You just push the button...right?

As I sit in the back of another bowling center, maintaining lanes for another tournament, I have been thinking about that famous line above, partially because I have already heard it at least once today. There are so many stories…some funny, not so funny, and some downright scary if you were in my shoes. I thought a glimpse of what we do behind the scenes could be an eye opener for many. Making things run smooth through chaos can be our biggest attribute sometimes.

The tournament I am currently at is a great example of the time put in outside of actually running lanes. Starting with a flight across the Atlantic and getting off the plane as first light breaks in Europe, which can be OK for those that can sleep on planes. My mind before an event however, runs 100 MPH, so that never happens. Explaining the Lane Mapper to the agent withholding it in luggage was easy THIS trip…first hurdle.

After arriving at the bowling center and plugging in my batteries for the mapper, I realize the charger isn’t working. The adapter that I brought is not converting voltage properly, so a quick google search of local hardware stores and off I go, many Euro’s later, we are in business. I finished mapping half the house around 4pm local time, just in time to head back to the hotel to find there was a new windows update pushed out that wouldn’t allow the PDA from the mapper to connect to the computer. Hacking windows registries until almost midnight and that problem is solved. The bowlers will be happy; they can have their lane map, barring nothing else tries to get in my way.

Arriving the following morning, or same morning if you like semantics, the mapping is finished. Setup the machines, run all the tests and calibrations, study the maps, pick a pattern. Out by 5:00pm, it’s a good day!!!!

Once the tournament starts, it’s the normal day to day obstacles, bowlers take more time than anticipated and we run two machines and catch things up so squads start on time. In 11 days I will be back in the US to start all over again. No rest for the weary.

Thinking of previous events as well, it’s normally not the machines that we deal with when we have problems. I remember going to a major event and doing a test clean on the first set of lanes for testing. I honestly thought something was wrong with my machine. I ran the second machine I had with me and saw the lanes had the same look as the first I did a strip only on.

At first I thought the lanes had a delamination problem, but upon further inspection, there was a film on the lanes from 10-10 that I couldn’t pull up. I scratched it with my finger nail and was able to remove it, but the lane machine would not. Running down the list of things to do. I tried straight cleaner with a rag by hand, that didn’t work. IPA with a rag by hand, two strikes. I don’t like to strike out, so it was time to call the chemical engineer back at the office!

After a few pictures, and a lengthy conversation, she asks me to grab some vinegar from the snack bar. We let it sit on the lane for a few minutes and to my surprise, the film came right off. This means I needed a mild acid based cleaner to clean the lanes and remove the film. Not wanting to hurt the lane bed itself, we found a cleaner that would work from a local hardware store with a little more “potency”, and another problem is solved for the day. Granted I returned to the hotel smelling like a fresh pickle from using the vinegar as a test, but the bowlers would be happy at the end of the day so it was worth the trouble.

During the PWBA tour, I was at an event with one of the most attentive staff I had worked with in quite some time, which saved me from a disaster believe it or not. We had been charging the machines on the far side of the building for testing, and the first day of open practice. No issues all week and it was smooth sailing. I walk into the center after going to get breakfast and one of the staff pulls me aside and says they had moved some things around for my machines.

Apparently, they had some electrical work done earlier in the year for a renovation, and the water heater on the OTHER side of the building was tied to the outlet I had plugged my machines into. They never knew it, nor did I, and it hadn’t been an issue until the center was full of people going to the bathroom and washing their hands making the water heater turn on and ultimately tripping the breaker I had my machines plugged into. They happen to notice that the lights on my charger had gone out and started to investigate on their own. I guess their attentiveness was good on three fronts. They know what the water heater is linked to, people had hot water to wash their hands, and my machines got charged and didn’t die 4 lanes before I finished in the middle of a tournament. Kudos to them for saving me on that one.

