Oh No! My pattern is not playing the same as last year!

By Doug Dukes - Kegel Technical Sales Specialist and Kegel Pinsetter Parts

"My pattern is the same as last year but it is not playing the same" is one of the #1 lines we hear this time of year. As one of the techs at Kegel that has the privilege to not only help all of you on the phone, but to also work on lane machines in the field, let’s take a look at some overlooked parts and adjustments to your lane machine.

CLEANING - “You can’t paint the Mona Lisa on a piece of toilet paper.”

The number one overlooked problem on a lane machine is its ability to clean. Anytime a pattern adjustment is requested because they don’t play the same, our first question is “have you done a clean only”.

On Spray Jet machines, the screen check valves (153-0220) should be taken out regularly and cleaned. Lint build up on these can wreak havoc on the jet's ability to spray properly and as the check valves get weak, your spray tips can drip. If you notice that your machine is using less cleaner, it may be a good time to take these screens out and clean them. There are also two filters that cleaner passes through before it gets to the screen check valves, one in the tank (154-0212B) and one inline filter before the pump (154-8867A or 154-8887). It is always good to replace these filters every summer.

On Sprayless Cleaning Systems, you need to replace the two filters talked about above, but also your Norprene tubing in your cleaner pump (154-0861B). This style cleaner pump operates by using a set of rollers that press cleaner through this tubing every time the motor turns on. Over time, this tubing can lose its ability to allow cleaner to be pushed through it, and your volumes can be significantly reduced. Many times I have run a cleaner volume check on a lane machine and looked at the touchscreen only to realize that I was the last one to run the test during the yearly service last year!!! You guessed it……the volume was significantly lower than what it should have been.

Once you change the tubing, run a volume check and set it to your desired output and monitor this for a few weeks as the tubing breaks in. It will vary a bit during this time and a readjustment may be required, but it will settle in quickly. This should be checked on a regular basis throughout your season as well.

The cushion roller (153-8838 standard roller and 153-8839 roller with wrap), is another frequently overlooked piece to the cleaning puzzle. The size of the cushion is the key to your cleaning. If we think about how the cushion roller works, when the cloth unwinds, the cushion roller drops onto its stop bolts. When the machine is pushed onto the lane, the cushion actually lifts up off the stop bolts, and the weight of the cushion is what helps clean the lane. Simple right? If your cushion has gotten smaller over time, now it is not making full contact with the lane surface. This means it will not clean well. Mona Lisa and toilet paper soon to follow.

If you look at your cushion roller and see the “alligator skin” look, the ends are flaring out or torn and the cloth is visually pulling into the roller, or if you can wrap your hand completely around it, it is probably time to send it to greener pastures. One trick I show during service stops is releasing the tension on the cushion roller when you finish your lanes.

On machines that have the take up roll on the top, you can stand the machine in the transport position when finished and open the duster compartment. Slide the take up roll to the side and turn it 180 degrees and lock it back in place. This will relieve the pressure on the roller and when you turn the machine on to run lanes the next day, the machine will find “home” and wind the cloth back up for you. This can extend the life of your cushion and save you from headaches mid-season.

Squeegee blades (153-8204E Blue or 153-8834 Brown) normally are not overlooked, but why leave them out. Your squeegees should be flipped every six months, and changed once a year. You don’t want to leave any cleaner behind. Always check for your 1/8 to 3/16 adjustment as well, once you change or flip your blades and adjust accordingly.

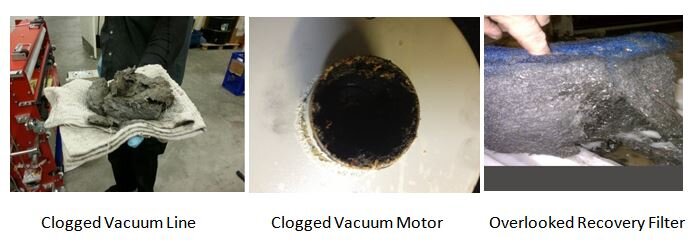

Recovery tank filters are another overlooked item in the cleaning process. Waste tank a little lighter than normal? Check your filter and change it regularly. This is the perfect time to flush out your vacuum hoses and check for small pin holes that may affect suction, along with cleaning your vacuum motor and checking the motor brushes.

Conditioning - “The best canvas deserves a worthy brush.”

A few minor adjustments in your transfer system that have been overlooked can also make you pull your hair out when you’re dialing in your pattern.

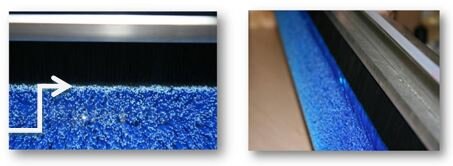

Have you checked your crush adjustments on your brush? Most people check the crush from the buffer brush to the lane and set their buffers at 1/8 to 3/16. What most people don’t check is the crush to the transfer brush or roller depending on the machine type. If it can’t pick it up off the transfer brush or roller it can’t get it to the lane!

