Silicone is Not a Four Letter Word

We’ll say it right up front - silicone in lane conditioners is a good thing. That’s right, it’s a good thing. In modern chemistry there are no other additives that perform, and are as safe, as silicone.

The idea of using silicon in place of carbon did not come to be until the early 1900’s, and the first patent ever issued for a silicon containing chemical was not issued until the 1940’s. This is when the term 'silane' was developed, later to be known as silicone.

In the early years of development, silicone products were developed and used everywhere with great success. But then some problems arose with silicone, and it came from wood polishes. It was noticed that these new products repelled water, and when people started to re-coat the furniture and floors that were polished with this new stuff, they could not get the finish to wet - the finish would fish-eye everywhere. Eventually they figured out the silicone was not cleaned off the outer layer of coating and when they sanded the furniture, they literally sanded the silicone into the wood.

A similar problem occurred in the bowling industry in the late 1970’s with a lane conditioner called 42/40. That lane conditioner was silicone oil and it created a bunch of problems with re-coating a wood lane, and this is when silicone was "deemed bad" by the bowling industry.

However, it was found that you could actually re-coat wood lanes in bowling centers that used 42/40 with success and without problems, it just required more work. A fish-eye remover was required to get the finish to wet the lane surface again, and ironically, almost all fish-eye removers contain a type of silicone.

So to say something has silicone in it, and therefore it is bad, is a very generic statement. But that’s what has happened in the bowling industry.

Currently there are thousands of chemicals that contain the Si (silicon), and they can be found in everything from cleaners to adhesives. In cleaners, there are silicone based surfactants and silicon based builders, with some of these even being used in the bowling industry today.

The reason for using silicone chemistry in products is simple; performance. Most silicone additives are used in very small amounts, typically less than 0.5%. With carbon based additives on the other hand, it takes 1-3% of those less safe amounts to achieve a similar performance effect.

Kegel uses 0.1% or less of silicone chemistry in its lane conditioners to increase performance, while keeping a focus on safety. The advantage with using this technology is achieving the desired properties with maximum safety for everything the conditioner comes in contact with, and those products are tested extensively to ensure just that.

Nevertheless there are still some that like to promote their products as silicone free, as if it’s a good thing. But, the alternative chemistry available for use today is much less safe in terms of health.

Don't fall for a sales or marketing pitch on a fear of something that happened a long time ago in a much lower tech era - chemistry has come a long way over the years. If you read the material list on the back of a product in your house you will find silicone in most of them. Silicone performance and safety make it great choice for use in everyday products, and also in lane conditioner. Bottom line, silicone is a good thing.

Read more about Silicone from Dow Corning

Read more about Silicone from the American Chemistry Council

10 Things That Everyone Should Know About Lane Conditioners

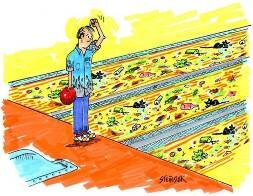

There has been a lot of scuttlebutt written about the bowling ball evolution. The dramatic changes in cover-stocks, weight blocks, drilling techniques, ball reaction, you name it. What about lane conditioners? Bowlers are quick to take credit for when they bowl well and in some cases rightfully so, but we all know that when they have an off night it's seldom the bowlers fault…..it's the LANE CONDITIONS! Believe me, I'm a long-time bowler myself and I am just as guilty as the next guy. So why isn't there more information explaining the TRUTH about lane conditioners?

Today's products have numerous additives, varying viscosities, different levels of surface tension, and many other components to give oil companies reasons to proclaim that their product "Holds Up Longer", and "Doesn't Carry Down." This is all fine and dandy, but what does it all mean. The following is a list of ten very important things that everyone should know about lane conditioners. We will talk about what everything really is and why it is important when choosing or applying a particular lane conditioner. Hopefully this will help clear up some of the confusion that surrounds this mysterious invisible substance.

