Bowling Bedlam - Oil

The playing environment of bowling today may be as complex, unpredictable and chaotic as any time in the history of the game. We're not talking about the weekly league or club game where the participants just want to have fun. We're talking about professionally maintained and controlled tournament environments where bowling sports people compete.

It is in this type of sporting environment, along with the basic premise of playing well both physically and mentally, that the decisions the modem player makes will ultimately determine whether they perform up to their expectations or have to wait until the next event comes around.

This is the second in a series of articles that will try to shed some light on many of the variables in the current game of bowling and why the players of today need to be very open minded and aware of the total environment at all times when competing. The supplied information is all in the quest of understanding and to increase performance, not to create excuses.

Oil (Conditioner)

There are low viscosity oils and high viscosity oils. There are oils with different amounts of additives such as friction modifiers and flow agents for different types of lane machines. There are oils with varying surface tensions which help the oil bond to the lane surface.

Mineral oil is used in most lane conditioners as the base oil but over the years lane conditioner has evolved. Today's conditioners are now mixed with a percentage of specialized additives to increase the performance and durability of the conditioner.

All these different types of conditioners will make your bowling ball react differently on the lane. At the same time, different types of conditioner can make the same pattern play different.

If using a wick machine, some conditioners will flow through the wicks more than others making the same pattern settings apply a different pattern. With wick machines, temperature will affect the flow rate since temperature not only affects viscosity or the thickness of the conditioner, it will affect the size of the capillaries of the wicks as well.

If using spray type machinery, different conditioners will either peel off or hold onto the buffer brush more or less which can change the shape of any specific pattern even though the machine settings remain constant. Different lane surfaces will do the same thing so add that into the equation also.

There is a very good online article by Kegel's Chris Chartrand on lane conditioner (oil), "10 Things That Everyone Should Know about Lane Conditioners" which you can view by clicking on the title. Therefore we won't go into specific details on all conditioner properties but one thing we will touch base on is viscosity since the USBC has just made a new specification on this lane conditioner property.

The new viscosity rule the USBC has implemented "requires that lane conditioners used during USBC competition read between 12 and 81 centipoises at 70 degrees Fahrenheit." Centipoise (cps) is the standard unit of measurement for fluids and many lane oil manufactures will have this designated on their product.

Viscosity is very misunderstood in common bowling discussions. Most bowlers believe the higher the viscosity of oil, the "slicker" the bowling ball reacts to it. Actually the exact opposite happens.

By definition, viscosity is the measurement of internal friction of a fluid. The greater the amount of friction, the more force is required to move the fluid against itself which is called shear. Therefore the higher the viscosity, the more force it takes which increases friction. The lower the viscosity of oil, the less force it takes to shear which decreases friction.

In terms of a bowling ball rolling through these different oils, the higher the viscosity, the more resistance there is which makes the ball slow down more. When we get to the bowling ball portion of the series, we will spend more time on this subject but in short, friction is what makes the ball slow down and therefore enables it to hook.

Temperature is one of the biggest environmental factors in changing viscosity of a conditioner. So as the weather changes, so can the bowling conditions.

So what is the purpose of viscosity in lane oils? In short to provide durability to an oil pattern however, because of the many different additives being used in today's oils, viscosity is not as important as it once was in regard to lane maintenance. But as a bowler, you should be aware of how it relates to ball motion.

Oil Patterns

This subject of oil patterns is a difficult one and probably the most blamed and misunderstood subject in bowling. Lane conditioning rules have changed many times over the years and even today with the USBC 'three unit rule' or the USBC Sport Bowling rule in place, there are an infinite number of pattern combinations and ways to apply an oil pattern to the lane.

Kegel's Founder and CEO John Davis had a saying when he was entrusted in doing lanes over the years which goes something like this;

"Its 4 o'clock in the morning and the tournament starts at 8:00. You know if you do this; this might happen. But if you do something else, that might happen. So what are you going to do? Who do you call? Who can you call? You have to do something but there is no book. It is all up to you."

In these simple questions lies the major dilemma for every laneman at every bowling tournament in the world. Only after the tournament do they ever know if the job was socially acceptable or unacceptable. In simpler words, did the laneman do a good job or a bad job?

Of course the laneman might ask the same question to the bowlers; when trying to figure out the conditions, did the bowlers do a good job or a bad job?