As the brush wears, it may lose some contact with the transfer brush or roller. When getting ready for the fall season with an existing brush, or when putting in a new brush, always check this adjustment. We like to see 1/8 inch of crush to the roller or transfer brush.

On a transfer brush system, if you turn the buffer on while the brush is in the down position, you should see a thin light colored line where the transfer brush and buffer brush meet. This is from the bristles on the buffer brush being pushed together as they push against the transfer brush. Adjust accordingly.

Your pressure gauge can tell you a lot about your lane machine as well. If your pressure gauge fluctuates as you are applying loads or your pressure seems much higher than normal, you may need to clean your oil control valve. Dirt can accumulate in your valve over time and cause pressure fluctuations while applying loads. If the valve is dirty, take a good look at your filter inside your oil tank as well (154-0212). Replacing it once a year will keep you in top running order.

Your lane machine is one of the most important machines in your center. My final example I tend to give to proprietors and mechanics alike goes something like this…….

If one of your pinsetters happens to go down during a league, you may upset at most the 10 people that are bowling on that pair. But you probably have the parts to be able to fix this later that evening. If your lane machine goes down, and you have a 32 lane center that is full, you’ve now made 160 people upset, and you may NOT have the parts to fix it. You next day air the parts, but your still down the next night, and 160 turns into 320. It is extremely important that you keep your machine clean, do your daily and monthly preventative maintenance, and not take your lane machine for granted. Always keep a few parts on hand. One of every relay, two of every fuse, a fuse holder, a head drive belt, check valves, etc.

This minimal list of low-cost items can be the difference between a full house of happy bowlers, or a lynch mob and a quick backdoor exit of the center. Spend ten minutes a day, 20 minutes once a week, an hour a month and a half day every six months on your machine, and you will be able to keep it clean, and inspect the machine for wear on a regular basis. Always remember we are only a phone call away 24 hours a day 7 days a week from anywhere in the world. We are ALWAYS here to help.

Good luck and good scoring on your new season.

The Weather’s Changing…Are Your Lane Conditions?

It’s that time of year again. Leagues began towards the end of summer, the pattern gets tweaked, and everyone starts to get back into the swing of things. Everything is going great and then boom, the weather gets colder and all of a sudden things are different. Then comes the question every manager and mechanic has heard more than they can count - "What happened?"

The products that a bowling center uses to create optimal lane conditions; like lane machines, conditioners, cleaners, and even the lanes themselves, are all physical in nature and therefore temperature dependent. So as temperature changes, the properties and performance of all those products will change as well.

So how do changes in those physical properties show up in the bowling center? They show up in lane machine performance, oil pattern differences, lane topography changes, and of course, what the bowlers feel and see in ball reaction. As the temperature of the conditioner gets colder, the viscosity, surface tension, and density all increase which not only affects ball motion, this also affects different lane machines in different ways.

For this article, we will discuss these changes and offer advice on how to minimize the effects of cold weather on lane conditions. We will focus on the products used to condition the lanes, and in the next issue, we will move on to discuss the topographical changes the lane surface goes through as the climate changes.

Lane Conditioner

In early 1997, we conducted several tests to see how much conditioners changed when the temperature was raised or lowered. What we found was eye-opening. The viscosity of some conditioners changed 2 cps (centipoises) for every 1° F of temperature change. That means if you start with a 20 cps (viscosity) conditioner and the temperature drops from 80° F to 70° F, the viscosity of that conditioner would be 40 cps.

This is not true for all lane conditioners. Some only change 1 cp for every 2° F of temperature change. That is only 25% the change as some of the others, but regardless of how much they change, it's important to know that all of them do.

To minimize this change, look for a conditioner with a higher viscosity index (VI). VI is a way of assigning a value to a conditioner’s resistance in viscosity variation as the temperature changes. The manufacturer of your conditioner should be able to give you this value and guide you accordingly.

Lane Machines

For centers using wick technology lane machines, if the conditioner or lane machine is not kept at normal room temperature, or if stored near a cold wall, the oil will “thicken” and impede the wicking action which reduces conditioner flow onto the lane. As it gets colder, the capillaries in wicks shrink, also restricting flow. Therefore the oil pattern that you started out with at the end of summer might not be the same oil pattern as the weather gets colder.

For centers using Kegel Sanction Technology™, like the IKON, FLEX, and Kustodian line of lane machines, temperature decrease will not affect the output of conditioner like it will in a wick machine. However, if the conditioner gets colder, what you may see is the pressure in your oil pump gauge increase. Fortunately, this does not change the output of conditioner; that’s the beauty of Kegel’s Sanction Technology.