1. Solvent Based / 100% Solids / High Performance

Solvent Based conditioners were developed in the 40's and used primarily during the rubber and plastic bowling ball era. Some are still being manufactured and used in bowling centers today. The basic idea was that solvents would be added to the mineral oil base which would help break down dirt and aid in the cleaning process. This was very important at that time because most centers were only cleaning anywhere from once a week, once a month, or never, but who can blame them really when they were doing it by hand.

100% Solid conditioners were simply a progression to having no solvents in the formula. This was brought upon by the urethane bowling ball era and technically can be used to define most lane conditioners in production today. From the mid 80's to the mid 90's, products contained anywhere from 4-8 components with mineral oil being the main one usually accounting for about 98% of most formulas.

High Performance conditioners are becoming more popular and necessary in centers now to help combat the aggressive bowling balls. The ultimate goal of these products is to minimize change in ball reaction and maximize application consistency. The percentage of mineral oil can be as low as 75% in some formulas with the total number of components reaching the 14-16 range. These new components or additives (which we will explain later) are items such as friction modifiers and lubricity agents.

One important thing to note here is that conditioners have evolved as well. Most of our bowlers are not throwing the same bowling balls they did when older conditioners were made so it is imperative that we "Maintain Par" and move towards using products that are designed specifically for today's environment.

2. Viscosity

Definition - The measure of the internal friction of a fluid. This friction becomes apparent when a layer of a fluid is made to move in relation to another. The greater the friction, the greater amount of force required to cause this movement, which is called "shear." Highly viscous fluids therefore, require more force to move than less viscous materials. Also, the unit of measurement for viscosity is the centipoise (cps).

Importance – There are some very important things to know about viscosity. With older conditioner technology, higher viscosity generally equated to a “hookier” conditioner while lower viscosity generally equated to a “slicker” conditioner. Fancy lubricity additives and friction modifiers (which we’ll discuss later) have made this old generality untrue. Viscosity isn’t nearly as important as it once was. It still has value though; higher viscosity conditioners won’t work well; if at all; in a wick machine. And, higher viscosity conditioners may require some adjustments to pressure regulating tubing in some lane machines.

Viscosity & Lane conditioners

Second Most Important component of a lane conditioner

Lower viscosity conditioners flow better and more consistently through wicks

New additives lower the importance of viscosity

3. Surface Tension

Definition - Surface tension is a study of how well a liquid wets a solid. This is a pretty technical section so I'll do my best to keep it simple.

Most manufacturers check surface tension in relation to air. That is the number that is given on the certificate of analysis.

It can also be measured by internal liquid/solid interaction. What that means to you and me is how well a conditioner recovers, or "Self Healing", when a ball rolls through it. The goal being that the conditioner will flow back together once the ball travels through the conditioner.

Surface Tension is also directly related to surface energy. All lane surfaces have a surface energy that can be different from surface to surface and by the conditioners and cleaners applied to it. Let me give you an example:

If you apply wax to the surface of your car the water will bead up and not "wet" your hood. The energy of the hood was changed and you will protect the paint because the water will not penetrate.

Our goal with lane conditioner is the exact opposite. We don't want the conditioner to bead up, we want it to lye down and form a bond to the surface. This helps create durability and also helps enhance the self-healing characteristics.

Importance - Studies are being done now on this topic that will help us gain some valuable ground on today's bowling balls. There are also complimentary studies testing the relationship with conditioners and bowling ball cover-stocks. The perfect lane conditioner is one that likes the lane and not the ball giving us ultimate durability. I hear the Trojan horse is on its way.

4. Temperature

Effects on Lane Conditioner - I can't say enough of how important temperature is to lane conditioners. Many people have their theories about how lane conditions change when the weather changes so we decided to get some hard facts.

In early 1997, we conducted several tests to see how much conditioners changed when the temperature was raised or lowered. What we found was eye-opening. The viscosity of some conditioners changed 2 cps (centipoises) for every 1ºF of temperature change. That means if you start with a 20cps (viscosity) conditioner and the temperature drops from 80 ºF to 70ºF, the viscosity of that conditioner would be 40cps. This is not true for all lane conditioners. Some only change 1cp for every 2º F of temperature change. That is only 25% the change as some of the others, BUT regardless of how much they change it's important to know that all of them do.