2008 EYC - When Everything Comes Together

The 2008 ETBF European Youth Championships at famed Tali Bowl in Helsinki Finland showed what can happen in the modern bowling environment when all parts of the scoring environment are predictable and at a high level. During the Championships, 12 of 15 girls scoring records were broken and 11 of 15 boys scoring records were broken. There were also five 300 games during the Championships. However, the closer you look and dissect the possible reasons why those records were broken and scores were achieved, the less anyone should be surprised.

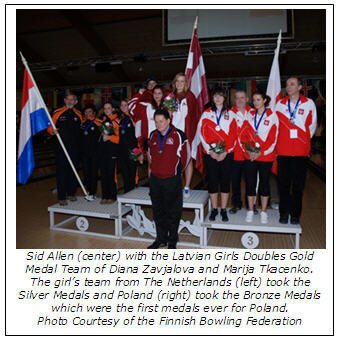

The Players

The youth players of Europe are more knowledgeable than ever and the overall level of coaching is at an all time high. Add to the fact that eastern European countries are increasing in participation numbers and they are treating bowling as a sport. Even world renowned coach Sid Allen has been attracted to Europe being hired as head coach of Latvia. This proved to be a great move on the Latvian Federations part as it helped them achieve the country’s first Gold Medals in Major Championship events. In fact Latvia won a total of five medals during the Championships, 1-Gold, 3-Silver and 1-Bronze. A fine testament to what a solid coaching program can bring to a Federation.

The Scandinavian countries have long been setting the standard in Europe by developing great player after great player. The Finns, Swedes, Norwegians and Danes all took medals in the boys divisions and from watching the youth competition at the 2008 EYC, the Scandinavian’s still are generating many great players.

But there are also some very good up and coming youth players from other parts of Europe because of solid coaching programs and Federation support. We should look forward to watching them in future European Championships and tournaments like the European Bowling Tour for many years to come.

Another item coming into place within Europe is increased equipment knowledge which is a huge part of being successful in the modern game. Until now and mostly because of language barriers, Europe as a whole has been behind the learning curve of countries where English is spoken or understood in high numbers. That however is changing and they are catching up fast as was evident by observing ball choices at this event.

The Lanes

But back to the environment, the scoring or playing environment that is. Tali Bowl is somewhat of an anomaly in the world of bowling. Built in 1972, the Finns might have known something very few knew, or at least practiced, about the installation of bowling lanes. Even after the replacement of the wood lanes to Pro Anvilane synthetic panels, all lanes at Tali Bowl consistently have a certain topographical characteristic and the key word here is “consistently.”

Many of the synthetic lanes we have checked over the years have showed very little regularity with regard to topography throughout any specific lane but not Tali Bowl, all lanes follow the same topographical features throughout the entire lane surface. When lanes are installed in as a consistent manner as they are at Tali Bowl, players have to adjust very little as they move across the center during any one block of bowling.

As Team Norway Coach Trond Syvertsen said, “Only thing we did, was not to move too much and keep the ball rolling forward.”

Just imagine not having to take one, two or even three frames to figure out how the next pair of lanes is playing in relation to the last pair and only having to concentrate on releasing the ball the same way. This adds a minimum of 10 pins to the scoring pace right off the bat.

As far as the specific topographical character of the lanes at Tali Bowl, lanes can be crowned, flat or depressed. But because it has been requested by Tali Bowl representatives to not make certain aspects of the installation public, here is how different types of topography act to a bowling ball.

Crowned lanes act like a banked curve that is falling away from the apex of the turn. You won’t see race tracks built this way but we do see many lane surfaces that are installed this way.

As the bowling ball travels towards the channel, crowned lanes decrease the pressure between the ball and the lane which also decreases friction. This decreased friction of the bowling ball keeps the ball from slowing down at the normal rate and therefore also decreases the hook potential of the bowling ball.

Basically, on a lane that is crowned the bowling bowl is rolling down a hill as it travels towards the channel and then has to climb a hill as it makes it moves towards the pocket. This topographical property also decreases pin carry because it lowers the entry angle of the bowling ball into the pocket.

Crowned lanes are also more sensitive to release variations or ‘mis-hits’ which can cause inconsistent ball motions for the less repetitious player. For right handed players, the 2-10 spare combination is a common leave on lanes that are crowned.

Flat lanes, or lanes that are in the plus or minus 10/1000 of an inch range, are very rare in synthetic lanes of today but there are actually a couple documented examples. One is the Kegel Training Center in Florida. The other is the bowling center that held the USBC 5 person team scoring record of 3905, Chacko’s Bowl in Wilkes-Barre, Pennsylvania. That record was broken in 2004 but Chacko’s is still the host to the USBC Men’s three player team series record of 2443. Flat lanes provide the most predictable ball motion for the greatest variety of styles.