What came out that example was a lesson learned, and I now carry a tester for loads and outlets that I use when I go to bowling centers. I had to laugh out loud as I typed that last line. A little known fact is a lot of the upgrades or changes that happen to machines come from the fact that we experience things in the field and want to make them better for the end user. Automatic shut offs after a certain period of time on battery operated machines, suction cups on drip pads, redesigns of certain parts, and numerous software changes based on scenarios we encounter just to name a few.

Lastly, as most know, Kegel provides lane maintenance for a multitude of tournaments, but JR Gold is the most brutal workout a lane technician can go through. No problems have occurred at this event over the years that are worth writing about, but just to give you an idea of the schedule we maintain; seven days of up at 3:30am, pushing the button by 4:30am, and staying at the bowl until 8:30pm through multiple re-oils. We provided 4 of the 8 lane technicians, 16 brand new machines, did almost 14,000 lanes, and we also provided and went through over 50 cases of oil and cleaner. This is equivalent to what a 40 lane bowling center does in 1 year in a week!!! Not to mention the 200+ lane tapes that were read over the course of the week.

Even through all of this, we answer questions for customers that may be at the centers with their children, do our paperwork and answer emails between squads; it is truly non-stop for a solid week. We would not however, have it any other way.

I can only hope that this small glimpse of what one lane technician has experienced over the years, will allow you to appreciate what we do. When my career is over, I could probably write a tell-all book that wouldn’t sell more than 10 copies but would be 200 pages long and one heck of a funny read for anyone in the business.

It all leads to one bottom line, we take pride in what we do, the builders in manufacturing take pride in what they do, and at the end of the day we all try to make things look seamless. Hearing the statement “you just push the button” is actually a compliment. If you walk into the bowling center and see me wrapping up lanes for a tournament and you can say, “You have it made, all you have to do is push a button”, then I have done my job well.

"Is Your Center Fundamentally Sound" The View from a Coach

As a coach that travels the country for a better part of the year, and walks into unfamiliar bowling centers on a weekly basis, I hope to shed some light on what a coach really sees in your center, and what you can do as a mechanic to help bring tournaments back to your center year after year. Sitting in a hotel room now writing this, many thoughts run through my mind about what the start of a tournament tomorrow will bring.

Walking though the doors tomorrow I will immediately walk over to our starting lanes. A quick glance of the lanes themselves will give me an idea of how the mechanic prides himself on his daily duties. The first things I will look at are the gutters (not because we will be in them all day), then approaches, and finally the first foot of the lane surface. You may be shaking your head by now, but take a second to think about something… Freshly dusted gutters tell me someone cares about their job and how their center looks to newly invited guests, as do approaches that are spotless, and the fact that someone took the time to clean the first foot of the lane that the machine can not clean.

As the pinsetters fire up for open practice, every lane my players bowl on, they check the foul lights. A foul can be the difference between winning a match or losing by a stick. Did the mechanic take the time to check and inspect every unit before competition started? Since our practice is 20 minutes across the house and followed by ten minutes on our starting pair, I take the first half of the open practice to write in my notebook taking notes on lanes that set pins off spot on full racks, pins that wobble on a 2nd ball cycle, other players that are having sliding issues and how this can affect my team during a tight match where a key spare needs to be made. Your goal as a mechanic is to never give me the right to use my pen.

My ears are trained as a mechanic myself, I don't want to hear multiple calls to the back, nor do I want multiple malfunctions to hinder our fast paced style of play. Bowling for 6 hours and being on our feet all day is long enough without the hassles of waiting for multiple stops on multiple lanes. Believe me when I say at the end of the day I hear all of the good and bad from a variety of coaches on how a center runs. Most coaches are bowlers, and bowlers don't understand the mechanical side of a pinsetter. They expect it to go up and down, return their ball, and work perfect every time they throw a ball. As a mechanic you should provide that experience to the people that are helping to pay your wages.