Temperature affects the molecules of lane conditioners by causing them to slow down when cold or speed up when hot. Think of water turning to ice and water boiling.

Temperature will affect the viscosity, which in turn also changes the flow rate through wicks.

When the viscosity of the conditioner is changed the ball reaction will also be different as a result.

The capillaries in most wicks will shrink up when it gets colder restricting flow.

Tips:

Keep the lane conditioner in a temperature controlled environment. (Office, Front Desk, or wherever the temperature is constant)

Keep the lane machine in a temperature controlled environment so the machine functions properly as well. We understand that this may not be possible in all situations so you can look for other solutions like an electric blanket or a space heater to keep the machine warm.

5. Order of Addition

Definition - The order of which ingredients are combined in a formula to create a desired result.

This is just a little inside information to share about the sensitivity of lane conditioners. If I was given the ingredients to one of today's conditioners, not only what was in the formula, but also how much of each, I still would have no shot at making the product.

The order and timing in which the components are added together is equally as important as the components themselves. When mixing a cocktail the order is always: ice, liquor, and then mixer. If we poured the liquor in a drink last what would happen? The liquor would float on the mixer. This is simply because the density of the mixer is usually greater than the liquor.

The main thing to understand is that there is more actual "chemistry", not just "mixing" taking place with today's products.

Tip: Leave the mixing to the chemists. Some centers are mixing different conditioners with some success, BUT we do not advise doing so based on the technical make-up of conditioners today.

6. Additives

Definition - The components added to a lane conditioner formula to enhance performance and to create desirable changes to the physical properties.

There are many things that we expect from our chosen lane conditioner. We expect it to be slick, but not too slick because of ball calls. We expect durability, but some breakdown for the lanes to open up. We also expect the infamous, "NO CARRY DOWN." Trust me, if you see a company's ad saying their oil does not carry down, don't believe it. If it's liquid, it moves. ALL OILS CARRY DOWN.

However, different additives are used to minimize the carry down and create an illusion so the ball doesn't see what the eyes do. That means some conditioners use a tacky mineral oil so ball reaction doesn't change when oil is carried down.

Some of the additives used are:

Friction Modifiers - Designed to reduce friction

Viscosity Modifiers - Designed to change the viscosity

Flow Agents - Used to enhance the flow properties of a conditioner through wicks.

Lubricity Agents - A spin-off of the friction modifier to enhance the lubricity of a conditioner

Surfactants - Short for "Surface Active Agents." These additives change how a conditioner "wets" or spreads out on the lane. They also control how well a lane conditioner flows back together when a ball rolls through.

7. Quality Assurance

Definition - Quality procedures that aim to PREVENT non-conformities.

I think every mechanic will raise their hand when asked the question, "Have you ever had a bad jug of Oil?" Unfortunately, this job continues to get more difficult by the day.

All lane conditioners are made with raw materials and various additives. Mineral Oil is a true Raw Material whereas most additives are made by chemical manufacturers by other raw materials.

Here's the process when lane conditioner is different:

The bowler complains to the mechanic or manager.

The mechanic or manager complains to the distributor.

The distributor complains to the manufacturer.

The manufacturer complains to the raw material manufacturer.

The raw material manufacturer complains to the ground.

Who's to Blame? Manufacturers today are forced to test all raw materials before they are used in production. Adjustments are commonly made to the overall formula to compensate for any changes in the materials.

Think about manufacturing lane conditioner like making your favorite recipe. Let's say that favorite dish is Lasagna. One of the main ingredients in lasagna is meat. If the meat you purchased last time had more salt in it than the meat you purchased for this batch of Lasagna you would be forced to add more salt so the dish tastes the same.

