’s High Tech balls do. Davis was put in charge of doing the research for this project. Days, weeks and months went into this very technical testing, using CATS data.

A ‘prototype’ bowling ball was developed which showed encouraging results. During the week of April 17-22, a Bowling Writers meeting was scheduled in Orlando, Florida (which is only about 80 miles from Kegel’s Training Center), that was combined with the USBC Annual Meeting.

The WTBA TC also scheduled a meeting at this time and this was a chance to announce this new theory. A small scratch tournament would be held and the results would be shown to the world. Many top players from Florida would participate along with some other top amateurs and former PBA Tour champions. It was an eight game event that was bowled across eight lanes. The amount of oil that was used was 7.140 mL, which is an amount that was used in the early 1970’s.

Those results (total pin fall) were:

1. Bob Learn, Jr. (1880)

2. Vernon Peterson (1770)

3. Matt Gilman (1715)

4. Bob Handley (1675)

5. Mike Purdy (1671)

6. Larry Barwick (1670)

7. Rob Comito (1666)

8. Steve Johnson (1660)

9. Neil Stremmel (1655)

10. Storm DeVincent (1627)

10. (T) Sami Luoto (1627)

12. Chris Chartrand (1612)

13. Dennis Davis (1598)

14. Craig Auerbach (1596)

15. Saul Insignares (1573)

16. Tony Lavance (1572)

17. Ron Dixon (1523)

18. Jose Rodriquez (1514)

19. John Forst (1513)

20. Dennis Psaropoulos (1512)

21.Tony Crews (1477)

22. Bill Blackwell (1454)

23. Pekka Korpi (1383)

24. Josh Moore (1354)

Each player paid a $100.00 entry fee to enter the tournament, and that included a bowling ball. Each player had a choice of 15 or 16 pounds to use. Except for that weight difference, all of the balls were made as similarly as humanly possible. Davis donated an additional $2600.00 for a total Prize Fund of: $5000.00. Learn earned $2000.00 for the win along with a very nice banner that was signed by all of the participants and those on the WTBA TC. In all, 12 players cashed.

When asked if he wanted the banner, Learn said, “Certainly. It will go in my trophy room with all of my other cherished awards.” He added, “This was great. ALL tournaments should be like this one because I really think that it was the fairest tournament that I have ever bowled in.”

After the event, all the players were asked to fill out a detailed questionnaire that had a multitude of pertinent questions regarding the tournament. Those queries are currently being analyzed.

All in all, it was deemed a tremendous success by the Players and Officials. All results of the CATS data (from every shot, from every player) are also being analyzed. When completed, a detailed report will be sent to WTBA President Heikke Sarso for review.

STAY TUNED!

The Beginning

The year was: 1956.

The place was: Hillsdale High School in San Mateo California

My first recollection of Billy Hardwick was that of disbelief. What a sight it was. He was a sophomore, a year behind me in school. He was all of 5’3” and weighed-in at exactly 99-pounds.

He came out and (tried out) for the Varsity football team. The Head Coach, Frank Collins, looked at him and said that he was too small to play, but since we were a new school and needed players, he told Billy that he could hold the blocking-bags during practice. He also told him that because of his size (or lack of it) that he wouldn’t be able to issue him a team uniform.

But, Billy had guts and said that he still wanted to play and practice with the team. It was a cold and rainy day in September. There he was in his ragged, old sweat-shirt, sweat-pants and wearing his tennis shoes. The shoes were those old “high-top” canvas style and the laces were tied around the tops about 4-times. His skinny, little ankles were way too small to fill-up the tops of the shoes and it looked like he was walking around with two small “sacks-of-potatoes” hanging off of the bottoms of his legs.

The practice field was very wet and muddy that day, and the first chance I had to block him and the big blocking-bag that he was trying to hold-up, I put a little bit of an “extra” effort into it. The poor little kid had no chance. He went slipping and sprawling and sliding before eventually ending up on his back in the middle of a huge mud puddle. On his way down, all you could see were arms and legs going in every direction as he tried in vain to maintain his balance. It was an absolute riot. Even all of the Coaches were laughing.

I intentionally humiliated him once again when I reached down to help him up and purposely stepped on his foot with my football cleats. He let out a scream and rolled over (face first) in the mud. Now, he was covered from head-to-toe in the sloppy quagmire. It was hilarious. Everybody there was howling. Everybody that is, except for Billy. Looking back though, I was probably a big “bully” for doing that to him. Even though he never said it, I am sure that he hated me for doing that to him.

Basically that was the end of his football career. He did go on to play on the basketball, baseball and cross-country teams. Despite his slight stature, he was a fierce competitor. As the years went by, he would eventually prove “that” to everybody. His burning desire that he possessed soon became evident when a new bowling center opened in our town and he was finally able to find (and master), his sport.

During that year we became the best of friends, and that friendship has been a close one for 6-decades. I owe him a lot from what he has taught me and the countless doors that he has helped me to open. We have (personally) endured a lot together and I have countless stories about him. I will be telling some of them here……at least the ones that are suitable for print!!!

History tells us that he did go on the Tour, twice becoming Bowler of the Year. He was voted in the top 20-players of all-time and inducted into both the ABC and PBA Halls of Fame.

Today, Billy is alive and well and owns a very successful bowling center in Memphis, Tennessee. I still see him now and then and occasionally talk with him on the phone. If you see him, tell him that I said hello.

By the way, he did pay me back. Yeah, he was the rotten egg that got me into bowling!