Depressed lanes act like a high banked curve at a race track. Just like a banked curve helps a race car turn easier, depressed lanes help the bowling ball curve back to the pocket easier.

As the ball travels towards the channel, depressed lanes increase the pressure between the ball and the lane which also increases friction. This increased friction of the bowling ball helps the ball slow down and therefore hook into the pocket with more regularity. This not only helps with consistent ball motion, it also helps with pin carry because it increases the entry angle of the bowling ball into the pocket.

And last but certainly not least is the lengthwise levelness of bowling lanes. Lanes that predominantly go downhill from foul line to pin deck make the bowling ball slow down less and therefore decrease hook potential. Lanes that predominantly go uphill from foul line to pin deck make the bowling ball slow down more and therefore increase hook potential. As in crowns and depressions, flat lanes are the most predictable for most styles.

An example of how lengthwise level affects ball motion is a bowling center Kegel checked during their lane maintenance years on the PBA Tour. In this particular bowling center, the high end always played significantly tighter than the low end which had lanes that were added on after the initial installation.

After mapping the entire center, the difference was found to be in the lengthwise levelness of the lanes. All lanes in the high end went downhill almost two inches from foul line to pin deck. The lanes on the low end were relatively flat.

As stated in the opening paragraph of this section, the most important thing about a bowling center installation is “consistency” in lane levelness from the first lane to the last lane. For the bowling player, this gives the most predictable ball motion from lane to lane and that equals the highest scoring potential. If there is one thing we can say about the bowling lanes at Tali Bowl, they have very consistent topographical features from lane to lane.

The Pin Carry

Tali Bowl has long been known for good pin carry. The pins used during the 2008 EYC were Brunswick Max’s but it was not the pins that made the difference, it was the lane installation plus the entire pit area at Tali Bowl. The side boards (kickbacks) are tight, the pin decks are solid and the pin spotting was good.

The last 300 game bowled in European Youth Championship history in the boys division was, you guessed it, at Tali Bowl in 1994. The first and only 300 game by a European girl was last year in Thessaloniki Greece at another consistent lane installation but that bowling center has since closed down.

The Oil Pattern

Ah yes, the oil pattern. The one thing everyone likes to focus on because it is invisible and therefore open to discussion, controversy, interpretation or whatever analytical word one can come up with.

Being a mixed youth event that employed a single condition, the main goal for the 2008 EYC lane maintenance team was to provide a playing environment where many different bowling styles had a chance to succeed. In order for that to happen, it was important to provide an oil condition that complimented the lane surface.

The pattern used for the 2008 EYC was 39 feet in length as announced in Bulletin II. Standard procedure in ETBF Championship events is to announce only the distance based upon the pre-tournament inspection which is normally six to nine months in advance.

At the 2008 EYC, oil pattern information was transparently provided to the teams like never before. As usual the teams were provided the lane machine settings, the forward volume, reverse volume and the total volume of conditioner. However this time they were also provided with the front-to-back taper ratios and side-to-side ratios.

For all ratio readings, USBC Sport Bowling calculations were used which averages the unit amount of conditioner from boards 18L to 18R divided by the average unit amount from boards 3 to 7. Currently, USBC Sport Bowling has the only official guideline for competitive oil patterns in bowling and states side-to-side ratios must be 3:1 or less. The WTBA and ETBF do not have definite oil pattern specifications so the goal for the 2008 EYC was to hit the high side of the USBC Sport Bowling ratio parameters.

The front-to-back taper ratios at the 2008 EYC were 2.2:1 on the inside and 2.7:1 on the outside portion of the lane. This means in the front part of the pattern there is 2.2 and 2.7 times the amount of conditioner in those zones compared to the amount at the end of the pattern. A 3D visual of the oil pattern was also provided.

Also shown to the coaches and players were the side-to-side ratios from six different tape readings. The pattern ratios at the 2008 EYC were 2.5:1 at 6 feet, 2.9:1 at 14 feet, 3.0:1 at 22, 27 and 32 feet and 3.2:1 at 37 feet using USBC Sport Bowling calculations.