I know this example may seem like a stretch, and making lane conditioner is much harder than making lasagna, but in many ways they are the same. Chemists and Cooks are constantly trying different ingredients in search for the magic recipe. In relation to Quality Assurance, they both have to test and make sure that all the ingredients are the same before using and make adjustments to compensate for inconsistencies.

8. Quality Control

Definition - Quality procedures that aim to "DETECT" non-conformities.

Quality Control is an equally important procedure as Quality Assurance. Its role is to detect any non-conformities or changes in the product after it has been manufactured. These include a series of tests to check the viscosity, weight, surface tension, UV additive, and flow rate.

Some manufactures also use a variety of on-lane tests that ensure ball reaction and breakdown is the same as well. This is basically a big giant "DOUBLE CHECKING" of the finished product before it is shipped.

Continuing on the food theme this can be viewed as the taste test before a meal is served. Together QA and QC perform a specific and very important role. They guarantee that a finished product is exactly what it's supposed to be.

Tip: Find out what procedures your manufacturer uses for QA and QC. Make sure that you feel confident that your chosen brand is doing everything it takes to ensure product consistency.

9. Shelf Life

Definition - The amount of time determined by a manufacturer that their product must be used by in order to guarantee satisfaction and consistency.

We've already explained that mineral oil is the main component in lane conditioners. Mineral oil alone has a very long shelf life. Because the newer conditioners use less mineral oil to make room for other components the shelf life is not as long, ranging from 12 to 18 months.

Think about the shelf life of common food items such as milk and bread. When the ingredients are exposed to air they will deteriorate and lose their originality at a faster rate.

When raw materials are used for lane conditioners, they too are taken out of their natural state and exposed to air. This simple fact has forced the manufactures to advertise a shelf life in order to guarantee product consistency.

Tip: Find out what the published shelf life is on whatever conditioner you are using and follow that recommendation. Usually you can find the manufactured date somewhere on the container or packaging. If you're unable to locate it, or can't understand the numbers contact the manufacturer for assistance.

10. Environment

Definition - The set of circumstances that exist in your bowling center(s).

Finally we get to the big question; how do you know what conditioner is right for you or how do you properly apply the one you are currently using? The answer is…..Understand the circumstances that make up the ENVIRONMENT in your center. Here is a checklist of the items that determine conditioner selection and application:

Lane Machine Type

Lane Conditioner Type (Existing)

Lane Cleaner Type (Existing)

Dilution Ratio

Pattern and Cleaner Settings

Type of Surface

Condition of Surface (Be Honest!)

Topography (If Known)

What type of bowlers do you have in your center?

Where are your bowlers used to playing?

What are you looking to achieve by changing conditioner or your pattern?

These criteria will help guide you towards the solution. I wish I could tell you that there is a magic lane conditioner, but there isn't. I wish I could tell you that there is a magic lane pattern, but there isn't.

The best advice I can give would be to call the experts for help. Most manufacturers have one or more trained technicians on staff to help with this problem. For years, bowling centers have struggled with lane conditions independently trying to figure out this complicated problem with limited information.

Now there are places that are collecting data about many different situations to help bowling centers not make the same mistakes that another center has already made.

In conclusion, I don't think that the natural tendency of bowlers to look elsewhere for poor performance will ever change. But by gaining more knowledge on your part you can feel more comfortable when you say;

"I DID EM' THE SAME!"

Changing Out Conditioners - Sanction Technology

KEGEL TECH TIP - The following is Kegel's recommended procedure for changing out lane conditioners in Kegel Sanction Technology lane machines.

Remove the conditioner tank from the lane machine.

Empty the conditioner tank into a container. Do not reuse the old conditioner.

Remove the internal filter from the conditioner tank.

Flush the conditioner tank out with your lane cleaner solution to get any leftover conditioner and debris out of tank. Repeat this step at least one more time.

After the lane cleaner solution rinse, rinse the conditioner tank out with water until there are no more soap bubbles to ensure all lane cleaner residue is out of the tank.