Take the time in the weeks prior to your event and check your pin spots. Go through a morning routine and reset all of your lanes using the reset button to make sure it works, and watch your racks to make sure all pins are set on spot on a first and second ball cycle. Turn the foul lights on and check them your self and correct any problems you may find. Check all of your hand dryers to make sure they work properly. This will cover most of the front-end things that we see as coaches and competitors, but take it a step further. Inspect your kickbacks for screw heads that may cause ball damage as well as your ball tracks and any transitions (nothing is worse than scoring well and having a screw head take out part of your thumb hole which takes that ball out of your line-up, been there and have the t-shirt). Make sure your parts inventory is stocked so one small part doesn't make a lane go black for the weekend. Go over your stop sheets and make hot lists to fix any minimal problems such as nagging 180 stops, ball returns, or dreaded blackouts. On the day of competition get to the center in time to clean your gutters, clean your approaches, and take pride in doing your lanes and cleaning that first foot that your reliable lane machine can't get to.

In a coaches eye, I don't want to use my notebook to document off spot pins or approach issues, I want to use it to record my moves and ball changes to better me through out my competition weekend. I want to spend my time focusing on my players and their games, not what I would have done as a mechanic to make things better. If I can spend my entire day focusing on how to make my players win, then your bowling center is fundamentally sound and you have the coach's approval.

Oh No! My pattern is not playing the same as last year!

By Doug Dukes - Kegel Technical Sales Specialist and Kegel Pinsetter Parts

"My pattern is the same as last year but it is not playing the same" is one of the #1 lines we hear this time of year. As one of the techs at Kegel that has the privilege to not only help all of you on the phone, but to also work on lane machines in the field, let’s take a look at some overlooked parts and adjustments to your lane machine.

CLEANING - “You can’t paint the Mona Lisa on a piece of toilet paper.”

The number one overlooked problem on a lane machine is its ability to clean. Anytime a pattern adjustment is requested because they don’t play the same, our first question is “have you done a clean only”.

On Spray Jet machines, the screen check valves (153-0220) should be taken out regularly and cleaned. Lint build up on these can wreak havoc on the jet's ability to spray properly and as the check valves get weak, your spray tips can drip. If you notice that your machine is using less cleaner, it may be a good time to take these screens out and clean them. There are also two filters that cleaner passes through before it gets to the screen check valves, one in the tank (154-0212B) and one inline filter before the pump (154-8867A or 154-8887). It is always good to replace these filters every summer.

On Sprayless Cleaning Systems, you need to replace the two filters talked about above, but also your Norprene tubing in your cleaner pump (154-0861B). This style cleaner pump operates by using a set of rollers that press cleaner through this tubing every time the motor turns on. Over time, this tubing can lose its ability to allow cleaner to be pushed through it, and your volumes can be significantly reduced. Many times I have run a cleaner volume check on a lane machine and looked at the touchscreen only to realize that I was the last one to run the test during the yearly service last year!!! You guessed it……the volume was significantly lower than what it should have been.

Once you change the tubing, run a volume check and set it to your desired output and monitor this for a few weeks as the tubing breaks in. It will vary a bit during this time and a readjustment may be required, but it will settle in quickly. This should be checked on a regular basis throughout your season as well.

The cushion roller (153-8838 standard roller and 153-8839 roller with wrap), is another frequently overlooked piece to the cleaning puzzle. The size of the cushion is the key to your cleaning. If we think about how the cushion roller works, when the cloth unwinds, the cushion roller drops onto its stop bolts. When the machine is pushed onto the lane, the cushion actually lifts up off the stop bolts, and the weight of the cushion is what helps clean the lane. Simple right? If your cushion has gotten smaller over time, now it is not making full contact with the lane surface. This means it will not clean well. Mona Lisa and toilet paper soon to follow.

If you look at your cushion roller and see the “alligator skin” look, the ends are flaring out or torn and the cloth is visually pulling into the roller, or if you can wrap your hand completely around it, it is probably time to send it to greener pastures. One trick I show during service stops is releasing the tension on the cushion roller when you finish your lanes.

On machines that have the take up roll on the top, you can stand the machine in the transport position when finished and open the duster compartment. Slide the take up roll to the side and turn it 180 degrees and lock it back in place. This will relieve the pressure on the roller and when you turn the machine on to run lanes the next day, the machine will find “home” and wind the cloth back up for you. This can extend the life of your cushion and save you from headaches mid-season.