In comparison, the side-to-side ratios of the 2008 EYC pattern were the same as the 2007 PBA Greater Detroit Open and PBA Spartanburg Open. In those PBA events, the ratio at the end of the pattern was also 3.2:1 but all PBA tournaments must pass USBC Sport Bowling standards. Therefore, the 2008 EYC pattern also passes USBC Sport Bowling and was on the same difficulty level as those PBA patterns.

Conclusion

Too many people think scoring pace is all about the oil pattern. Of course the oil pattern can make the scores higher or lower but so do many other abovementioned areas of the playing field.

However, should we not just have some specific oil pattern parameters and let the scores be what they are? Bowling should not penalize a good installation and reward a bad installation because of a perceived perfect scoring pace and until now, that is what bowling has been doing.

The play and competition during the 2008 European Youth Championships was fantastic. There are many very talented youth players in Europe right now and all the record breakers and medalists should be very proud of their accomplishments because they earned it.

I also hope the players realize how lucky they were to be able to compete in an arena like Helsinki Finland’s Tali Bowl. It is arguably one of, if not the best, bowling arena in Europe. And the ETBF European Youth record book proves it.

Bowling Bedlam - The Lane

The playing environment of bowling today may be as complex, unpredictable, and chaotic as any time in the history of the game. We’re not talking about the recreational league or club game where the participants just want to have fun, and the conditions are designed as such. We’re talking about professionally maintained and controlled tournament environments where bowling sports people compete.

It is in this type of sporting environment, along with the basic premise of playing well physically and mentally, that the decisions the modem player makes will ultimately determine whether they perform up to their expectations or have to wait until the next event comes around.

The players of today have to choose how to execute their delivery using which type of bowling ball, with which layout, with what surface preparation, on what lane surface, with what lane characteristic, on which oil pattern, and following what group of players. The player must also change this strategy rapidly and often during any specific round of play or throughout the course of an event.

This series of articles will try to shed some light on many of the variables in the current game of bowling and why the players of today need to be very open minded and aware of the total environment at all times when competing. The supplied information is all in the quest of understanding and to increase performance, not to create excuses.

The Lane

There is no question bowling balls of today are more frictional, hook more, and cover more area across the lane as it travels from the foul line to the pins. The modern core designs and coverstock compositions create more friction, which also makes the bowling ball more responsive to all the different variables that make up the playing environment.

There are different types of plastic film coated wood lanes which are the softest lane surfaces. There are wood lane surfaces coated different types of urethane which are the next hardest lane surfaces. The hardest and most common lane surfaces around the world now are synthetic lanes, with many different installation and friction characteristics.

We won’t get to deep into the specific manufactured hardness, friction, or wear properties of synthetic lanes, but keep in mind that all manufactured synthetic lane surfaces are different and how those surfaces wear from use is also not equal.

The USBC has performed studies that show some modern synthetic lane surfaces score best when brand new, some score better after a few years, peak, and then begin to score worse, while other surfaces score higher as wear and friction increases.

In regard to topography, the sanding techniques on wood lanes make those lanes much flatter than that of the installation of multiple synthetic panels. When a particular bowling center employed a strict resurfacing program, with skilled resurfacers, all the lanes in the bowling center was of high-quality and fairly consistent.

It is therefore a fair statement to say that wood lanes that are consistently resurfaced, screened, and re-coated on a consistent basis are more level than the synthetic bowling lanes of today.

One might think the contrary when only thinking about the synthetic panel itself. But when multiple panels are attached in sections on top of structures made up of other wood components, and more often than not on top of older wood foundations, it is easy to see the challenge for consistent levelness across a center using synthetic overlays. But it’s not impossible to achieve.

The current lane specification rules were written in 1937 by the American Bowling Congress, for wood lanes. The basics of the rule are the entire lane must be less level within plus or minus 40/1000 of an inch to be certified and approved for sanctioned play. The idea was that any groove deeper than the specification would allow too much guidance, or path correction, of the bowling ball after it was released by the bowler.

These level number limits also apply to crowns (hills), depressions (valleys), crosswise tilts, and lengthwise levelness. Surprisingly, only recently has the lengthwise level specification been added into the rules. The 40/1000 inch specification now reads “over 42 inches in any direction”, but only for new installations or centers that are changing from wood lane surfaces to synthetic overlays.

However, the overwhelmingly majority of the lanes are still inspected and passed by inspecting the lanes at only three predetermined points. These three inspection points are at a distance from the foul line between 10’-15’, 30’-40’ and 50’-55’. It is of course at these predetermined inspection areas installers of synthetic lanes pay most attention to.