Note: Kegel recommends NOT USING isopropyl alcohol or any other solvent.Allow the conditioner tank to dry completely.

Clean or replace the internal conditioner filter.

Reinstall the internal filter using Teflon tape and a small amount of clear silicone around the threads.

Reinstall the conditioner tank.

Fill the conditioner tank with the new conditioner.

Put the return line to the conditioner tank into a separate container and run the oil pump so that the old conditioner left in the lines will go into the container. This will force the old conditioner out of the conditioner tubing and replace it with the new conditioner while also keeping the old conditioner out of conditioner tank.

Once all of the old conditioner is out of the conditioner tubing, reinstall the conditioner return line back onto the conditioner tank.

Perform an oil volume output test five times into the separate container. This allows all of the conditioner to be removed from the pencil tip and conditioner tubing leading to the pencil tip.

Before applying conditioner to the transfer system components, and depending on your machines oil application, clean the transfer brush, smoother pads or transfer rollers, and the buffer brush. No chemicals should be used to clean these items; just clean dry towels.

Allow the conditioner pump to run and inspect all connections for any leaks.

Check your conditioner volume output and conditioner pressure. Kegel suggests setting the conditioner pressure at 15 psi for machines with a CPM2A and C200 PLC’s. However, anywhere between the ranges of 10-20 psi is safe. Machines that have a CP1H PLC will run conditioner pressure NO lower than 15 psi and no higher than 45 psi. And remember, conditioner pressure and volume are independent of each other - pressure differences WILL NOT affect conditioner volume.

For questions or assistance, please contact Kegel Tech Support US Toll Free at (800) 280-2695 or e-mail at tech@kegel.net

How to Choose the Correct Lane Conditioner

If there is one thing we have learned over the years, it’s that every bowling center is uniquely different. Even two bowling centers located right down the road from each other, using the same lane machine type, with the same lane surface, and using the same chemicals, can have drastically different lane conditions.

By measuring the lanes of hundreds of bowling centers with the Kegel LaneMapper™, we have begun to further understand why bowling centers can vary so much. However, things such as the water used to dilute the lane cleaner, the temperature and humidity within the building, and the different bowler types or balls being used by those bowlers can influence what lane conditioner is best for any one bowling center.

The properties Kegel tests on lane conditioners in the lab are all physical properties. Because all physical properties are affected by the environment they are used in, it is often hard to find or suggest the “right” lane conditioner without a little trial and error. So how do you begin to select the right lane conditioner and set-up for your bowling center?

First and foremost, our recommendation is that if you are happy with the lane conditioner you are using, don’t change it. If you are not happy however, and were to contact us at Kegel, there are a number of factors we would talk you about to get you on the right path. The following will give you some insight into the process we use to make lane oil recommendations to bowling centers.

The first thing we would ask is what problems you are experiencing in your bowling center. Issues that might indicate you need to change your lane conditioner are:

Excessive ball calls

Excessive out of ranges

Pattern is not holding up long enough

Pattern adjustments seem “too touchy”

Scores are not what they used to be

Before you switch your conditioner however, consider these possibilities:

Oil pattern: Some of the problems listed above could simply be caused by the oil pattern you are using. If you notice any of these issues, it is a good idea to have an expert review a copy of your current oil pattern to determine if this could be the source of the problem. Check out our pattern library or contact our tech support

Cleaner type, mix ratio, or residue:

Sometimes oil related issues can solely be a cause of a certain cleaner or mix ratio. Make sure the cleaner you are using is designed to remove the lane conditioner you are using.

ALL cleaners leave some residue behind - even those that claim to be residue free. For example, toilet bowl cleaners that keep your toilet “cleaner for longer,” leave a small amount of residue behind to help repel the dirt. Though the toilet may be flushed frequently and appear clean, the residue remains. For an example of this residue at work, watch this “Drop Shape” video to illustrate the effect cleaner residues can have on a surface.

Lane machine: Maintenance and upkeep of the lane machine are just as important as the chemicals they apply. Machines that are kept clean and maintained will apply conditioner more accurately and leave behind smaller amounts of residue.