For Sanction Technology lane machine owners, Kegel’s Steve Cross suggests the following when seeing slight pressure fluctuations:

- DON'T PANIC! Expect pressure fluctuations because it is normal with temperature changes.

- Do not change the tubing (pressure regulator). Many people will try to put in a shorter tube to decrease the pressure, but this is not necessary. We have designed a large margin for psi and still have the machine perform as intended. Pressure alone does not affect oil output in Sanction Technology machines.

- Do not adjust the fluid metering pump to adjust pressure. Adjusting the fluid metering pump will increase and decrease the amount of conditioner output (volume).

- Get the machine out early, turn on the oil pump motor, and let it run for about 10 minutes. You should see the psi gauge go back to normal.

Our tech support department receives many calls this time of year with temperature related concerns and we recommend the following no matter what lane machine or lane conditioner you are using:

- Keep the lane conditioner in a temperature controlled environment. The office, front desk, or wherever the temperature is most constant.

- Keep on top of your chemical orders; try to place orders a few weeks in advance to give the chemicals a chance to “acclimatize.”

- Keep the lane machine in a temperature controlled environment so the machine functions properly. If that is not possible, look for other solutions like an electric blanket, packing blanket, or a space heater to help keep the machine warm.

Ball Motion

As we stated before, when conditioner gets colder, the viscosity, surface tension, and density increase. With the increase of these physical properties, more resistance is created on the bowling ball as it rolls through the conditioner. This, in return, usually causes the bowling ball to slow down faster which means it will hook a little more.

Another byproduct of colder weather is the conditioner tends to “stay in place” more which reduces carrydown and therefore, helps the backends stay stronger longer.

Not every bowling center is affected by outside temperature changes but if yours is, our technicians have a couple tips you can employ:

- If when the weather gets colder you notice the bowling balls are hooking more, increase your oil pattern by one foot. This will help bring back the hold area you had when the season began. Once the weather warms back up, decrease the pattern length back to what it was when the season began. Note: Wood lanes with overlays can change in shape which may increase this affect; read about "Changing Lanes".

- If you find temperature changes tend to affect your lane conditions, try to use a lane conditioner that is more resistance to temperature change (higher VI index). Kegel’s Offense HV (for Sanction Technology machines only) is such a product. Offense HV was created when Kegel was entrusted with lane maintenance for the PBA Tour. It was designed to minimize the difference in ball motion from the weekly competition to the TV Show. The TV Show uses many very hot lights that are not present during the rest of the week’s competition. To this day we use Offenses HV when we perform tournaments in venues with less than ideal climate control.

Keep in mind there is no magic lane conditioner or oil pattern that is best for every lane surface or bowling center. Finding a conditioner and oil pattern that is best for your center takes some research and a lot of patience. However, as a Kegel customer you have something going for you; award winning, industry leading tech support by Kegel’s 24/7 Tech Support. Best of all, it’s only a phone call away, and it’s free!

Bowling Bedlam - Oil

The playing environment of bowling today may be as complex, unpredictable and chaotic as any time in the history of the game. We're not talking about the weekly league or club game where the participants just want to have fun. We're talking about professionally maintained and controlled tournament environments where bowling sports people compete.

It is in this type of sporting environment, along with the basic premise of playing well both physically and mentally, that the decisions the modem player makes will ultimately determine whether they perform up to their expectations or have to wait until the next event comes around.

This is the second in a series of articles that will try to shed some light on many of the variables in the current game of bowling and why the players of today need to be very open minded and aware of the total environment at all times when competing. The supplied information is all in the quest of understanding and to increase performance, not to create excuses.

Oil (Conditioner)

There are low viscosity oils and high viscosity oils. There are oils with different amounts of additives such as friction modifiers and flow agents for different types of lane machines. There are oils with varying surface tensions which help the oil bond to the lane surface.

Mineral oil is used in most lane conditioners as the base oil but over the years lane conditioner has evolved. Today's conditioners are now mixed with a percentage of specialized additives to increase the performance and durability of the conditioner.

All these different types of conditioners will make your bowling ball react differently on the lane. At the same time, different types of conditioner can make the same pattern play different.

If using a wick machine, some conditioners will flow through the wicks more than others making the same pattern settings apply a different pattern. With wick machines, temperature will affect the flow rate since temperature not only affects viscosity or the thickness of the conditioner, it will affect the size of the capillaries of the wicks as well.

If using spray type machinery, different conditioners will either peel off or hold onto the buffer brush more or less which can change the shape of any specific pattern even though the machine settings remain constant. Different lane surfaces will do the same thing so add that into the equation also.