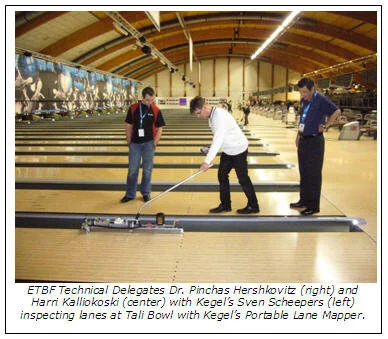

Of course there are some very good installations and installers of synthetic lanes today but the reality is, installations are only as good as the time and care that is taken on a particular installation. Since the advent of synthetic lanes, achieving consistent levelness throughout a bowling center is a very difficult painstaking task and the tools and technology to level lanes in a more efficient manner have not been available. (Note: The recent invention of the Kegel Portable LaneMapper has made this process more efficient and attainable.)

Long time laneman and former PBA Lane Maintenance Director Len Nicholson states, “I’ve seen synthetics installed in 4-6-hours and they were legal according to the Sanctioning Body. This was in bowling centers that were changing over to synthetic overlays after their wood surfaces have reached their life limit. However, when the arena settings started on the PBA Tour and companies like AMF and Brunswick wanted to showcase their synthetic lanes, it would take them up to two days to get them as perfect as they could. And they were using their best installers performing the job on only four lanes!”

As the bowling ball travels down the synthetic lanes of today, it has to go slightly uphill sometimes, and then downhill at other times. The ball encounters random patterns of hills, valleys, and it encounters microscopic frictional differences, all without any uniformity.

By performing tests at the Kegel Training Center’s adjustable lanes in 1999 with top PBA professionals such as Parker Bohn III, Brian Voss and Jason Couch, it was proving that as little as 20/1000 of an inch, or 25 percent of the allowable tolerances, will affect the path and reaction of today’s highly responsive bowling balls.

These seemingly minute irregularities can cause a ball to increase its footprint which increases the friction between the ball and the lane. This will make the ball slow down more therefore increasing the hook potential. These topographical irregularities may also decrease the footprint between the ball and the lane which causes less friction. This makes the ball slow down less therefore decreasing the hook potential.

These random irregularities can make your intended shot possibly either hit the pocket heavy, light or in extreme cases even miss the pocket entirely.

When oil patterns that are designed to play more towards the outside portion of the lane are applied to bowling lanes which are predominantly crowned on the outside boards, it is difficult for the bowling ball to hook back into the pocket. Most short oil patterns are designed this way, and crowned lanes can make those patterns more difficult. However on longer oil patterns, or patterns designed to play more towards the inside portion of the lane, crowned lanes can sometime act like hold area which can increase mistake area.

On the other hand, bowling lanes that are depressed from the edge board can act like a race track with high banked turns on short oil patterns. The highest scoring lanes for short oil patterns are when lane topography is either slightly depressed or flat.

On long patterns however, depressions can take away hold area and make a long pattern more difficult since the ball will have a tendency to hook more. That is unless the player is on the other side of the depression. Then a depressed lane acts like that same banked race track a depression gives a player on a short pattern.

Unfortunately, rarely do synthetic lanes have a consistent character with regard to topography which makes it a challenge for both the players and the laneman.

For tournament players, depending on what lane a player begins their round on, these lane differences may determine a player’s equipment choice for the day or even where to play with no likeness of another. These choices can and often will cause the oil pattern to change in a different manner from day to day, squad to squad, pair to pair and even lane to lane.

A scenario often seen in leagues and tournaments throughout the world is when there are perceived differences in ball reaction, total blame is put on the oil condition when in fact most times it is the difference in the topography, surface friction of the lanes, or even the bowler themselves.

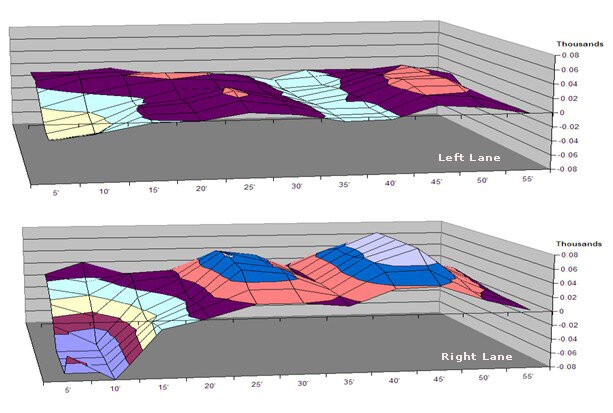

The below picture show a real world example of two lanes that make up a pair in a sanctioned bowling center.