Lane topography: We have a new saying at Kegel after measuring 1000’s of bowling lanes; “you can’t fix a gravity problem with oil.” Checking today’s synthetic lanes at 3 predetermined distances does not give enough information to determine how your lane’s shape affects ball motion. The consistency and predominant characteristic of your bowling center’s lane topography can finally be seen with the invention of the Kegel LaneMapper which can measure 744 points on the lane.

The top factors affecting lane play are the environment and pattern choices. After that comes the conditioner choice, followed by a third and often overlooked factor, the cleaner selection. Make sure you have exhausted alternate possibilities before chasing the perfect lane conditioner.

Lane Surface type:

Synthetic brand, model and age – AMF HPL’s or SPL’s, Brunswick’s many surfaces, DBA IQ™, Murray Pathfinder™, Switch, etc.

Wood lanes with finish - 100% solids, EZ Coat, moisture cure, water-based, etc.

Type of lane machine: Do you have a fluid metering lane machine (Kegel Sanction Technology), a wick/pad lane machine, or spray type machine?

Lineage: how much of your business is league play with high flaring modern bowling balls vs. open play with low flaring house balls. If more than 50% of your lineage is from league play, you should opt for a conditioner that has high durability. If your business is predominantly open play, parties, and social bowling events, look for a lane conditioner that is geared to prevent ball calls and out of ranges such as Prodigy.

Environmental factors:

Temperature consistency

Humidity

Cleanliness

Altitude

For example, if you live in a dry desert area, there is typically high static in the air which can cause lane play issues. In this scenario, it is good to look for an oil to help prevent the snappier back ends caused by the high static environment.

Through our experience with bowling centers all over the world, we have being exposed to many different scenarios. Although we have come to find that certain generalizations can be made based on the type of situation, no two centers are EXACTLY the same.

Dennis Sheirs, Vice President of Kegel’s Chemical division often gets asked the question “What is the best lane conditioner out there?” His response is, “the best lane conditioner is whatever works best in your center.”

When choosing a conditioner for your center, it is important to get advice specific to your factors in order to determine the best lane conditioner for your center, and ultimately, for your customers. As always, if you would like to have company along that journey trying to find that perfect lane conditioner, Kegel Technicians are only a free phone call away - Kegel Tech Support (800) 280-2695.

The Weather’s Changing…Are Your Lane Conditions?

It’s that time of year again. Leagues began towards the end of summer, the pattern gets tweaked, and everyone starts to get back into the swing of things. Everything is going great and then boom, the weather gets colder and all of a sudden things are different. Then comes the question every manager and mechanic has heard more than they can count - "What happened?"

The products that a bowling center uses to create optimal lane conditions; like lane machines, conditioners, cleaners, and even the lanes themselves, are all physical in nature and therefore temperature dependent. So as temperature changes, the properties and performance of all those products will change as well.

So how do changes in those physical properties show up in the bowling center? They show up in lane machine performance, oil pattern differences, lane topography changes, and of course, what the bowlers feel and see in ball reaction. As the temperature of the conditioner gets colder, the viscosity, surface tension, and density all increase which not only affects ball motion, this also affects different lane machines in different ways.

For this article, we will discuss these changes and offer advice on how to minimize the effects of cold weather on lane conditions. We will focus on the products used to condition the lanes, and in the next issue, we will move on to discuss the topographical changes the lane surface goes through as the climate changes.

Lane Conditioner

In early 1997, we conducted several tests to see how much conditioners changed when the temperature was raised or lowered. What we found was eye-opening. The viscosity of some conditioners changed 2 cps (centipoises) for every 1° F of temperature change. That means if you start with a 20 cps (viscosity) conditioner and the temperature drops from 80° F to 70° F, the viscosity of that conditioner would be 40 cps.

This is not true for all lane conditioners. Some only change 1 cp for every 2° F of temperature change. That is only 25% the change as some of the others, but regardless of how much they change, it's important to know that all of them do.