There is a very good online article by Kegel's Chris Chartrand on lane conditioner (oil), "10 Things That Everyone Should Know about Lane Conditioners" which you can view by clicking on the title. Therefore we won't go into specific details on all conditioner properties but one thing we will touch base on is viscosity since the USBC has just made a new specification on this lane conditioner property.

The new viscosity rule the USBC has implemented "requires that lane conditioners used during USBC competition read between 12 and 81 centipoises at 70 degrees Fahrenheit." Centipoise (cps) is the standard unit of measurement for fluids and many lane oil manufactures will have this designated on their product.

Viscosity is very misunderstood in common bowling discussions. Most bowlers believe the higher the viscosity of oil, the "slicker" the bowling ball reacts to it. Actually the exact opposite happens.

By definition, viscosity is the measurement of internal friction of a fluid. The greater the amount of friction, the more force is required to move the fluid against itself which is called shear. Therefore the higher the viscosity, the more force it takes which increases friction. The lower the viscosity of oil, the less force it takes to shear which decreases friction.

In terms of a bowling ball rolling through these different oils, the higher the viscosity, the more resistance there is which makes the ball slow down more. When we get to the bowling ball portion of the series, we will spend more time on this subject but in short, friction is what makes the ball slow down and therefore enables it to hook.

Temperature is one of the biggest environmental factors in changing viscosity of a conditioner. So as the weather changes, so can the bowling conditions.

So what is the purpose of viscosity in lane oils? In short to provide durability to an oil pattern however, because of the many different additives being used in today's oils, viscosity is not as important as it once was in regard to lane maintenance. But as a bowler, you should be aware of how it relates to ball motion.

Oil Patterns

This subject of oil patterns is a difficult one and probably the most blamed and misunderstood subject in bowling. Lane conditioning rules have changed many times over the years and even today with the USBC 'three unit rule' or the USBC Sport Bowling rule in place, there are an infinite number of pattern combinations and ways to apply an oil pattern to the lane.

Kegel's Founder and CEO John Davis had a saying when he was entrusted in doing lanes over the years which goes something like this;

"Its 4 o'clock in the morning and the tournament starts at 8:00. You know if you do this; this might happen. But if you do something else, that might happen. So what are you going to do? Who do you call? Who can you call? You have to do something but there is no book. It is all up to you."

In these simple questions lies the major dilemma for every laneman at every bowling tournament in the world. Only after the tournament do they ever know if the job was socially acceptable or unacceptable. In simpler words, did the laneman do a good job or a bad job?

Of course the laneman might ask the same question to the bowlers; when trying to figure out the conditions, did the bowlers do a good job or a bad job?

What is "Process Verification" and Why do We do it?

There are four questions on the minds of competitive bowlers at every event in the world:

1. Who chose this condition?

2. What right did he or she have to do this?

3. What was the motivation of the person choosing?

4. Were the lanes conditioned the same from week-to-week, day-to-day, squad-to-squad, or was an adjustment made to change the outcome of the event?

It seems to me, that in order to make a dent in our psychological attitudes, these four questions need to be answered, and the answers need to be accepted.

For question number four we now have a solution. In the past, the lane maintenance person’s word has been questioned because of perceived changes in ball reaction. He/she never wins that one. We have found that there are many reasons why the lanes may be done the same, but ball reaction is different.

With the invention of Kegel’s Sanction Technology™, we can now prove the pattern is exactly the same every time. This is a huge step forward in understanding bowling's technical challenges because it eliminates the applied oil pattern as a variable.

Therefore, if the ball reaction is perceived by the players to have changed from the previous fresh condition, we can then look at variables other than the applied oil pattern.

When Kegel is in charge of conditioning the lanes for tournaments and events, we follow what we call the “Process Verification Procedure.” What this means is the process of cleaning and conditioning the lanes is verified. This ensures to the players that the same procedures are being followed each and every time we perform lane maintenance for an event.

Process Verification Procedure (PVP)

Inspection of the lane cleaning.

Ensure the oil program is correct in the lane machine computer.

Perform the oil calibration check. This is a procedure where the oil that would normally go onto the lane is captured into a graduated cylinder for exact measurement. The amount of oil is calculable and verifiable from the desired oil program.

Walking with the lane machine to ensure the machine operation is the same on each lane. This is done by looking at the valve time, the speed of the machine, and the total run time of each lane.

Look on each lane to make sure the oil pattern distance and the look of the oil pattern is the same on each lane.

Taking lane tapes at specific distances to make sure the lane machine applied the oil pattern as intended.

The tournament technical delegate/representative and lanes person then signs-off that nothing in the procedure has changed and is as intended.

By performing this procedure time after time, we not only protect the integrity of the lanes person, we also protect the integrity of the player, and most importantly as it relates to lane conditioning, the sport of bowling.