The left lane of the pair is within specification, plus or minus 40/1000 inch, at most points throughout the lane. The right lane however has historically played notably different than its companion.

In this case, because of the extreme depression in the head area, and the excessive crowns in the mid lane and break point area of the lane, the right lane has always played considerably tighter. Basically the bowling ball is falling off the mountain in the midlane and then trying to climb the mountain as it begins it move towards the pocket. The depression in the head area also causes the ball to 'burn up' earlier which causes less back end movement. The players in this center say they are always lined up 4-5 boards different between these two lanes with the ball hooking much less on the right lane.

Take notice the points on the right lane that are within specification, which in this example are not many but only in the three aforementioned inspection areas. The left lane is also most level in those same three inspection areas.

Kegel has measured 1000’s of lanes and studied the scores of many different tournaments they have been associated with. They have found these topographical and frictional differences are the reason those “mystery pairs” tend to show up at bowling centers. It’s not always that those lanes or pairs are bad or out of specification and sometimes that one lane or those mystery pairs are actually flatter than all the other lanes. What makes them challenging is they are different than the others and players are trying to adjust to that one different lane off of all the others.

With all other things being equal, low scoring centers or tournaments are more about the lane surfaces throughout center being very irregular from lane to lane, while higher scoring can be more about the lane surface being very consistent from lane to lane.

In short, when centers have consistent topographical features from lane to lane, fewer adjustments from the players are needed.

Nicholson tells of an example from the PBA Tour at The Showboat in Las Vegas; “The TV Pair always played weird. The great PBA players always had problems. Scores on that pair were never up to par and eventually they changed the TV pair.”

If there is one thing you can take from this article, is to look at bowling lanes individually with each having their own unique characteristics. Don’t look upon a pair of lanes as both being the same or adjust to one lane in a pair off of the other lane unless you notice a specific trend in the center.

The balance between caring for the playing environment and it participants from the monetary pressures is one of bowling's sanctioning bodies’ greatest challenges. Our recreational fads will come and go with having to be continually reinvented to keep interest amongst those non-sporting customers. A healthy sport of bowling however will produce lifelong customers which every business person should want to create and sustain.

Topography: What does it all mean?

Topography - The Science of Representing the Features of a Given Surface.

Lane topography in today’s bowling environment is one of the most influential factors in ball reaction. In the past, when bowling balls did not grip the lane surface as much and therefore hook as much as today’s balls, lane topography was not as much of a factor. In short, the less the amount of overall hook, the less lane topography comes into play and the more the ball hooks, the more influence topography has on ball reaction.

The topography of a lane surface consists of three different types of measurements: Crosswise Tilt, Crowns & Depressions, and Lengthwise Level. Topography affects the ball reaction characteristics on each lane and is mostly responsible for those ever present "mystery lanes" you may encounter in a bowling center.

Crosswise Tilt

The United States Bowling Congress makes the rules covering lane specifications. All other Federations around the world follow the USBC in this regard. One such specification is the crosswise tilt, or the measurement from gutter to gutter which shows if one side of the lane is higher than the other side. The specification is plus or minus 40 thousandths (0.040) of an inch (1.106 mm). This is just over 1/32 of an inch.

The USBC provides special lane levels used in measuring and certifying bowling lanes. For crosswise tilt the level is laid across the lane, and the bubble of the level will move to the side that is high. Feeler gauges, ranging from 0.005 to 0.040 of an inch thick, are then placed under the low end of the lane level until the bubble is once again centered. The thickness of the gauges needed equals the amount of tilt on the lane.

The majority of lanes have some amount of tilt. While there may not be consistent tilt readings across all lanes in a particular center, there is often a degree of consistency on each lane, but not always. The amount the crosswise tilts affects the entire lane can be averaged between each arrow. Example: 0.040 thousandths tilt has an average value of 0.005 thousandths for every five board area.