To minimize this change, look for a conditioner with a higher viscosity index (VI). VI is a way of assigning a value to a conditioner’s resistance in viscosity variation as the temperature changes. The manufacturer of your conditioner should be able to give you this value and guide you accordingly.

Lane Machines

For centers using wick technology lane machines, if the conditioner or lane machine is not kept at normal room temperature, or if stored near a cold wall, the oil will “thicken” and impede the wicking action which reduces conditioner flow onto the lane. As it gets colder, the capillaries in wicks shrink, also restricting flow. Therefore the oil pattern that you started out with at the end of summer might not be the same oil pattern as the weather gets colder.

For centers using Kegel Sanction Technology™, like the IKON, FLEX, and Kustodian line of lane machines, temperature decrease will not affect the output of conditioner like it will in a wick machine. However, if the conditioner gets colder, what you may see is the pressure in your oil pump gauge increase. Fortunately, this does not change the output of conditioner; that’s the beauty of Kegel’s Sanction Technology.

For Sanction Technology lane machine owners, Kegel’s Steve Cross suggests the following when seeing slight pressure fluctuations:

- DON'T PANIC! Expect pressure fluctuations because it is normal with temperature changes.

- Do not change the tubing (pressure regulator). Many people will try to put in a shorter tube to decrease the pressure, but this is not necessary. We have designed a large margin for psi and still have the machine perform as intended. Pressure alone does not affect oil output in Sanction Technology machines.

- Do not adjust the fluid metering pump to adjust pressure. Adjusting the fluid metering pump will increase and decrease the amount of conditioner output (volume).

- Get the machine out early, turn on the oil pump motor, and let it run for about 10 minutes. You should see the psi gauge go back to normal.

Our tech support department receives many calls this time of year with temperature related concerns and we recommend the following no matter what lane machine or lane conditioner you are using:

- Keep the lane conditioner in a temperature controlled environment. The office, front desk, or wherever the temperature is most constant.

- Keep on top of your chemical orders; try to place orders a few weeks in advance to give the chemicals a chance to “acclimatize.”

- Keep the lane machine in a temperature controlled environment so the machine functions properly. If that is not possible, look for other solutions like an electric blanket, packing blanket, or a space heater to help keep the machine warm.

Ball Motion

As we stated before, when conditioner gets colder, the viscosity, surface tension, and density increase. With the increase of these physical properties, more resistance is created on the bowling ball as it rolls through the conditioner. This, in return, usually causes the bowling ball to slow down faster which means it will hook a little more.

Another byproduct of colder weather is the conditioner tends to “stay in place” more which reduces carrydown and therefore, helps the backends stay stronger longer.

Not every bowling center is affected by outside temperature changes but if yours is, our technicians have a couple tips you can employ:

- If when the weather gets colder you notice the bowling balls are hooking more, increase your oil pattern by one foot. This will help bring back the hold area you had when the season began. Once the weather warms back up, decrease the pattern length back to what it was when the season began. Note: Wood lanes with overlays can change in shape which may increase this affect; read about "Changing Lanes".

- If you find temperature changes tend to affect your lane conditions, try to use a lane conditioner that is more resistance to temperature change (higher VI index). Kegel’s Offense HV (for Sanction Technology machines only) is such a product. Offense HV was created when Kegel was entrusted with lane maintenance for the PBA Tour. It was designed to minimize the difference in ball motion from the weekly competition to the TV Show. The TV Show uses many very hot lights that are not present during the rest of the week’s competition. To this day we use Offenses HV when we perform tournaments in venues with less than ideal climate control.

Keep in mind there is no magic lane conditioner or oil pattern that is best for every lane surface or bowling center. Finding a conditioner and oil pattern that is best for your center takes some research and a lot of patience. However, as a Kegel customer you have something going for you; award winning, industry leading tech support by Kegel’s 24/7 Tech Support. Best of all, it’s only a phone call away, and it’s free!