Squeegee blades (153-8204E Blue or 153-8834 Brown) normally are not overlooked, but why leave them out. Your squeegees should be flipped every six months, and changed once a year. You don’t want to leave any cleaner behind. Always check for your 1/8 to 3/16 adjustment as well, once you change or flip your blades and adjust accordingly.

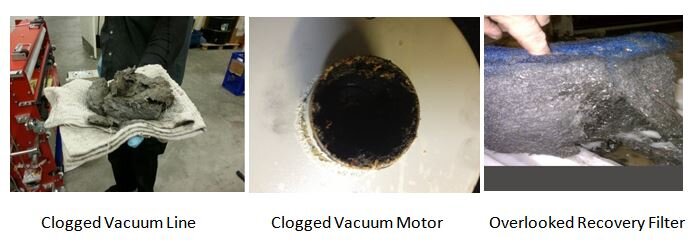

Recovery tank filters are another overlooked item in the cleaning process. Waste tank a little lighter than normal? Check your filter and change it regularly. This is the perfect time to flush out your vacuum hoses and check for small pin holes that may affect suction, along with cleaning your vacuum motor and checking the motor brushes.

Conditioning - “The best canvas deserves a worthy brush.”

A few minor adjustments in your transfer system that have been overlooked can also make you pull your hair out when you’re dialing in your pattern.

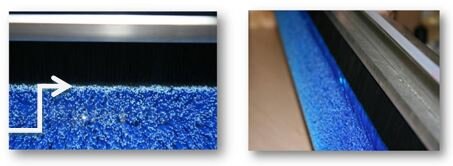

Have you checked your crush adjustments on your brush? Most people check the crush from the buffer brush to the lane and set their buffers at 1/8 to 3/16. What most people don’t check is the crush to the transfer brush or roller depending on the machine type. If it can’t pick it up off the transfer brush or roller it can’t get it to the lane!

As the brush wears, it may lose some contact with the transfer brush or roller. When getting ready for the fall season with an existing brush, or when putting in a new brush, always check this adjustment. We like to see 1/8 inch of crush to the roller or transfer brush.

On a transfer brush system, if you turn the buffer on while the brush is in the down position, you should see a thin light colored line where the transfer brush and buffer brush meet. This is from the bristles on the buffer brush being pushed together as they push against the transfer brush. Adjust accordingly.

Your pressure gauge can tell you a lot about your lane machine as well. If your pressure gauge fluctuates as you are applying loads or your pressure seems much higher than normal, you may need to clean your oil control valve. Dirt can accumulate in your valve over time and cause pressure fluctuations while applying loads. If the valve is dirty, take a good look at your filter inside your oil tank as well (154-0212). Replacing it once a year will keep you in top running order.

Your lane machine is one of the most important machines in your center. My final example I tend to give to proprietors and mechanics alike goes something like this…….

If one of your pinsetters happens to go down during a league, you may upset at most the 10 people that are bowling on that pair. But you probably have the parts to be able to fix this later that evening. If your lane machine goes down, and you have a 32 lane center that is full, you’ve now made 160 people upset, and you may NOT have the parts to fix it. You next day air the parts, but your still down the next night, and 160 turns into 320. It is extremely important that you keep your machine clean, do your daily and monthly preventative maintenance, and not take your lane machine for granted. Always keep a few parts on hand. One of every relay, two of every fuse, a fuse holder, a head drive belt, check valves, etc.

This minimal list of low-cost items can be the difference between a full house of happy bowlers, or a lynch mob and a quick backdoor exit of the center. Spend ten minutes a day, 20 minutes once a week, an hour a month and a half day every six months on your machine, and you will be able to keep it clean, and inspect the machine for wear on a regular basis. Always remember we are only a phone call away 24 hours a day 7 days a week from anywhere in the world. We are ALWAYS here to help.

Good luck and good scoring on your new season.