The crosswise tilt becomes the greatest factor when the lane is tilted to one side for a certain length of the lane. The ball is more affected by the crosswise tilt from thirty feet to the pin deck as this is where the break point is or where the ball changes direction the most. It can have some impact in the front of the lane, but the tilt needs to be pretty large. (12-15-2009 edit: Recent testing and findings have changed this notion. Testing has found that the front part of the lane has as much, if not more, influence on ball motion and direction as any point throughtout the lane. In an area of less friction, less force is required to move an object off line. Newton's Laws of Motion)

In simpler terms, if a round object is placed on a flat level surface and then one side is raised, the object roll towards the low side. Remember, this is only one of the pieces of lane surface characteristics. Below are examples of crosswise tilts:

Crosswise Tilt - High Right

Crosswise Tilt - High Left

Crowns and Depressions

The crowns and depressions show the actual shape of the surface from gutter to gutter.

A crown is an increase in height from a given zero point. The peak of the crown, of course, is the highest point. The peak, however, is not necessarily the center of the lane. It can peak at any point across the lane. A crown, unlike crosswise tilt, is measured by the amount of change across each five-board area. This is also measured using the lane level with an attachment called the Dial Indicator. The indicator glides across the level reading the amount of rise or drop of the surface in thousandths of an inch. (12-15-2009 edit; with the invention fo the Kegel Lane Mapper, topography is now measured on each board instead across a five-board area.)

A crown can give the bowler a sense of hold but also takes away swing area. Like crosswise tilt, crowns have more influence when they remain consistent across a certain length of the lane. Crowns have a tendency to benefit players that do not cross a lot of boards. Two units of oil can feel like five units when the lane is crowned. The amount of pressure that the ball has against the lane is less when going away from the pocket but greater when more direct. It is like riding over a hill.

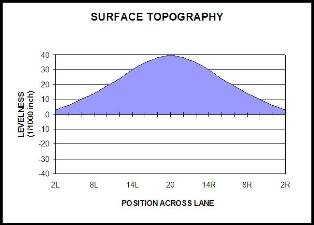

Example of a 0.040 inch Crown

A depression is the opposite of a crown. The shape is measured by the amount of decrease from the zero point. This concave shape allows bowlers to feel that there is more swing area but less hold. It can make a line near the gutter have more swing area. Basically, five units of oil can react more like two units of oil.

A depression can also force players to cross an increase number of boards. The pressure the ball feels on a depression is greater when crossing boards which increases friction between the ball and the lane. But a ball thrown on a more direct trajectory will have trouble reaching its break point because of this increased friction.

A depressed lane is very much like a banked turn on a race track. When an automobile or motorcycle hits the banked curve, it becomes easier to turn and also slows easier. The momentum of the vehicle is now compressed into the embankment.

Example of a 0.040 inch Depression

The USBC specifications for crowns and depressions are the same as crosswise tilt, plus or minus 0.040 of an inch.

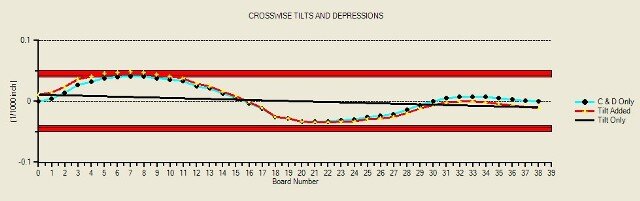

Crosswise Tilt + Crowns + Depressions readings at a distance of 42 feet from the foul line.

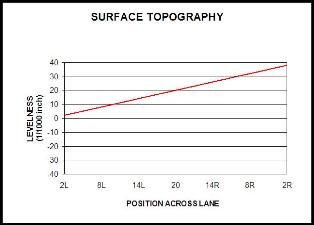

Lengthwise Level

The lengthwise level of the lane is the final piece in the topography puzzle. This can also have dramatic effects on ball reaction. This allows us to see how many hills and valleys the ball sees rolling down the lane. Like driving, the vehicle maintains or even increases speed when moving down a hill. It slows quite a bit when moving uphill. A lane that runs uphill or downhill from 30 feet to the pindeck will become more sensitive to speed changes. This is caused by the amount of surface pressure that the ball has against the lane. A lane going downhill can play tighter and an uphill lane can promote more hook.

Most lanes are installed using a carpenter’s string or a laser. One problem with a carpenters string is it will tend to show the lane is lower in the center than at the foul line and pin deck. In our data collection process we collect the lengthwise measurements every five feet, with a laser.

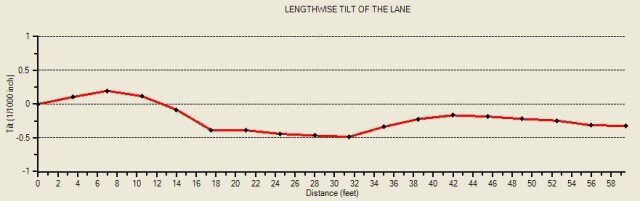

Example of a lane’s lengthwise level taken every 3.5 feet:

Three-in-One

When all three factors (crosswise tilt, crowns and depressions, and lengthwise level) are added together, many different things can happen. Each lane has some differences whether it is one or all of the three factors. Certain combinations of the three can have somewhat similar characteristics as a lane that has a different topography. Inequity can be seen in a surface and the level of a lane can give a certain style or side an advantage.

The patterns run for most high level competitive bowling events allow the topography to stand out. The patterns themselves normally do not provide much swing area or hold area, so we have an idea of what the reaction should look like. When we see something different, we could make the conclusion its the topography. It might also the way the players you are following are breaking down the oil pattern, but that is another discussion for another day.

Believe it or not, wood lanes tend to be the most consistent across a given center. The reason is the sanding equipment does not allow for significant changes from lane to lane. Most lane resurfacing machines have a fixed pattern for making cuts during the resurfacing process. But keep in mind, there can still be mystery lanes.

On the other hand, most would think synthetic lanes are the flattest surface currently on the market, but that is far from the truth. Lanes made up of multiple synthetic panels can, and are the majority of the time, be vastly different from lane to lane across a house. There are many reasons for these inconsistencies with synthetic lanes.

Reason #1: The Weather

Centers located in areas of the world that can experience large temperature and humidity changes from season to season, see the most changes in topography (both wood and synthetic). Even though the lanes are synthetic, they are still made of wood in one form or another. Substructures are made of a pressed board, and pressed fiberboard's (wood fibers). The actual surface is made up of sheets of pressed paper with a melamine layer that the ball touches. So the surface can absorb moisture from the air and it can dry out when the air is dry. All wood does this!

Reason #2: The Installation

How synthetic lanes are installed is very important. They may initially be consistent across the house. Eventually the lane takes abuse and gets exposed to environmental factors, explained above. Remember that a wood lane is one solid piece while the synthetics are separate pieces screwed together. An installer may tighten screws tight enough to dimple the surface and cause the areas not screwed down to "bubble" up.

All of these factors make up the topography of a particular lane surface which can and probably will influence the reaction of your bowling ball.

What is "Process Verification" and Why do We do it?

There are four questions on the minds of competitive bowlers at every event in the world:

1. Who chose this condition?

2. What right did he or she have to do this?

3. What was the motivation of the person choosing?

4. Were the lanes conditioned the same from week-to-week, day-to-day, squad-to-squad, or was an adjustment made to change the outcome of the event?

It seems to me, that in order to make a dent in our psychological attitudes, these four questions need to be answered, and the answers need to be accepted.

For question number four we now have a solution. In the past, the lane maintenance person’s word has been questioned because of perceived changes in ball reaction. He/she never wins that one. We have found that there are many reasons why the lanes may be done the same, but ball reaction is different.

With the invention of Kegel’s Sanction Technology™, we can now prove the pattern is exactly the same every time. This is a huge step forward in understanding bowling's technical challenges because it eliminates the applied oil pattern as a variable.

Therefore, if the ball reaction is perceived by the players to have changed from the previous fresh condition, we can then look at variables other than the applied oil pattern.

When Kegel is in charge of conditioning the lanes for tournaments and events, we follow what we call the “Process Verification Procedure.” What this means is the process of cleaning and conditioning the lanes is verified. This ensures to the players that the same procedures are being followed each and every time we perform lane maintenance for an event.

Process Verification Procedure (PVP)

Inspection of the lane cleaning.

Ensure the oil program is correct in the lane machine computer.

Perform the oil calibration check. This is a procedure where the oil that would normally go onto the lane is captured into a graduated cylinder for exact measurement. The amount of oil is calculable and verifiable from the desired oil program.

Walking with the lane machine to ensure the machine operation is the same on each lane. This is done by looking at the valve time, the speed of the machine, and the total run time of each lane.

Look on each lane to make sure the oil pattern distance and the look of the oil pattern is the same on each lane.

Taking lane tapes at specific distances to make sure the lane machine applied the oil pattern as intended.

The tournament technical delegate/representative and lanes person then signs-off that nothing in the procedure has changed and is as intended.

By performing this procedure time after time, we not only protect the integrity of the lanes person, we also protect the integrity of the player, and most importantly as it relates to lane conditioning, the sport of bowling.